Hot-pressing compound device and method for producing membrane filter material

A technology of composite equipment and film-coated filter material, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problem of poor dust removal effect, inability to effectively remove dust, poor air permeability of film-coated filter material, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

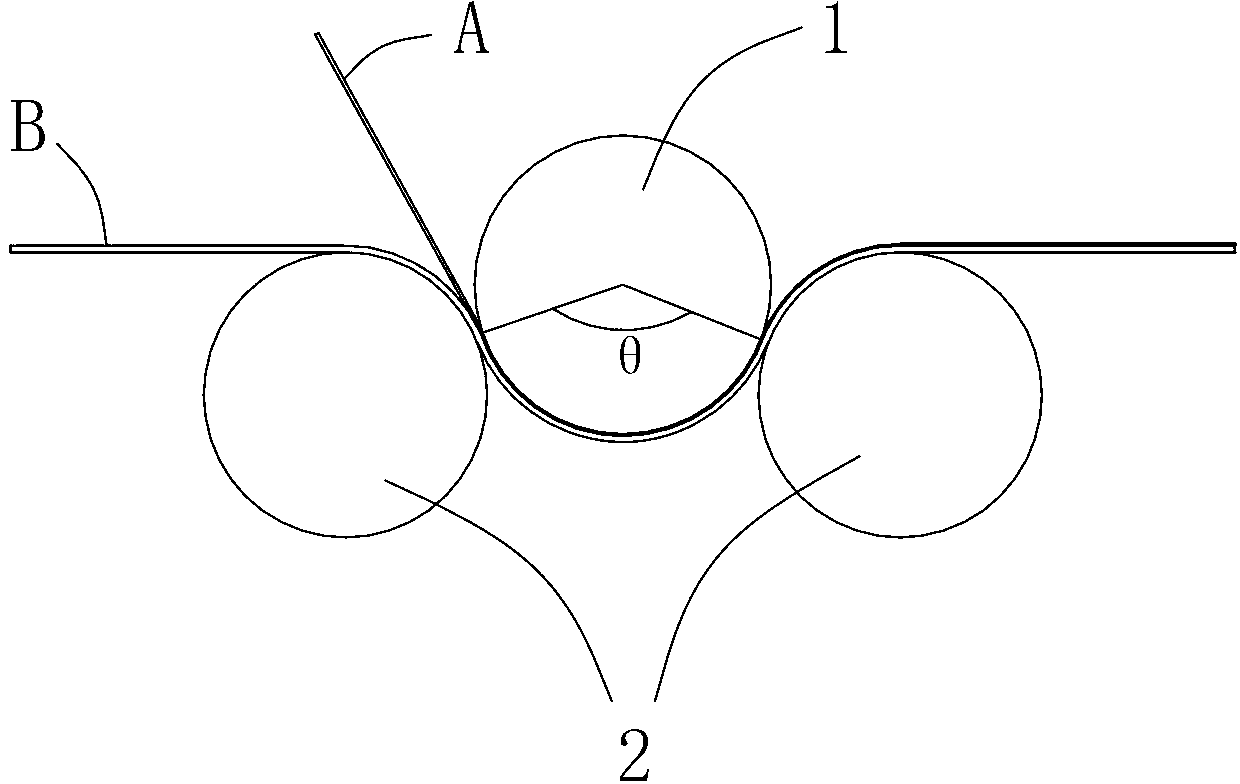

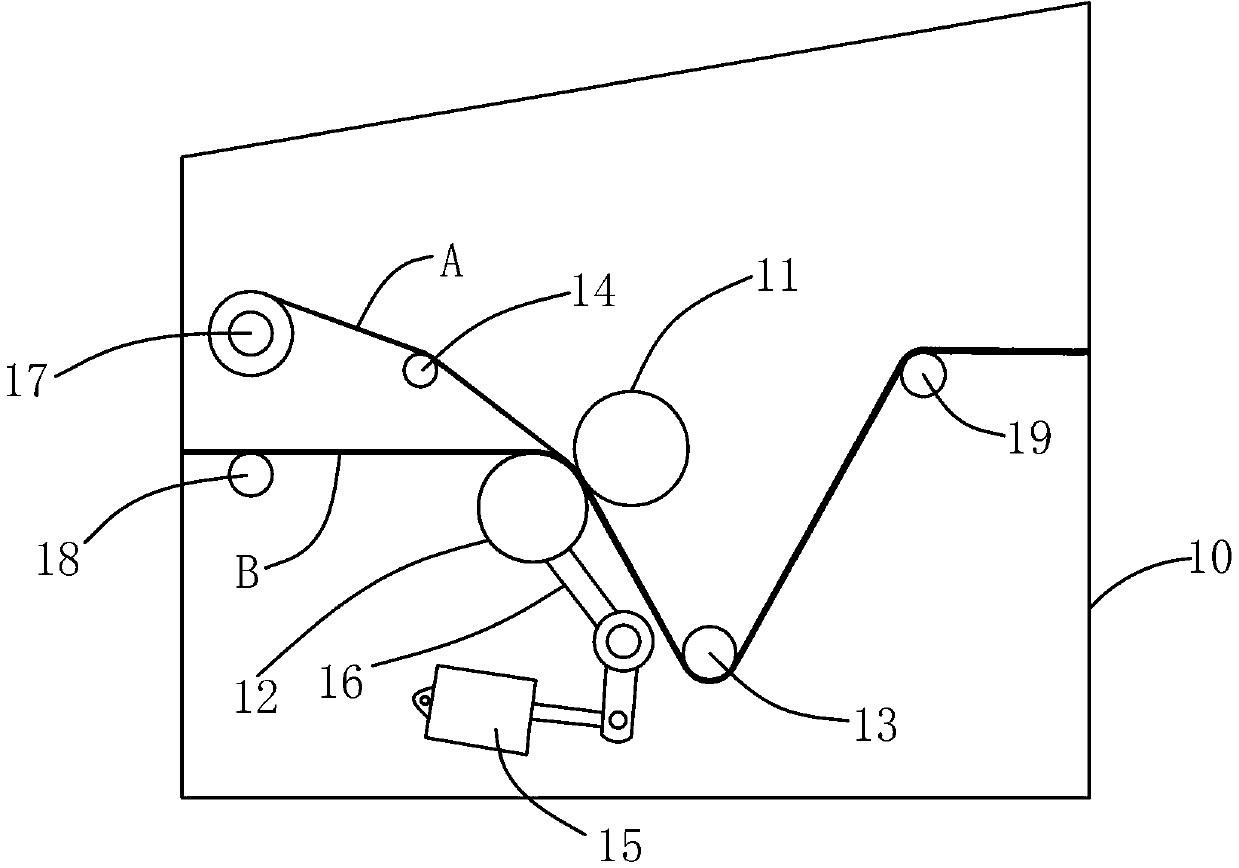

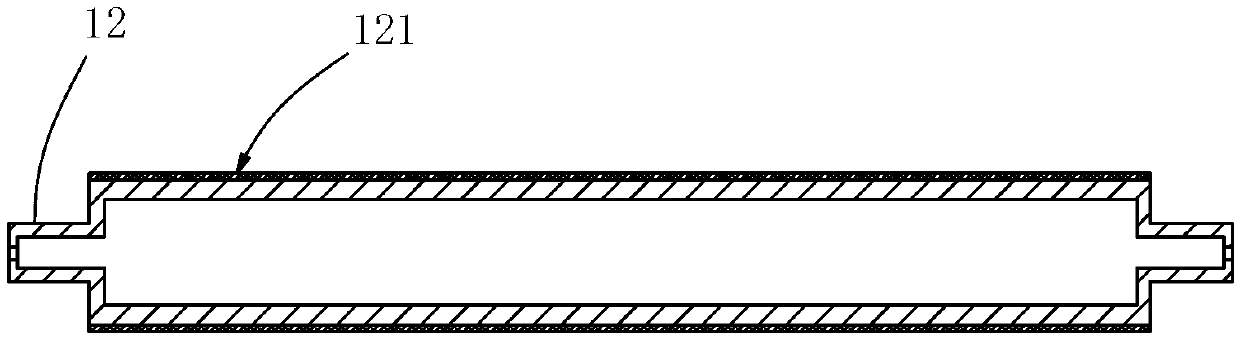

[0013] Through a large number of experimental analysis of the film-coated filter material produced by the traditional hot-pressing composite equipment, it is obtained that the PTFE film A and the base fiber cloth can be effectively compounded without changing the high air permeability and dust removal performance of the PTFE film A itself. The lamination temperature is within a certain range. If the temperature is too high, it will easily cause the PTFE film A to mature. If the temperature is too low, the two cannot be effectively laminated. Although the traditional thermocompression lamination equipment can effectively control the temperature of thermocompression lamination, it uses nip roller 2 to press-coat PTFE film A and glass fiber cloth B to cover the outer surface of heating roller 2 for thermocompression lamination. , that is, the PTFE film A is in surface contact with the heating roller 2, and the conveying rate of the PTFE film A is limited, so that the heating time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com