Heat-resistant high-temperature vulcanized silicone rubber and preparation method thereof

A high-temperature vulcanization and high-temperature-resistant technology, which is applied in the field of silicone rubber compounds, can solve the problems of low comprehensive performance of rubber compounds, and achieve the effects of easy universal production and promotion, easy availability of raw materials, and low aging attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

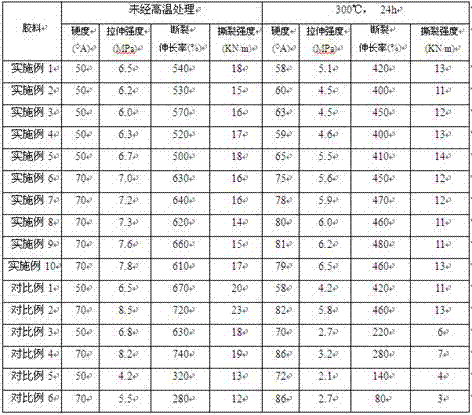

Examples

Embodiment 1

[0026] Take 100 parts of raw rubber, 4 parts of hydroxy silicone oil, 0.4 parts of stearic acid, 2 parts of vinylmethyldimethoxysilane, 20 parts of specific surface area of 150m 2 / g of white carbon black, after mixing evenly, heat treatment at 150°C for 30 minutes, add 5 parts of nano-sized iron oxide, 15 parts of micron-sized iron hydroxide, 2 parts of methylphenyl silicone resin, 1 part of diphenyl silicon Diol, after mixing evenly, heat treatment at 200°C for 40 minutes, vacuum for 1 hour, remove low molecular weight, and cool to discharge.

Embodiment 2

[0028] The previous steps are the same as in Example 1. After heat treatment, add 5 parts of nanoscale iron oxide, 10 parts of micron iron hydroxide, 2 parts of phenyl MQ silicone resin, and 1 part of phenyltriethoxysilane. After banburying evenly, heat treatment at 150°C 40min, vacuum 1h, remove low molecular weight, cool and discharge.

Embodiment 3

[0030] The previous steps are the same as in Example 1. After heat treatment, add 5 parts of nano-sized cerium oxide, 15 parts of micron-sized silicon powder, 2 parts of phenyl MQ silicone resin, and 1 part of phenyltriethoxysilane. After banburying evenly, heat treatment at 150°C 40min, vacuum 1h, remove low molecular weight, cool and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com