Stator-plate assembly, motor and method for manufacturing motor

A technology for stator laminations and electric motors, which is used in the manufacture of electric motors, especially in the field of electric motors, clutches and/or transmission housings, which can solve the problems of high design or installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

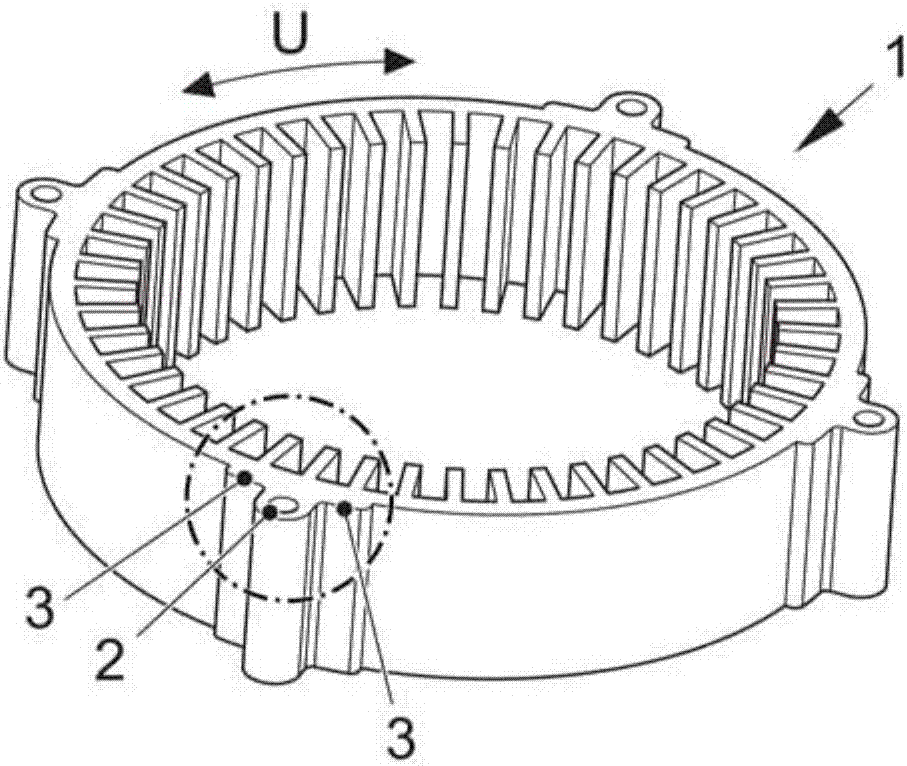

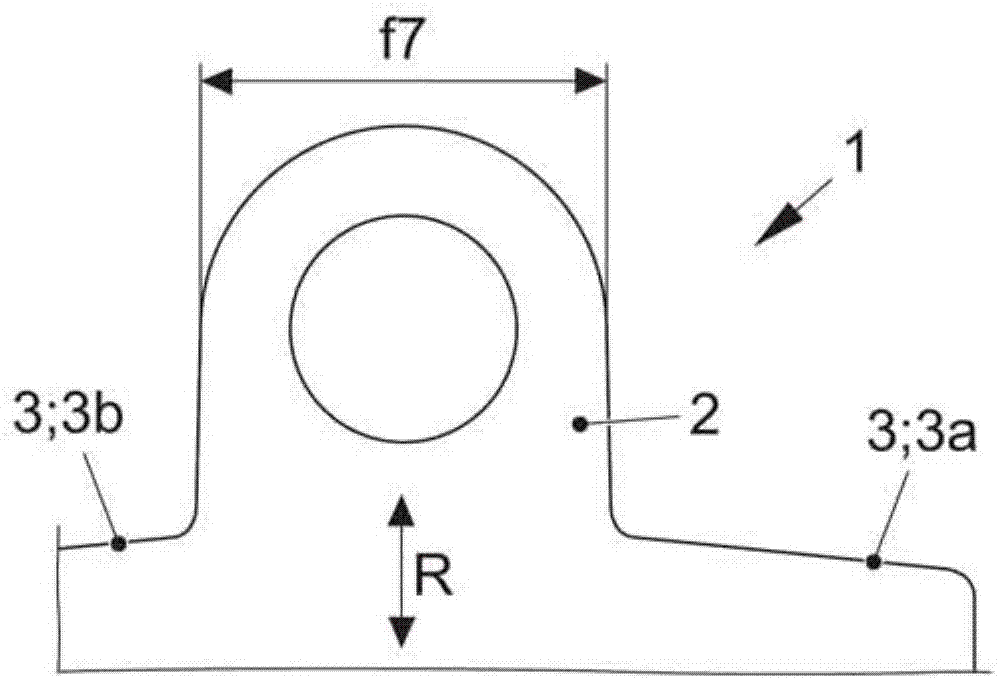

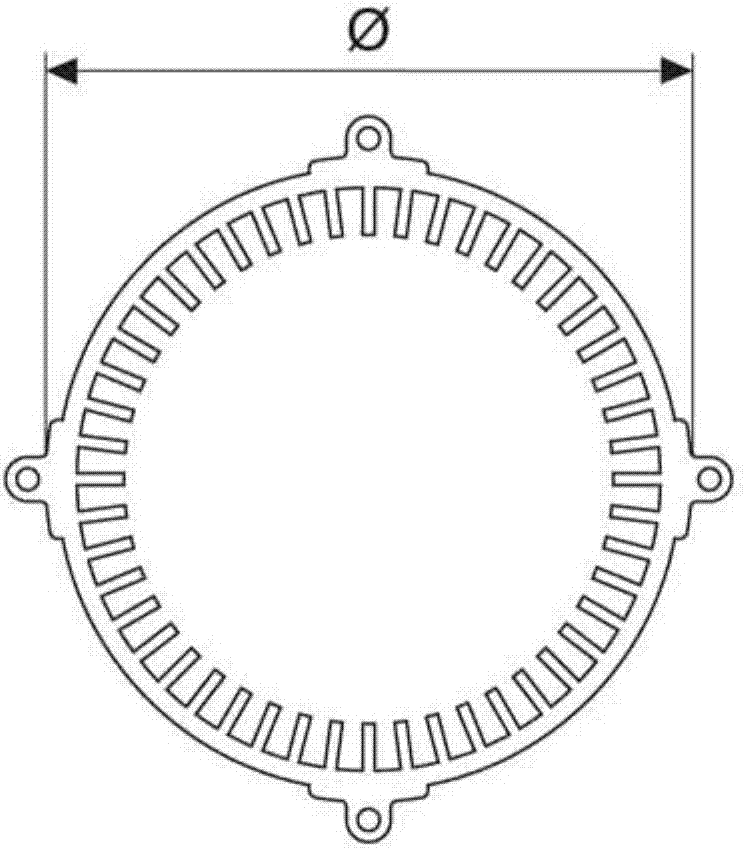

[0032] figure 1 A preferred embodiment of a laminated stator pack 1 according to the invention for an electric machine, for example for an electric motor, in particular a motor vehicle, is shown, wherein the laminated stator pack 1 is designed to be arranged on a housing 10, in particular a clutch and / or In the transmission housing or can be arranged therein. figure 1It is shown that the stator lamination stack 1 has a plurality of, in particular four, circumferential form-fit elements 2 in its outer peripheral region for forming a gap along the stator lamination stack 1 between the stator lamination stack 1 and the housing 10 . Circumferential form-fit connection. A particularly defined angular position or angular orientation between the stator lamination core 1 and the housing 10 can be achieved during assembly by means of the circumferential form-fit element 2 .

[0033] figure 1 It is also shown that the stator lamination stack 1 also has a plurality, in particular four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com