Device and method for selective soldering

A selective, solder technology, used in tin feeding devices, welding equipment, assembling printed circuits with electrical components, etc., can solve problems such as the increase in the error rate of metal scrap, reduce pollution and error rates, improve efficiency, and improve welding quality. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

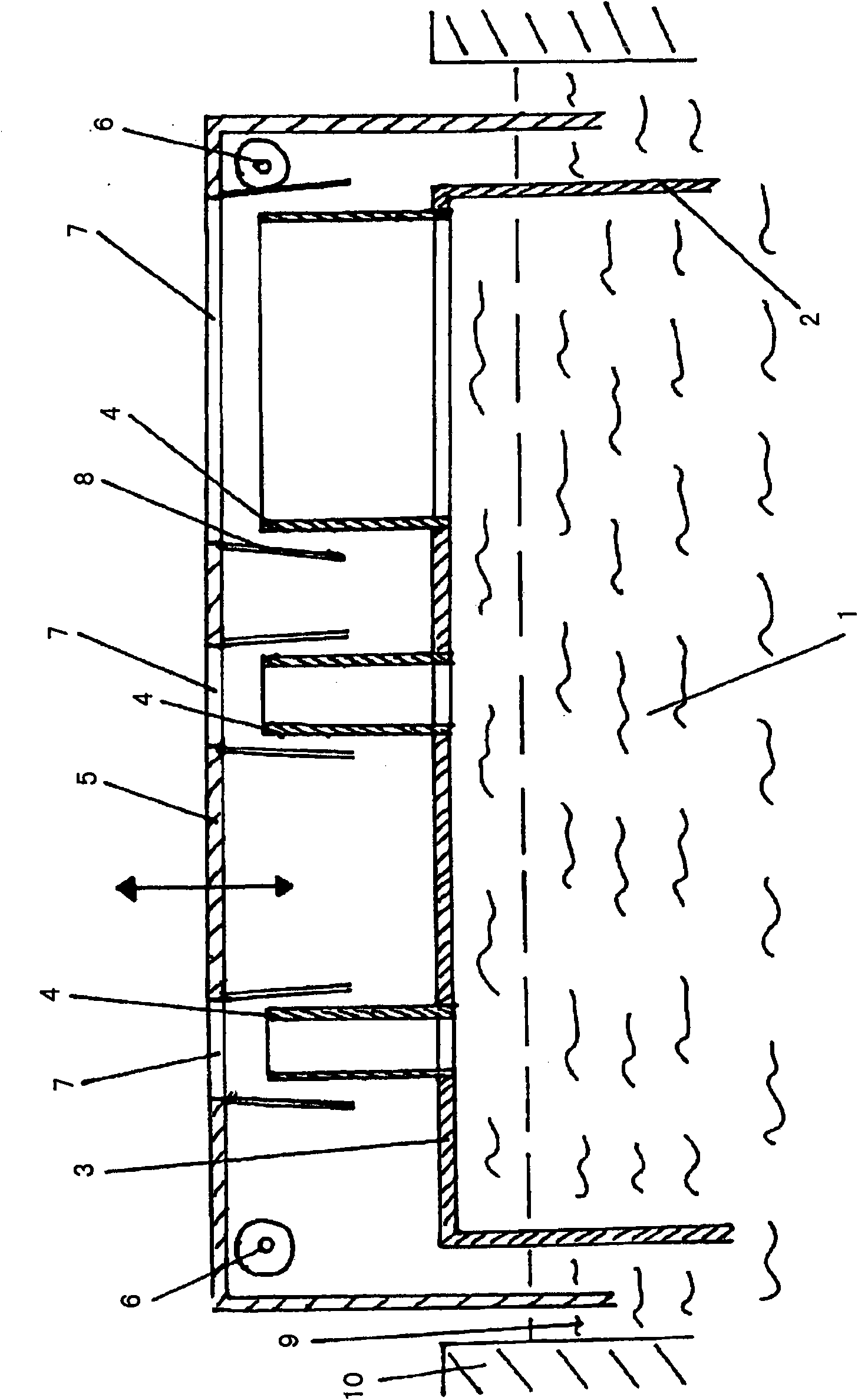

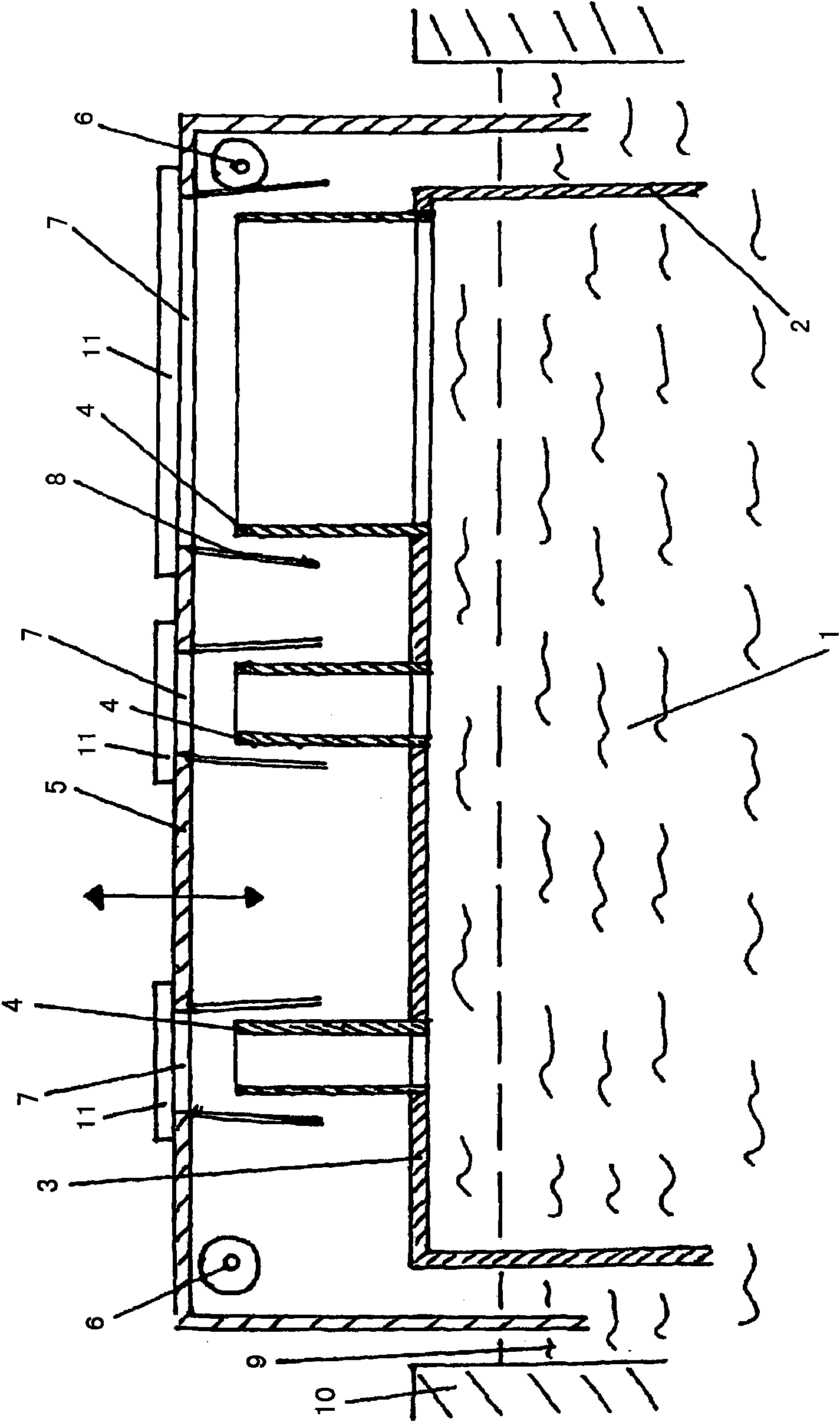

[0031] figure 1 A container 10 for liquid solder is shown, which contains a so-called solder bath 9 with solder channels 2 . The drawing further shows three nozzles 4 mounted on the solder channel 2 . In this example, the solder channel 2 is generally embodied as a pressure channel and is closed to the surrounding environment. Solder channel 2 on figure 2 Only part of it is drawn.

[0032] The nozzle 4 is mounted on the solder channel 2 in the region of the cover sheet 3 and is secured by said solder channel 2 . In order to pressurize the liquid solder 1, a structure of a solder pump (not shown) is provided. The solder channel 2 is surrounded by a vertically movable cover 5 which is immersed in the solder bath 9 or otherwise sealed to the surface of the solder bath 9 . A channel 7 for each nozzle 4 is provided in the cover 5 . Furthermore, in this example two protective gas delivery devices 6 are provided, which achieve the purpose of delivering the protective gas under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com