Reciprocating type printed circuit board (PCB) selective crest welder

A wave soldering machine, selective technology, applied in welding equipment, auxiliary devices, metal processing and other directions, can solve the problems affecting the placement of components, and achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

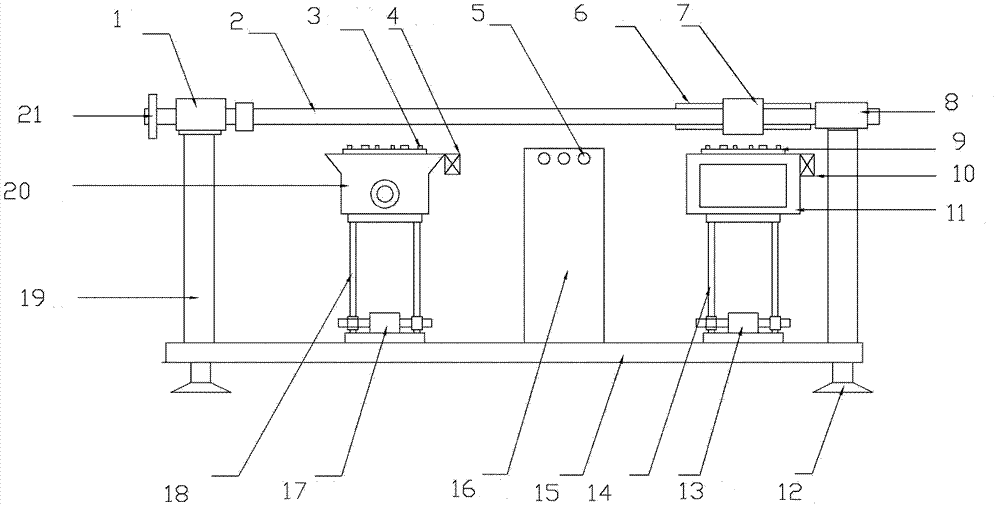

[0016] The structural principle and working principle of the present invention will be further described below in conjunction with the drawings and specific embodiments.

[0017] As shown in the accompanying drawings, a reciprocating PCB selective wave soldering machine of the present invention includes a selective flux spraying assembly, a preheating heating assembly, a selective soldering assembly and a delivery positioning assembly, and the selective flux spraying assembly includes Foam box elevating rod 18, drive the motor B17 of foaming case elevating rod 18 lifting, the foaming case 20 that is arranged on foaming case elevating rod 18 top and the foam template 3 that is placed on foaming case 20 tops; Thermal heating assembly comprises heating box 16 and is arranged on the infrared heating tube 5 of heating box 16 tops, and described selective soldering assembly comprises tin furnace elevating rod 14, drives the motor A 13 of tin furnace elevating rod 14 lifting, is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com