Removed material collecting and dust removing system during drilling process of carbon fiber composite material

A composite material, dust removal system technology, applied in the direction of removing smoke and dust, dispersing particle filtration, metal processing, etc., can solve problems such as destructive influence of machine tool equipment and operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

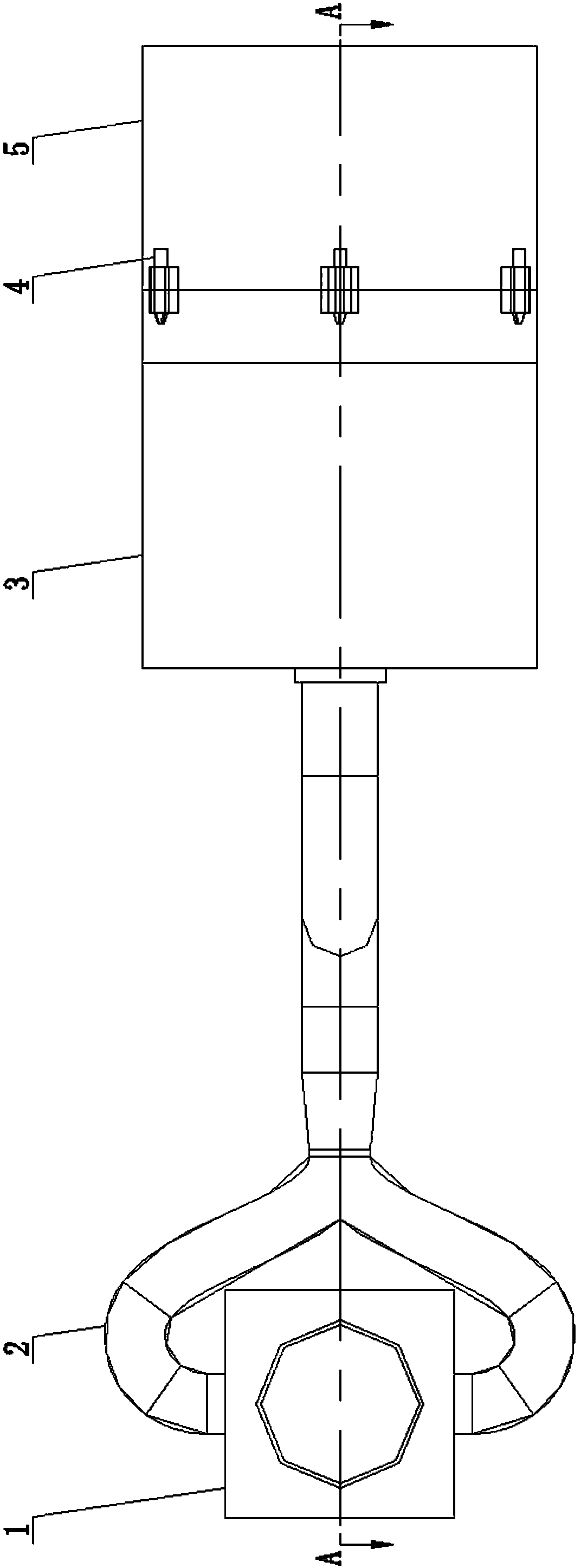

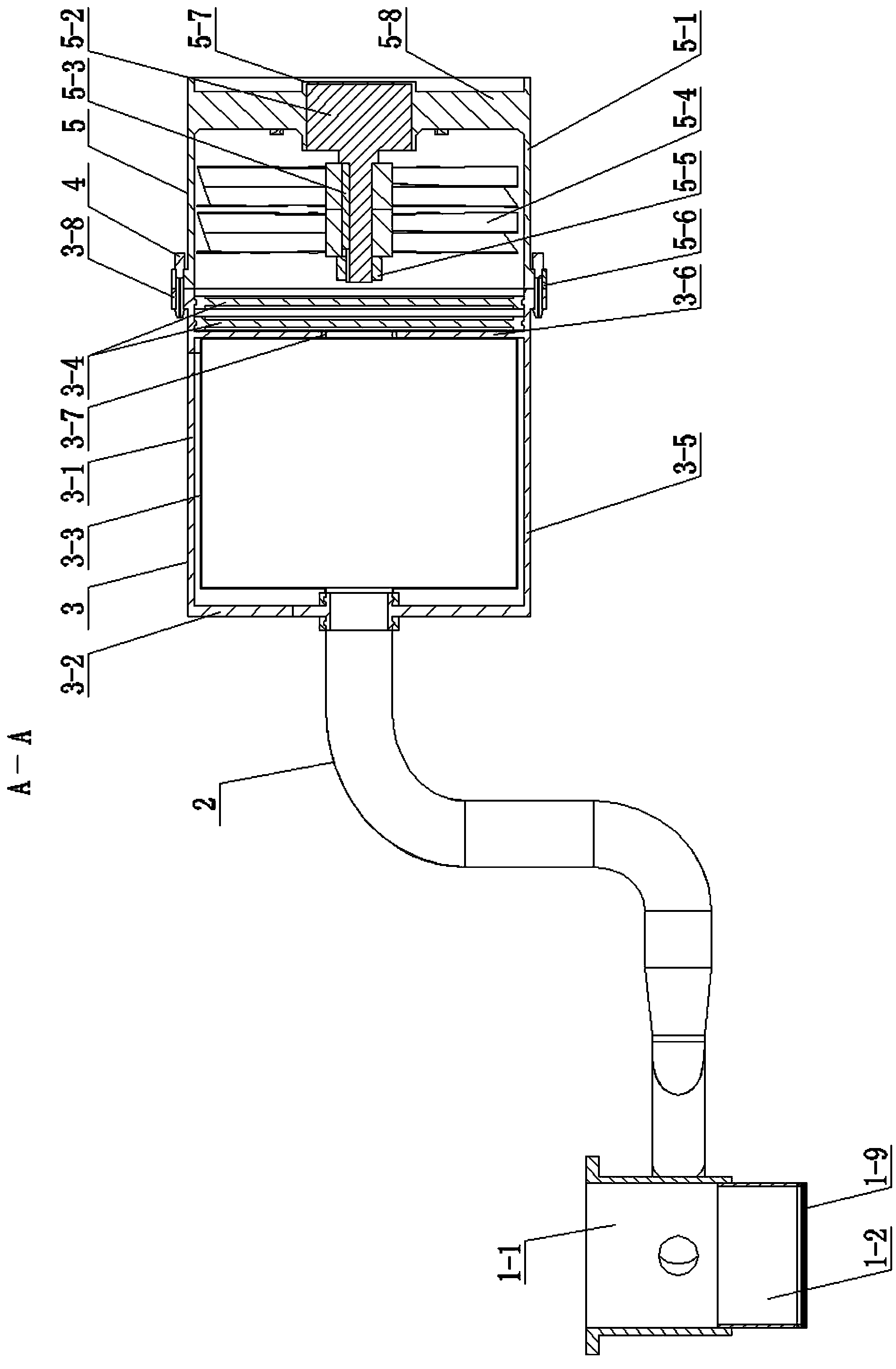

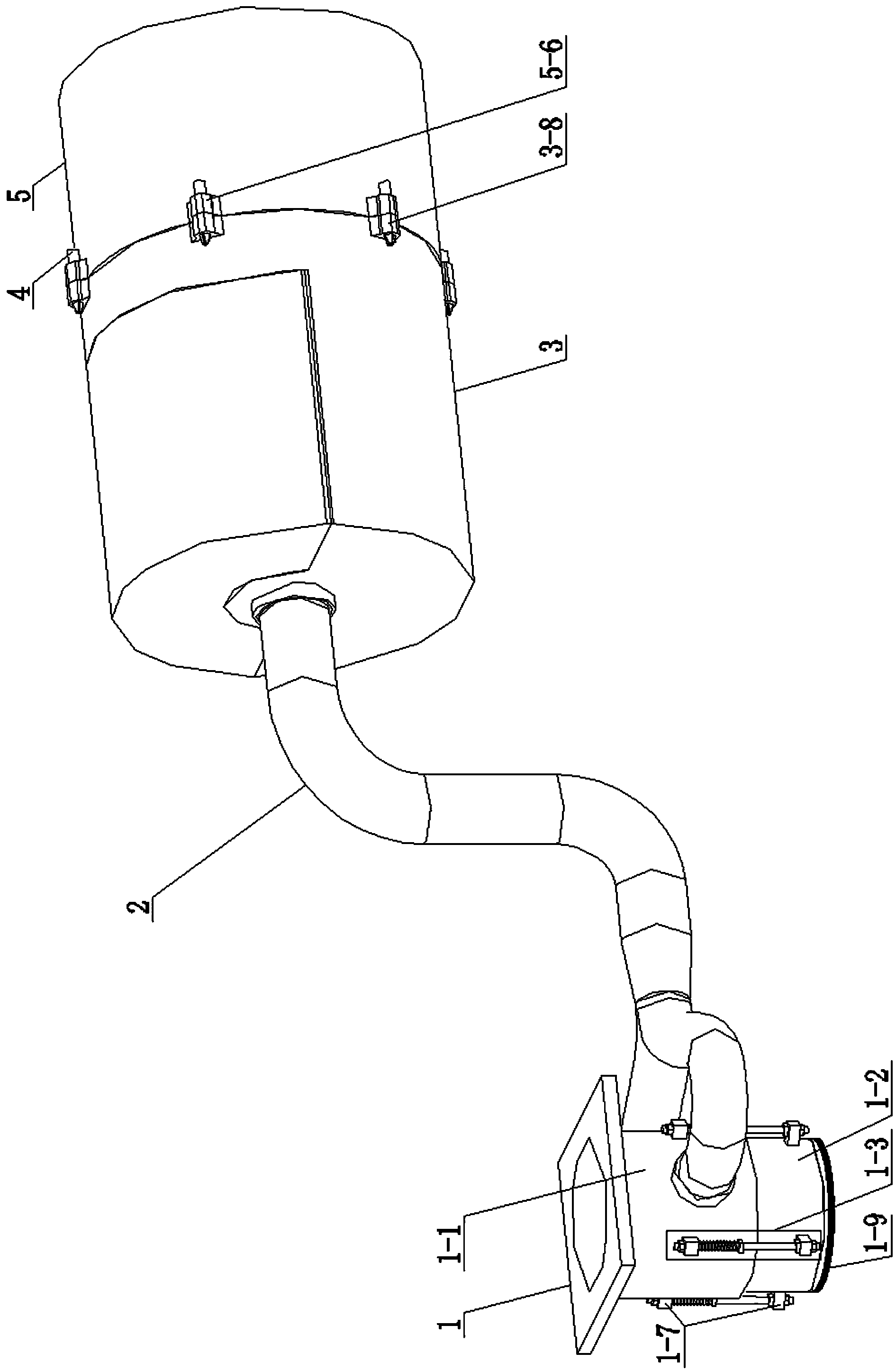

[0019] Such as Figure 1~Figure 9 As shown, the removal material collection and dust removal system during the carbon fiber composite material drilling process includes a retractable dust collection device 1 in the feed direction, an intake manifold 2, a removal material collection and dust removal device 3, a turbofan fan device 5 and multiple Self-locking cotter pin 4; one end of the collection and dust removal housing 3-1 of the removal material collection and dust removal device 3 is a closed end, and the other end is an open end; the fan housing 5-1 of the turbofan fan device 5 Both ends are open ends; the air inlet of the intake manifold 2 is fixedly connected to the side wall of the main shaft connecting sleeve 1-1 of the retractable dust collection device 1 in the feeding direction and is connected to the main shaft. The inner cavity of the sleeve 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com