Ceramic electronic component and manufacturing method thereof

A technology of electronic components and manufacturing methods, applied to printed circuit components, fixed capacitor components, transformer/inductor components, etc., can solve the problems of reduced reliability, increased and reduced water absorption, and reduce the dielectric Constant, enhanced tensile strength, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

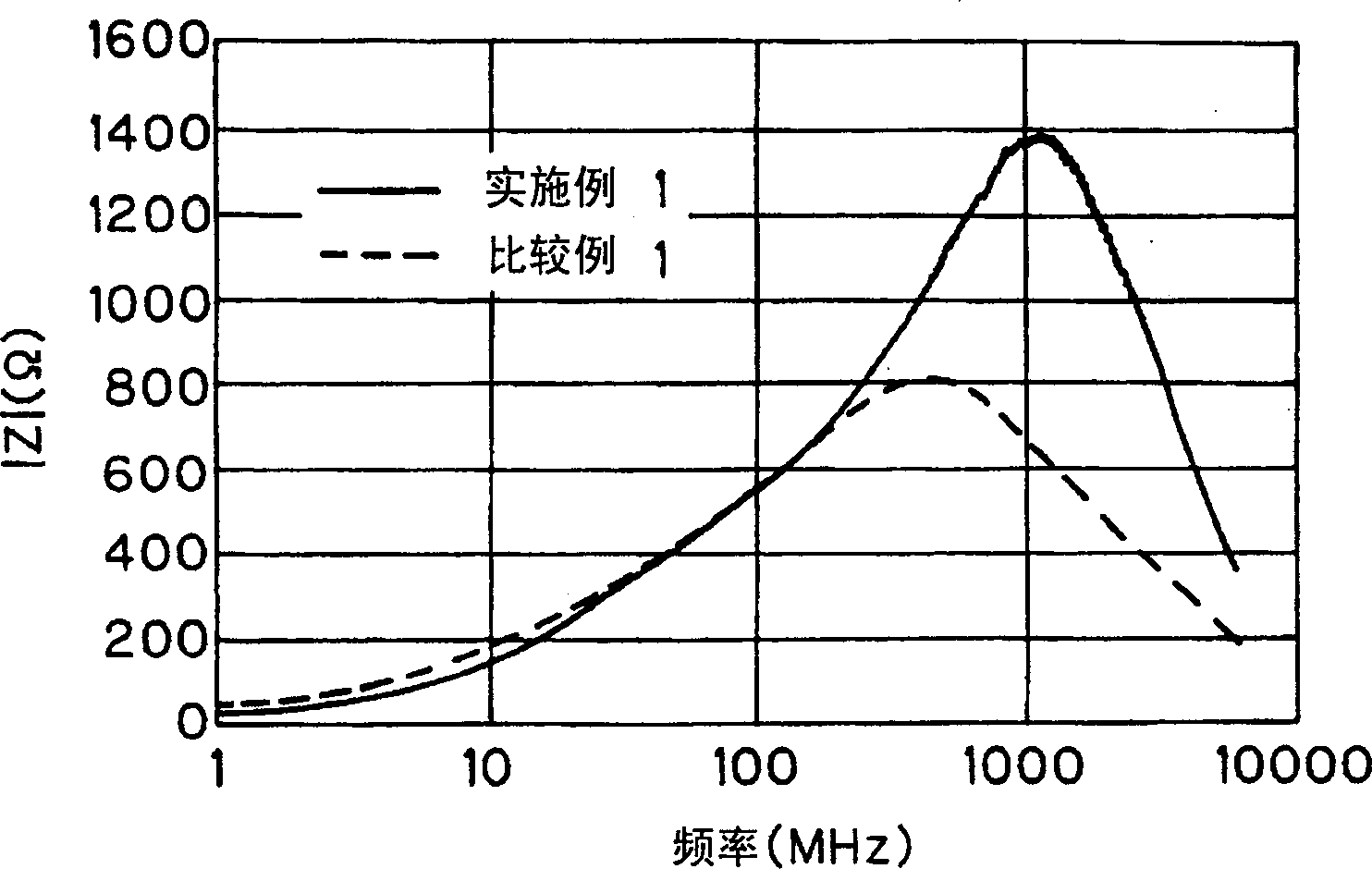

[0066] Embodiment 1 Production of ceramic sintered body with pores

[0067] In Embodiment 1, a method for forming a ceramic sintered body having pores will be described.

[0068] (1) First, in order to obtain a NiZnCu ferrite material having a magnetic permeability μ of 400, oxide raw materials of nickel, zinc, and copper were mixed and fired at 800° C. for 1 hour.

[0069] (2) Then, it was pulverized by a ball mushroom machine and dried to obtain a ferrite raw material (oxide mixed powder) having an average particle diameter of about 2 μm.

[0070] (3) Then, to the ferrite raw material obtained, commercially available spherical polymers were added in various proportions as shown in Table 1 [this embodiment 1 is a spherical burnt material composed of cross-linked polystyrene (average particle diameter = 8 μm, trade name: TECHPOLYMER, manufactured by Sekisui Plastics Co., Ltd. (SEKISUI PLASTICS CO., LTD.) Add solvent, binder, and dispersant to mix, manufacture and prepare cer...

Embodiment approach 2

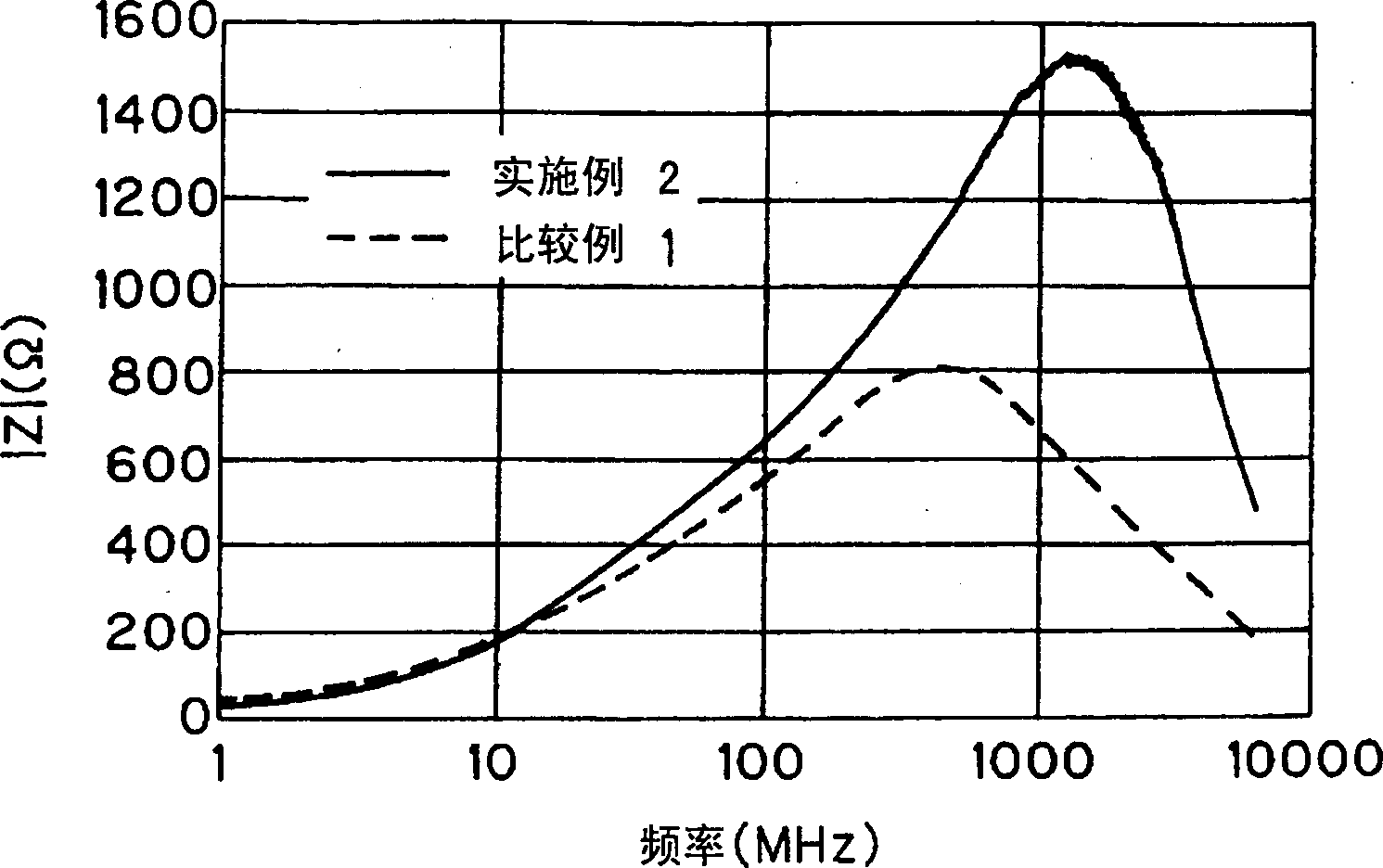

[0096] Embodiment 2 Production of ceramic sintered body with pores

[0097] (1) As in the above-mentioned Embodiment 1, the pore ratio was adjusted by changing the amount of the mixed organic material, and the same ceramic sintered body as obtained in (5) of of Embodiment 1 was produced.

[0098] (2) Next, an epoxy resin having a dielectric constant of 3.4 was impregnated into the pores of the ceramic sintered body, and heated to 150° C. to cure the epoxy resin.

[0099] In this way, the dielectric constant, magnetic permeability, flexural strength, and water absorption of the ceramic sintered body filled with resin in the pores were measured. The results are shown in Table 2.

[0100] sample

serial number

spherical poly

Heping

Average particle size

(μm)

(μm)

Rate

(%)

fill the void with glass

water absorption

(%)

Spend

(MPa...

Embodiment approach 3

[0118] (1) A porous ferrite (ceramic sintered body) having a porosity of 60 vol % was fabricated by the same method as in the first and second embodiments described above.

[0119] (2) Then, impregnate the porous ferrite in a solution that dilutes an epoxy resin with a dielectric constant of 3.4 to a viscosity of 300mPa·s and 500mPa·s with an organic solvent, and then heat it at 150°C for 30 minutes to cure epoxy resin.

[0120] Then, the porosity, dielectric constant, and flexural strength of the epoxy resin-impregnated and cured porous ferrite thus obtained were measured.

[0121]For impregnating a solvent-free epoxy resin with a dielectric constant of 8.4 and a viscosity of 5000mpa·s and curing the same sample, measure the porosity, dielectric constant and flexural strength. The results are shown in Table 3.

[0122] Filler

(vol%)

Dielectric constant

(MPa)

before filling

60

6.6

20

Fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com