Soldering apparatus

A technology of welding equipment and equipment, which is applied in the direction of welding equipment, metal processing equipment, tin feeding device, etc., and can solve the problems of reduced working hours and frequent production lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

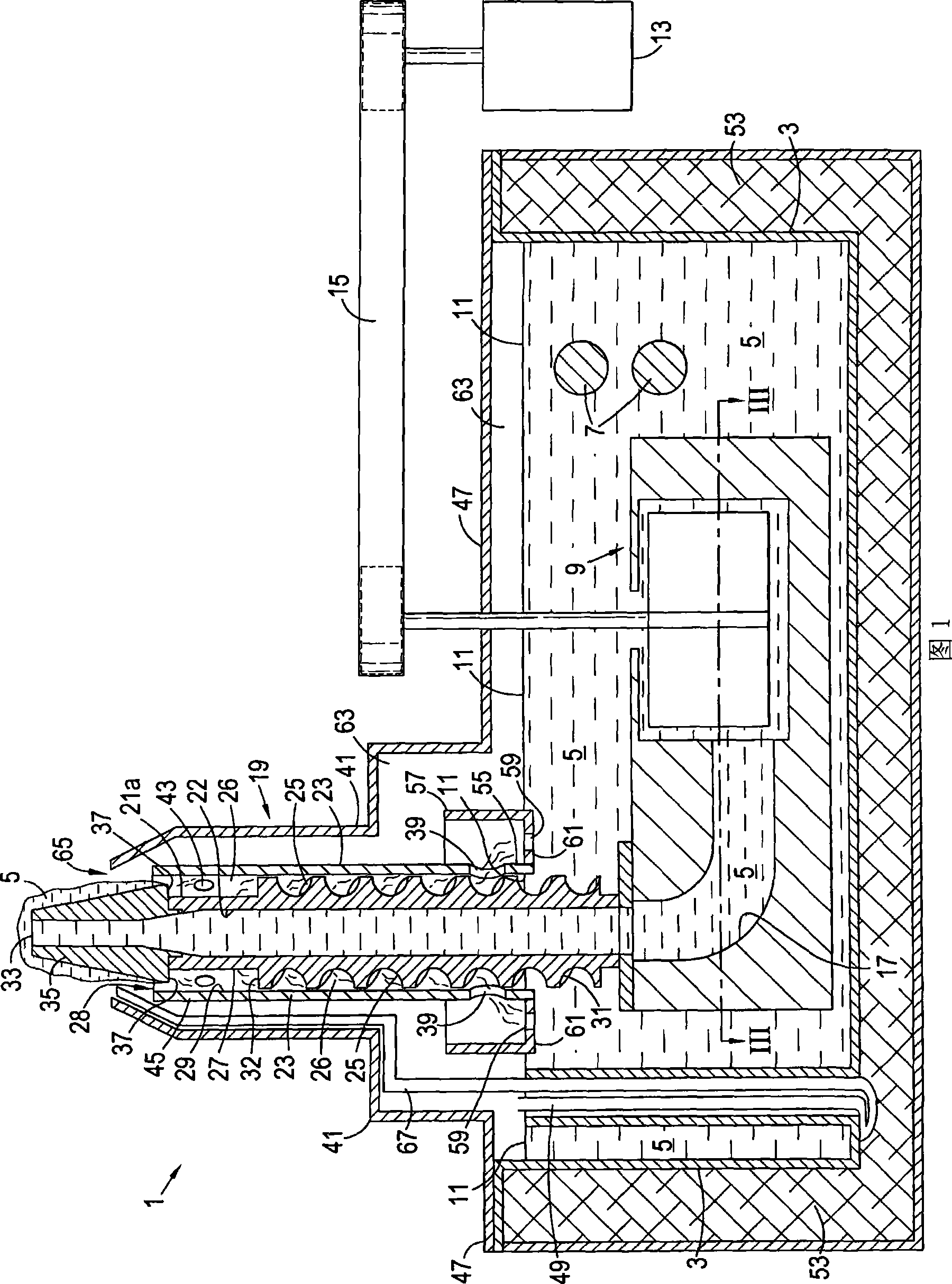

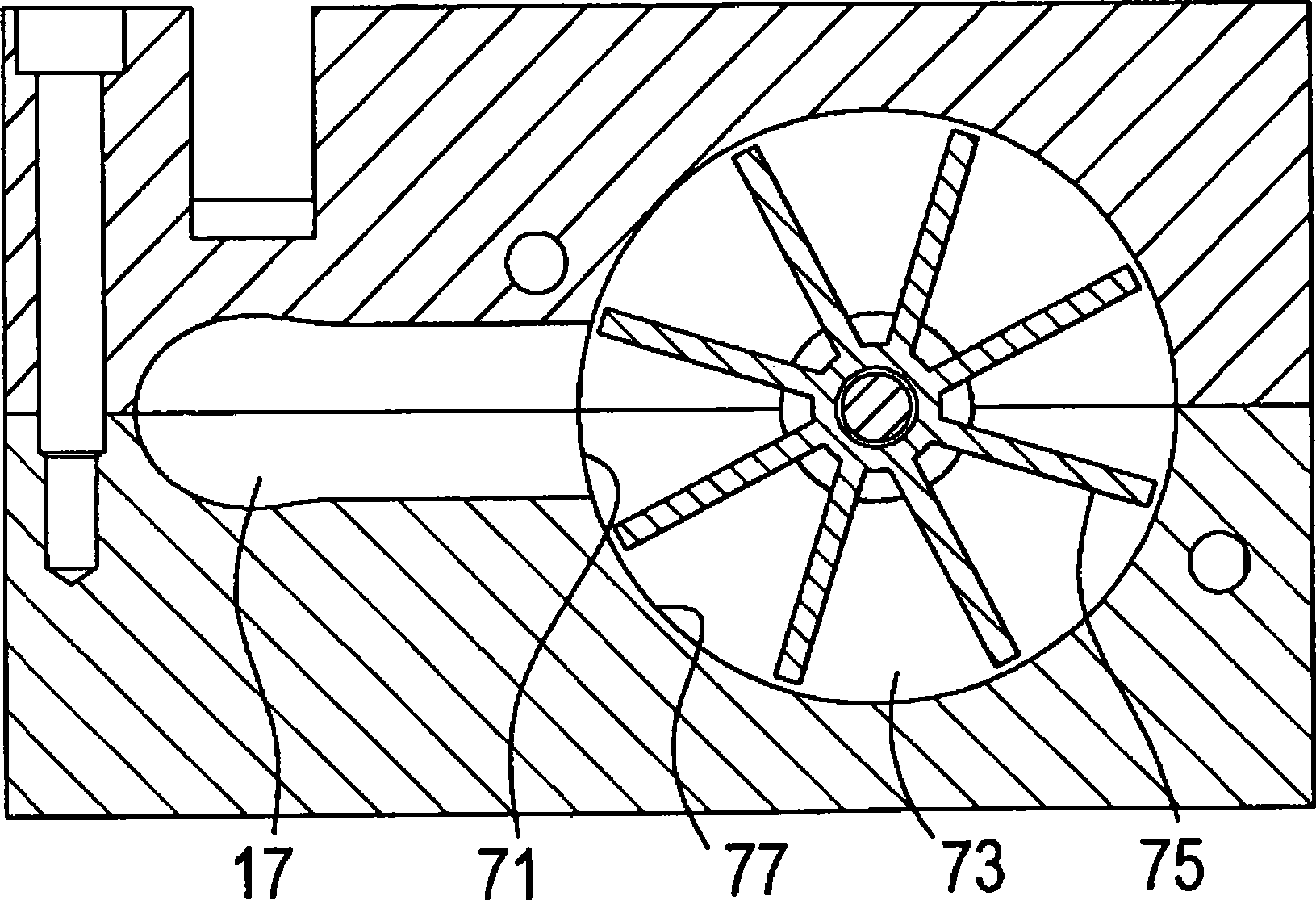

[0015] Referring to FIG. 1 , a selective soldering device 1 includes a chamber 3 for containing molten solder 5 . The solder 5 is heated by the electric heater 7 . The impeller pump 9 is accommodated in the solder chamber 3 below the upper surface 11 of the solder 5 and is driven by an electric motor 13 via a traction belt 15 . The pump 9 sucks the molten solder through the conduit 17 to the nozzle 19 .

[0016] Nozzle 19 includes a nozzle body 21 having an inner bore 22 in fluid communication with conduit 17 . The nozzle body 21 is surrounded by a sleeve 23 extending down to the solder surface 11 . Formed on an outer surface 27 of the nozzle body 21 is a helical passage 25 in a space 26 between the nozzle body 21 and the sleeve 23 . This space is open at its upper end 28 . It should be understood that the channel 25 may be formed on the inner surface 29 of the sleeve 23, or provided as a separate unit. The lower end 31 of the helical channel 25 extends down to the solder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com