Eutectic chip soldering method

A eutectic welding and chip technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as scratches on the aluminum layer, great influence on welding quality, and failure to meet the surface quality of chips, etc., to achieve guaranteed Surface quality, the effect of simplifying the welding operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

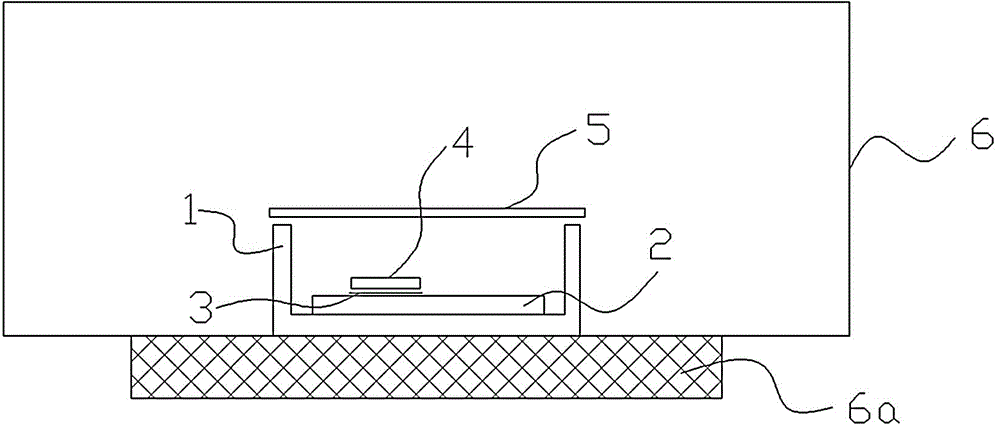

[0017] like figure 1 As shown, the present invention provides a chip eutectic welding method, comprising the following steps:

[0018] a) Clean the welding piece 3 and the part to be welded 2 (such as a ceramic substrate), remove the dirt on the surface of the welding piece 3 and the part to be welded 2, and perform surface grinding and ultrasonic cleaning on the welding piece 3 and the part to be welded 2 to achieve removal the purpose of defilement;

[0019] b) Cutting the welding piece 3 so that the size of the welding piece 3 is compatible with the chip 4, and performing a leveling operation on the welding piece 3, the area of the welding piece 3 should be slightly larger than the area of the chip 4;

[0020] c) placing the part to be welded 2 horizontally on the bottom of the metal container 1;

[0021] d) Put the welding piece 3 horizontally on the welding area of the piece to be welded 2, and then place the chip 4 horizontally on the center of the welding piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com