Internal heat dry distillation furnace

A dry distillation furnace and internal heating technology, which is used in special forms of dry distillation, coke ovens, petroleum industry, etc., can solve the problems of low oil yield, more saturated steam, and low processing capacity of a single furnace, achieve a stable fire layer, reduce The amount of dust, the effect of reducing the side wall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

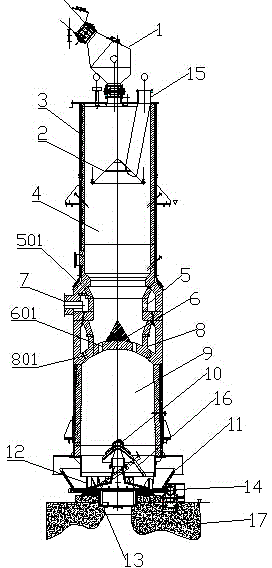

[0015] Such as figure 1 , the internal heating type retort furnace includes a furnace body 3, a charging device 1 arranged on the top surface of the furnace body 3 and an ash discharge device arranged at the bottom of the furnace body 3; the furnace body 3 is the main part of the retort furnace, and its shell is made of steel plate welding , lined with refractory bricks, and the space between the refractory bricks and the shell is filled with sand or insulating rock wool to reduce heat loss. An arch 6 made of refractory bricks is arranged in the middle of the furnace body 3, and an annular upper mixing chamber 5 and an annular lower mixing chamber 8 made of refractory bricks are arranged on the inner wall of the furnace body 3 corresponding to the arch 6. The upper and lower mixing chambers 5 and 8 are communicated, the lower mixing chamber 8 is provided with a gas generating inlet 801 communicating with the gasification section 9, and the upper mixing chamber 5 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com