Super-flexible sulphoaluminate cement-based 3D printing material

A sulfoaluminate cement and 3D printing technology, applied in the field of building materials, can solve the problems of poor toughness and high strength, and achieve the effects of improving flexibility, ensuring mechanical strength, good flexibility and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

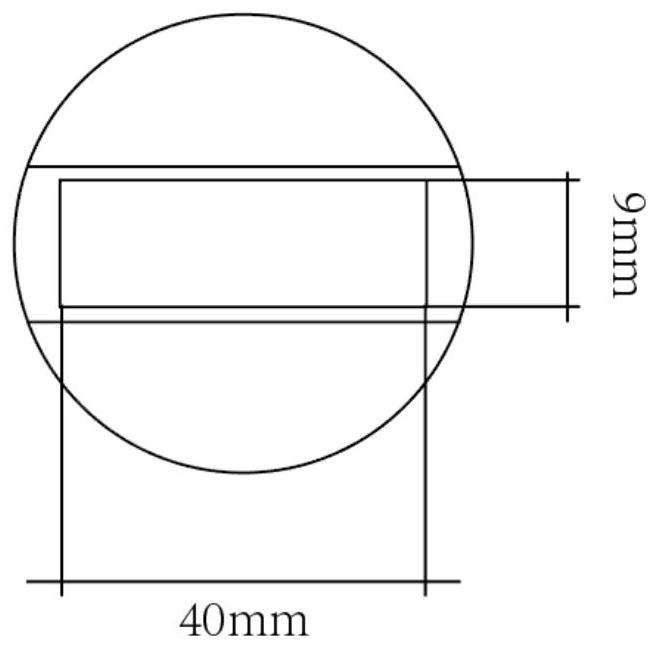

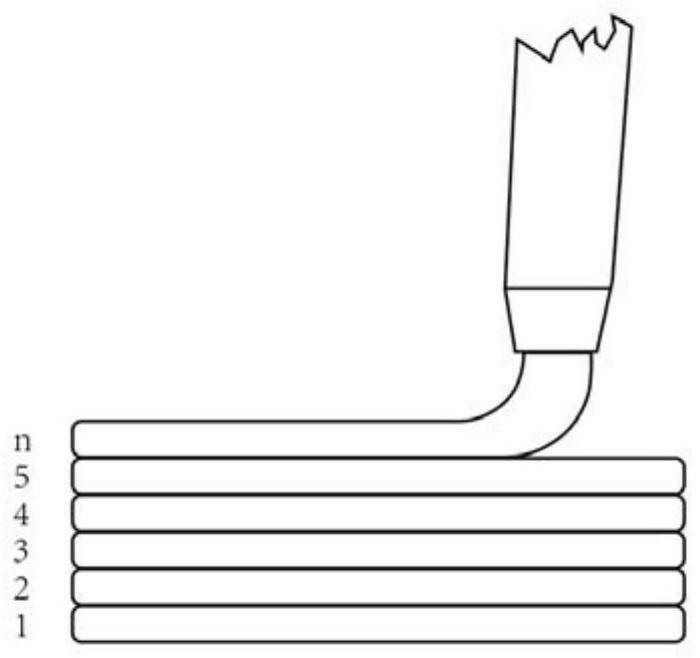

Image

Examples

Embodiment 1

[0032] An ultra-flexible sulfoaluminate cement-based 3D printing material. The raw materials include the following materials in parts by weight: 850 parts of cement, 4 parts of water reducing agent, 0.4 part of thickener Wenlun glue, 150 parts of redispersible latex powder, 2 parts of defoamer, 1 part of thickener cellulose ether, 1 part of coagulant.

[0033] The specific preparation method is as follows: weigh the above-mentioned raw material powder prepared according to the proportion, and fully mix other raw materials except water; according to the set water-cement ratio 0.34, weigh the water consumption in the mix ratio, and then mix the powder Pour the material and water into the mixing container. The mixing procedure is as follows: first stir slowly for 30 seconds, then stir quickly for 3-4 minutes, and mix evenly. The resulting slurry is the ultra-flexible sulfoaluminate cement-based 3D printing material.

[0034] The initial setting and final setting times of the abov...

Embodiment 2

[0039] An ultra-flexible sulfoaluminate cement-based 3D printing material. The raw materials include the following materials in parts by weight: 750 parts of cement, 4 parts of water reducing agent, 0.5 part of thickener Wenlun glue, 250 parts of redispersible latex powder, 2 parts of defoamer, 2 parts of thickener cellulose ether, 2 parts of coagulant.

[0040] The water-cement ratio was 0.36, and the corresponding slurry was prepared by the same method as in Example 1. The measured maximum deformation was 7.2%, and the initial setting and final setting times were 34 minutes and 45 minutes, respectively. Its 1d flexural and compressive strengths were 5.8MPa and 13.7MPa respectively, 3d flexural and compressive strengths reached 7.5MPa and 15.2MPa respectively, and 7d flexural and compressive strengths reached 8.0MPa and 17.9MPa respectively. 55%. The test results show that the ultra-flexible sulfoaluminate cement-based 3D printing material (slurry) prepared in Example 2 has ...

Embodiment 3

[0042] An ultra-flexible sulfoaluminate cement-based 3D printing material. The raw materials include the following materials in parts by weight: 750 parts of cement, 4 parts of water reducing agent, 0.5 part of thickener Wenlun glue, water-based polyurethane emulsion (using Xinletian brand Water-based polyurethane waterproof coating) 200 parts, defoamer 2 parts, thickener cellulose ether 3 parts, coagulant 4 parts.

[0043] The water-cement ratio was 0.33, and the corresponding product was prepared in the same manner as in Example 1. The maximum deformation measured was 5.5%, and the initial setting and final setting times were 36 minutes and 45 minutes respectively. Its 1d flexural and compressive strengths are 5.5MPa and 13.2MPa respectively, 3d flexural and compressive strengths reach 7.2MPa and 15.6MPa respectively, and 7d flexural and compressive strengths reach 8.3MPa and 17.7MPa respectively. 60%. The test results show that the ultra-flexible sulfoaluminate cement-base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com