Full-automatic control selective wave soldering device and method

A wave soldering and selective technology, which is applied in the direction of welding equipment, auxiliary equipment, tin feeding equipment, etc., can solve the problems of high temperature of preheating mechanism and poor guarantee of spraying pressure of spray valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

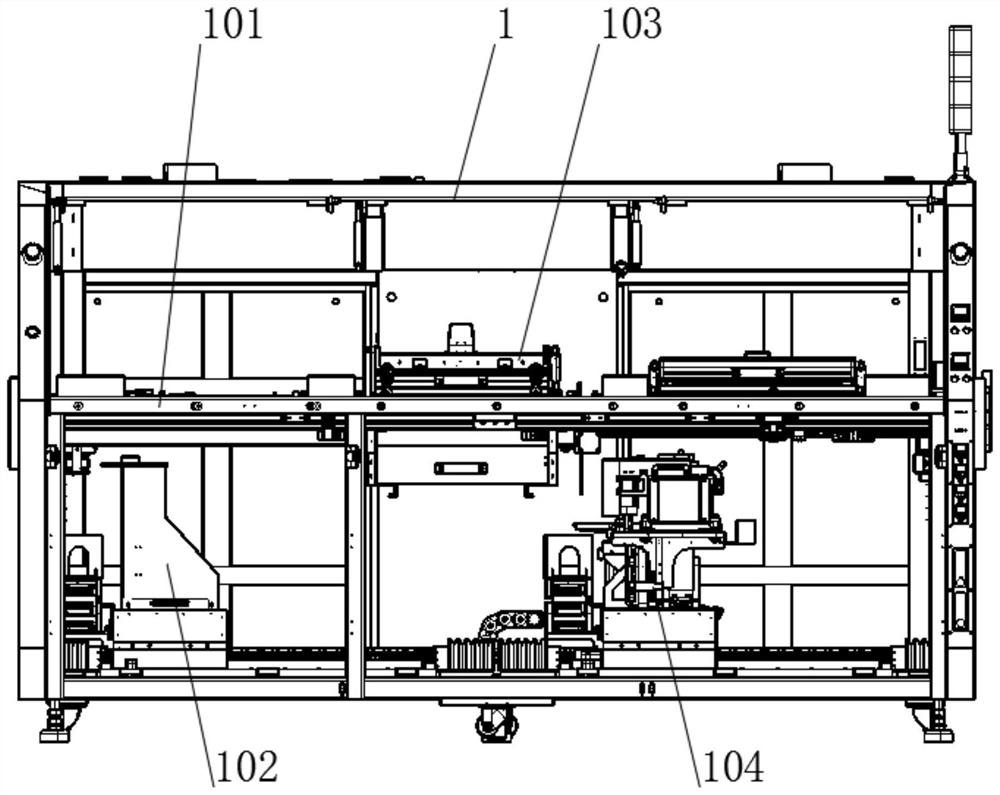

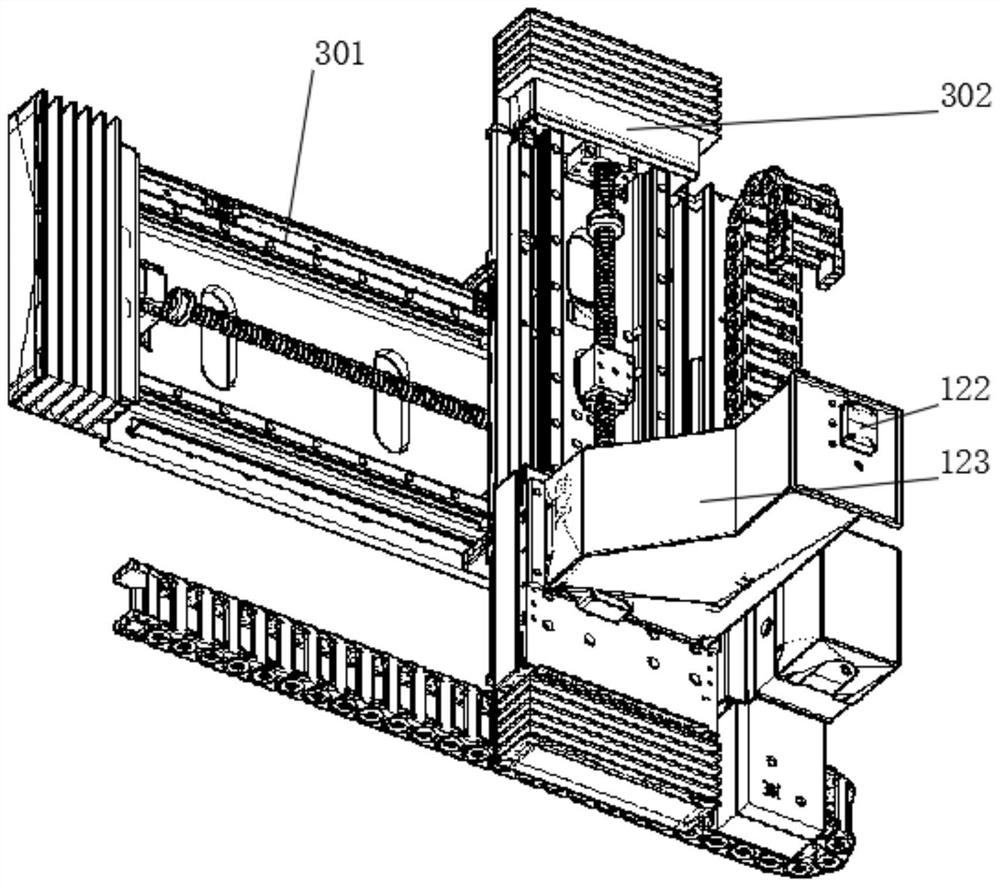

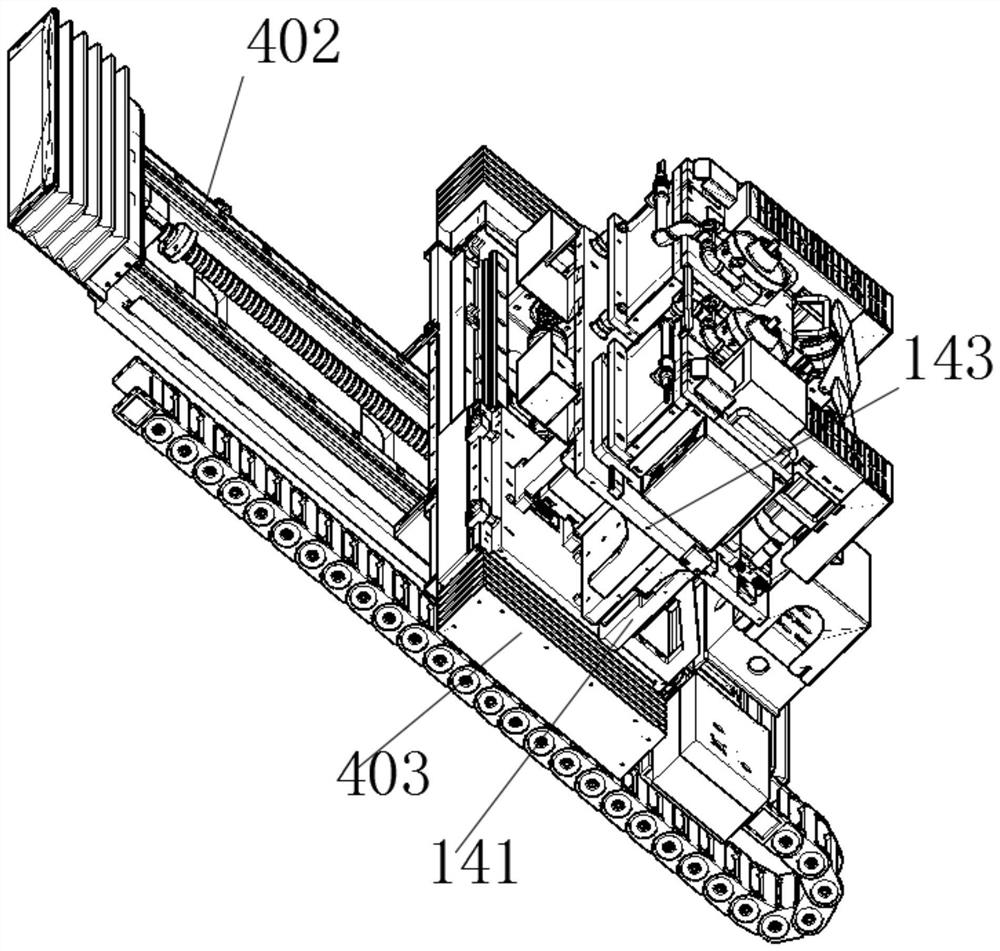

[0040] see Figure 1 to Figure 11, the present invention provides a technical solution: a device for fully automatic control of selective wave soldering, which is characterized in that it includes a main body 1 and a controller arranged inside the main body 1, a transport guide rail 101, a flux spraying mechanism 102, a double-layer Preheating mechanism 103 and selective welding mechanism 104, the controller includes: transportation controller, spraying controller, preheating controller and welding controller, spraying controller includes pressure controller, pressure sensor, flow meter and pressure reducing valve , the pressure controller is connected with the pressure sensor, the flow meter and the pressure reducing valve, the pressure sensor is installed on the spray valve 122, the flow meter and the pressure reducing valve are installed on the spray pipe at the bottom of the spray valve 122, the preheating controller includes a temperature control chip and a plurality of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com