Method for predicting structure evolution of austenite dynamic recrystallization in thermal deformation of plate-strip steel

A technology of recrystallized structure and hot deformation, applied in the field of steel rolling, to achieve the effect of speeding up the development cycle and saving the experimental cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

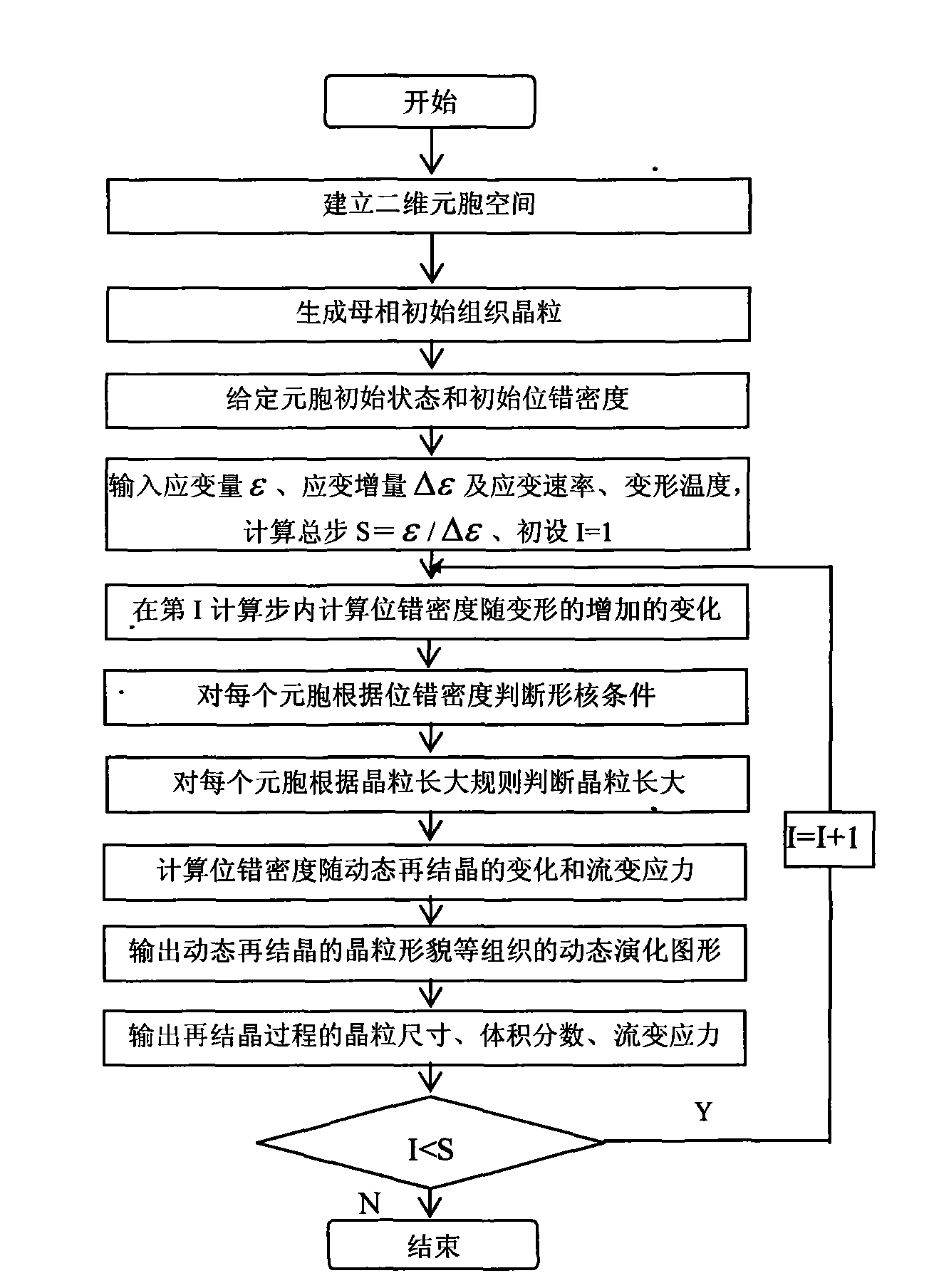

[0047] like figure 1 As shown, the specific calculation and analysis steps of the method for predicting the evolution of austenite dynamic recrystallization structure in hot deformation of plate and strip steel of the present invention are as follows:

[0048] 1. Start;

[0049] 2. Establish a two-dimensional cell space;

[0050] 3. Generate the initial grain of the parent phase;

[0051] 4. Given the initial state and initial dislocation density of the cell;

[0052] 5. Input the strain amount ε, strain increment Δε, strain rate, and deformation temperature, calculate the total step S=ε / Δε, and initially set I=1;

[0053] 6. Calculate the change of dislocation density with the increase of deformation in the first calculation step;

[0054] 7. For each cell, judge the nucleation condition according to the dislocation density;

[0055] 8. For each cell, judge the grain growth according to the grain growth rule;

[0056] 9. Calculate the change of dislocation density with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com