Demountable support device and assembling method thereof

A technology of a bracket device and a connecting device, which is applied in the direction of construction and building structure, can solve the problems of time-consuming and laborious, increase construction costs, safety accidents, etc., and achieve the effects of reducing engineering costs, improving construction quality, and shortening construction periods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

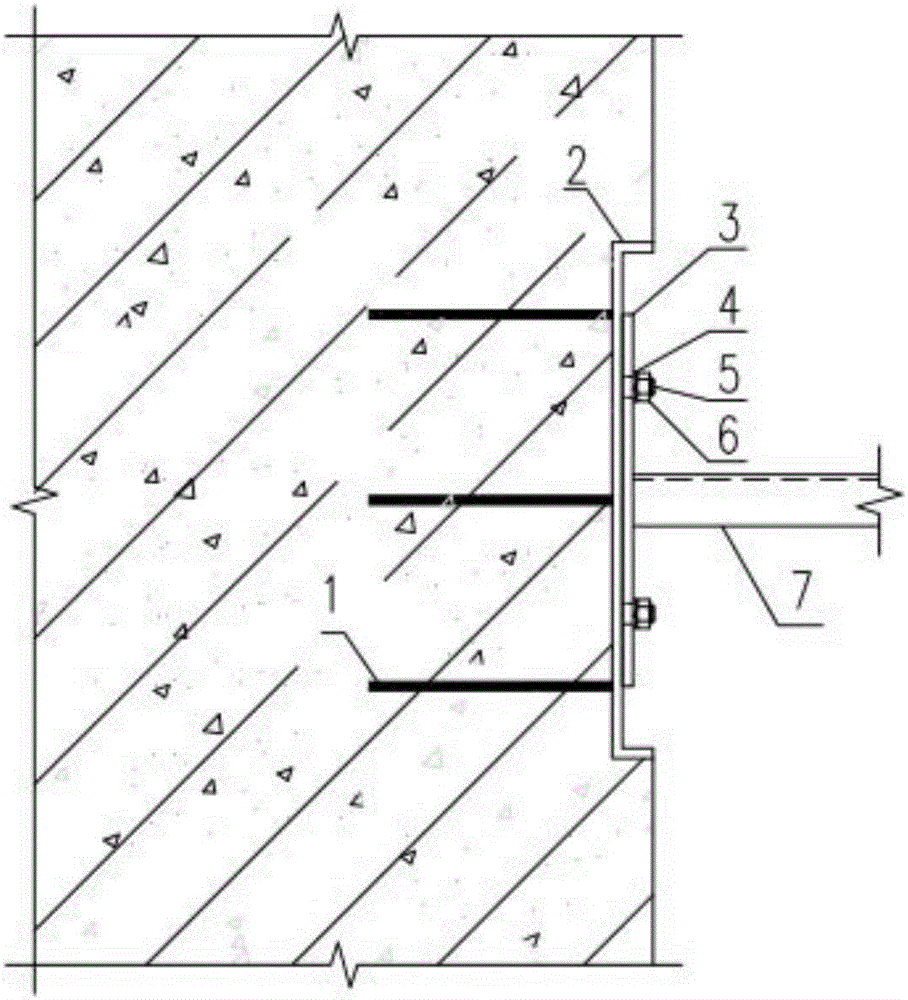

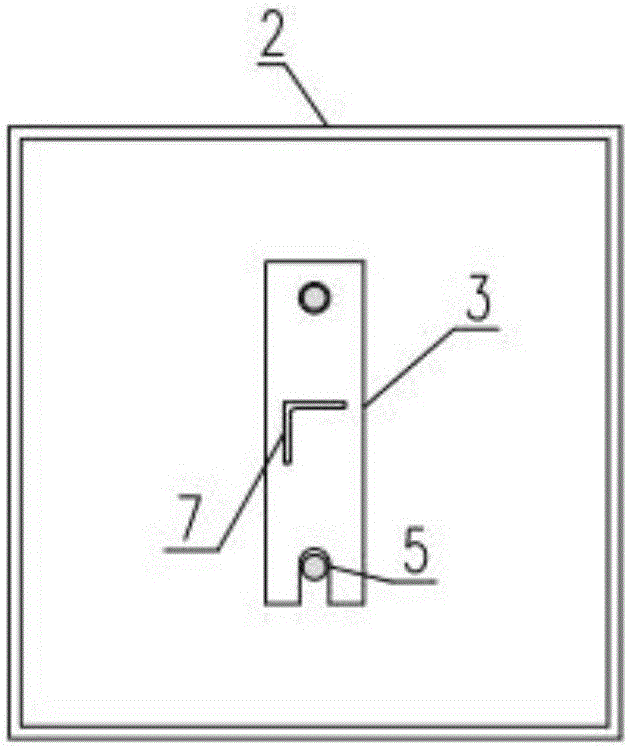

[0026] A detachable bracket device of the present invention, it comprises embedded part, bracket 7, connecting device; Embedded part comprises anchor fluke 1, concave steel plate 2, anchor fluke 1 is welded on the back side of concave steel plate 2, bracket 7 It is connected to the concave surface of the concave steel plate 2 through the connecting device.

[0027] The bracket and the embedded parts in the present invention are mechanically connected, so they can be installed and disassembled conveniently.

Embodiment 2

[0029] The connecting device includes a connecting plate 3 and several connecting units; the bracket 7 is fixed on the connecting plate 3, and the connecting plate 3 is connected to the concave surface of the concave steel plate 2 through the connecting units.

Embodiment 3

[0031] There are at least two connecting units; each connecting unit is divided into fixed and movable parts, the fixed part is arranged in the concave steel plate 2, and the movable part is connected with the fixed part through the hole on the connecting plate 3; the connecting plate The two holes on the 3 are located at the upper and lower positions of the support 7 respectively.

[0032] The specific number of connection units is determined according to the force requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com