High thermal conductive and insulating polymer composite and preparing method and application thereof

A technology of insulating polymers and composite materials, applied in the field of preparation of polymer composite materials, can solve the problems of limited application, difficult collection of products, difficult control, etc., and achieve the effect of ensuring mechanical strength, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

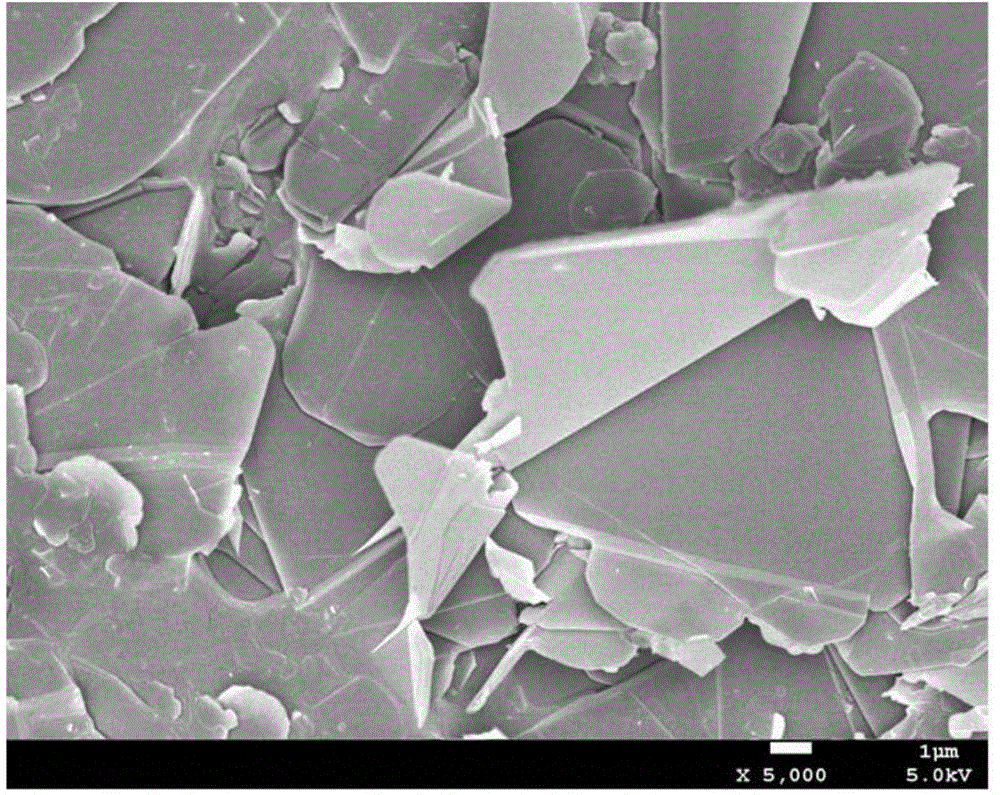

[0040] 1) Preparation of hexagonal boron nitride nanosheets

[0041] (1) Stir and mix 1 g of hexagonal boron nitride and 500 ml of isopropanol, and perform ultrasonic treatment in an ultrasonic cleaning machine with a power of 200 w in the isopropanol solution for 6 hours to obtain a mixed solution.

[0042] (2) The above mixture was left to stand for 48 hours under natural conditions, filtered to remove isopropanol, washed with acetone for 3 times, and treated in a vacuum oven at a temperature of 90° C. for 9 hours to collect high-yield hexagonal boron nitride nanosheets.

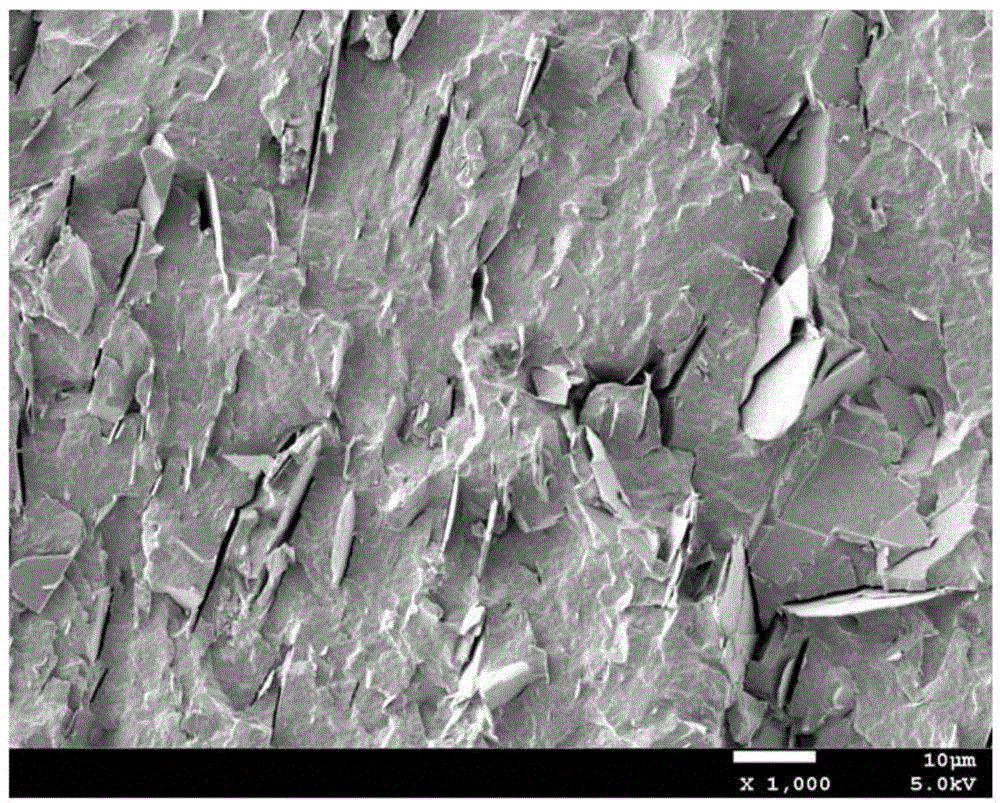

[0043] 2) Preparation of high thermal conductivity insulating polymer composites

[0044] 640g of nylon and 60g of nano-boron nitride treated above were added and mixed in a high-speed mixer for 5 minutes. At a rotation speed of 30rpm and a temperature of 240°C, they were extruded by twin-screws to obtain high thermal conductivity and insulation nylon 6 composite materials.

Embodiment 2

[0046] 1) Preparation of hexagonal boron nitride nanosheets

[0047] (1) Stir and mix 0.1 g of hexagonal boron nitride and 50 ml of isopropanol, and ultrasonically treat at 100w for 4 hours in the isopropanol solution to obtain a mixed solution.

[0048] (2) The mixture was left to stand for 24 hours under natural conditions, filtered to remove isopropanol, washed twice with acetone, and treated in a vacuum oven at a temperature of 50° C. for 5 hours to collect boron nitride nanosheets with a high yield.

[0049] 2) Preparation of high thermal conductivity insulating polymer composites

[0050] 660g of nylon and 40g of the above-mentioned nano-boron nitride were added and mixed in a high-speed mixer for 5 minutes. At a speed of 30rpm and a temperature of 260°C, they were extruded by a single screw to obtain a high thermal conductivity and insulation nylon 66 composite material.

Embodiment 3

[0052] 1) Preparation of hexagonal boron nitride nanosheets

[0053](1) Stir and mix 10 g of hexagonal boron nitride, 500 ml of isopropanol and 500 ml of aqueous solution containing 0.5% sodium lauryl sulfate, and ultrasonically treat at 1000w for 72 hours in the isopropanol solution to obtain a mixed solution.

[0054] (2) The mixture was left to stand for 72 hours under natural conditions, filtered to remove isopropanol, washed 5 times with acetone, and treated in a vacuum oven at 120° C. for 10 hours to collect boron nitride nanosheets with high yield.

[0055] 2) Preparation of high thermal conductivity insulating polymer composites

[0056] Mix 90g of polycarbonate with 10g of nano-boron nitride treated above in a mixer for 10min, extrude with a micro-screw at a speed of 60rpm and a temperature of 270°C to obtain a polycarbonate composite material with high thermal conductivity and insulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com