Full-automatic intelligent-welding assembly line

A production line, fully automatic technology, applied in welding equipment, auxiliary equipment, metal processing, etc., can solve problems such as difficult quality assurance and low efficiency, and achieve the effects of reducing labor costs, accurate positioning, and improving product production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

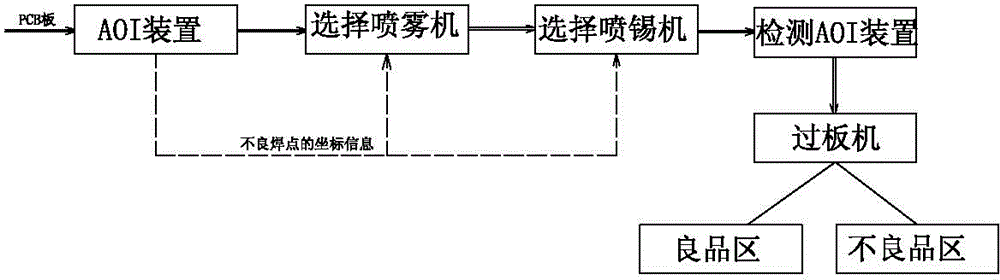

[0016] An intelligent welding automatic production line, including:

[0017] The AOI device is used to take pictures of the PCB board image and compare it with the good PCB board image, and calculate the coordinates of the bad solder points through software;

[0018] Choose a spray machine to spray flux on the bad solder joints on the PCB;

[0019] Select a soldering machine for correcting soldering of bad solder joints;

[0020] The transfer device is used to transfer the PCB board to the AOI device, the selective spray machine and the selective soldering machine in sequence.

[0021] During specific implementation, the transfer device sequentially transfers the PCB board to the AOI device, selects the sprayer, and selects the soldering machine. The transmission device first transmits the PCB board to the detection position of the AOI device. The AOI device takes pictures of the PCB board and compares it with the image of the good PCB board. The coordinates of the bad solde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com