Pin type power single tube integration scheme applied to electric control product of electric vehicle

A technology for electric vehicles and power, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of high price of packaged power modules, inconvenient detection of solder joints and tin beads, high failure rate of selective soldering, etc., and achieve light weight, Effects of low price and increased design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

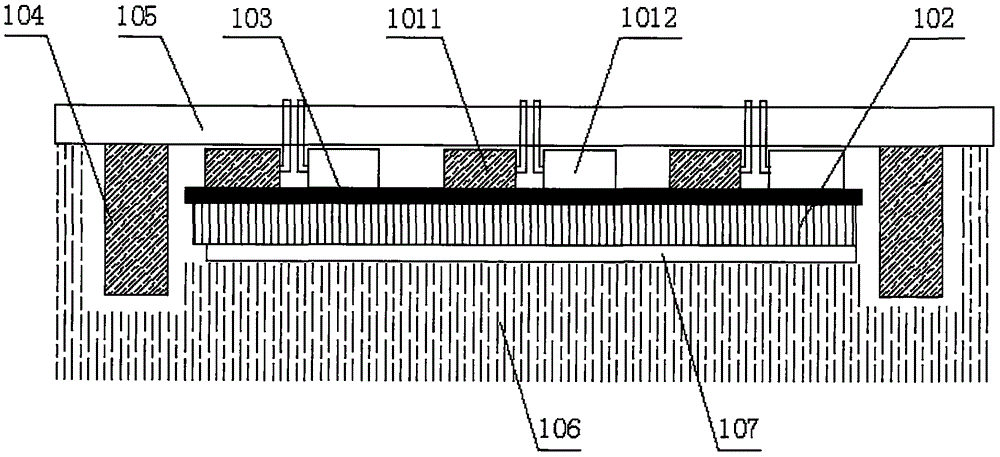

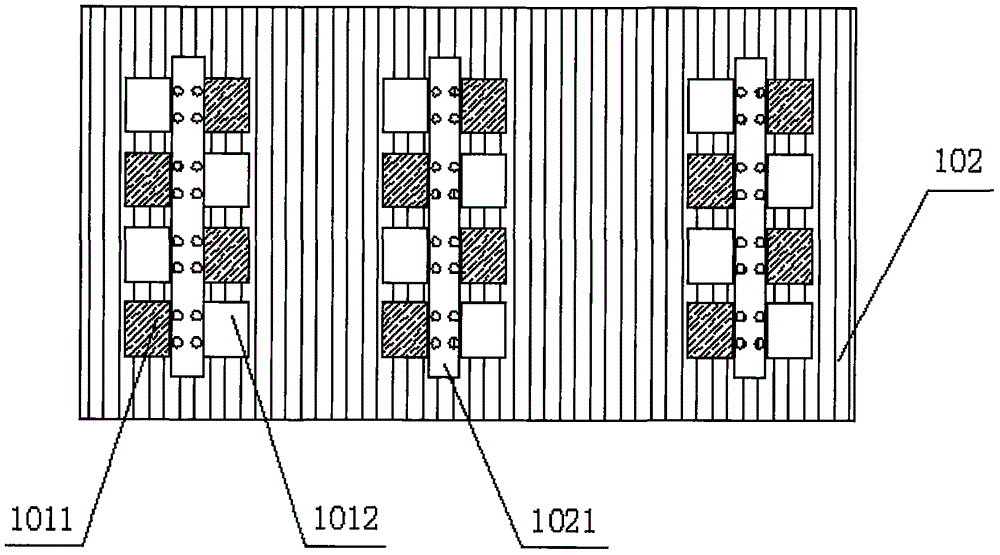

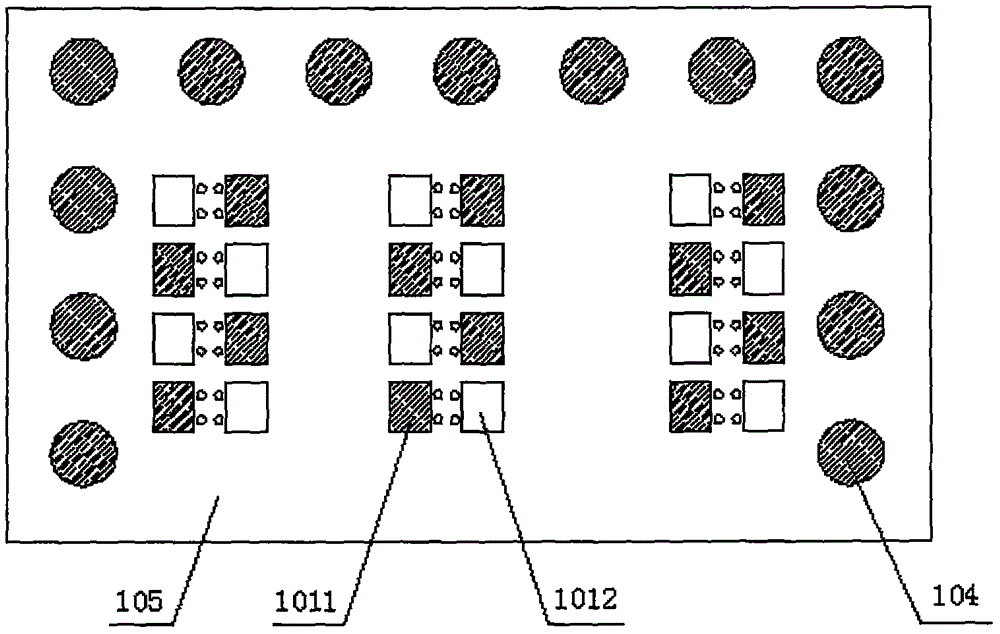

[0015] A pin-type power single-tube integration solution applied to electric vehicle electronic control products, such as figure 1 As shown, the pin-type power device is first crimped to the metal carrier 102 through a pressing sheet or a pressing bar, and an insulating and heat-conducting gasket 103 is provided between the power device and the metal carrier 102; then the power unit The pins of the tube and the bus capacitor 104 are welded on the thick copper PCB 105; finally, the metal carrier plate integrated with the thick copper PCB is crimped on the heat dissipation cold plate 106, and the metal carrier plate 102 and the heat dissipation cold plate 106 Thermally conductive silicone grease 107 is inter-coated.

[0016] Compared with the packaged power module, the price is low, the design flexibility is greatly improved, the feasibility of selective soldering or wave soldering of the single power tube is greatly increased, the weight is light, the heat capacity of the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com