Centrally-feeding swirl pulverized coal combustion device adopting double-layer jet flow of separated secondary air

A pulverized coal combustion and pulverized coal burner technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of poor emission reduction effect, furnace slagging, etc., and achieve strong air classification, enhanced reducibility, and coal adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

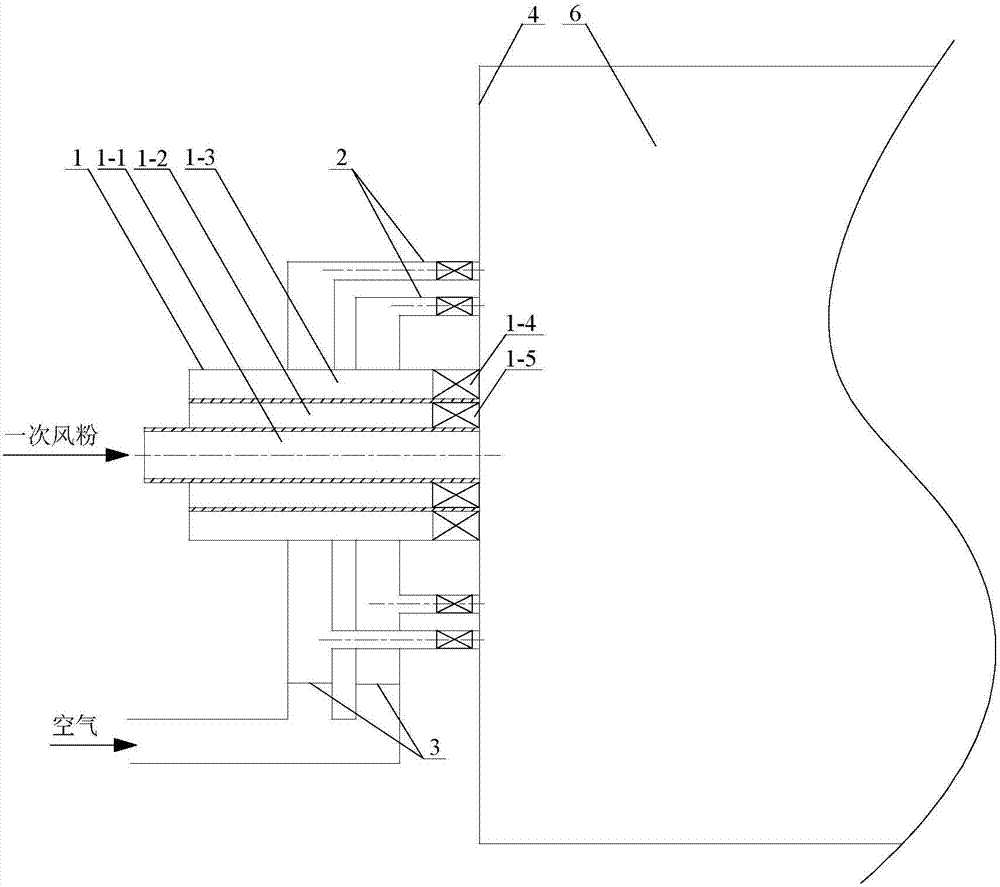

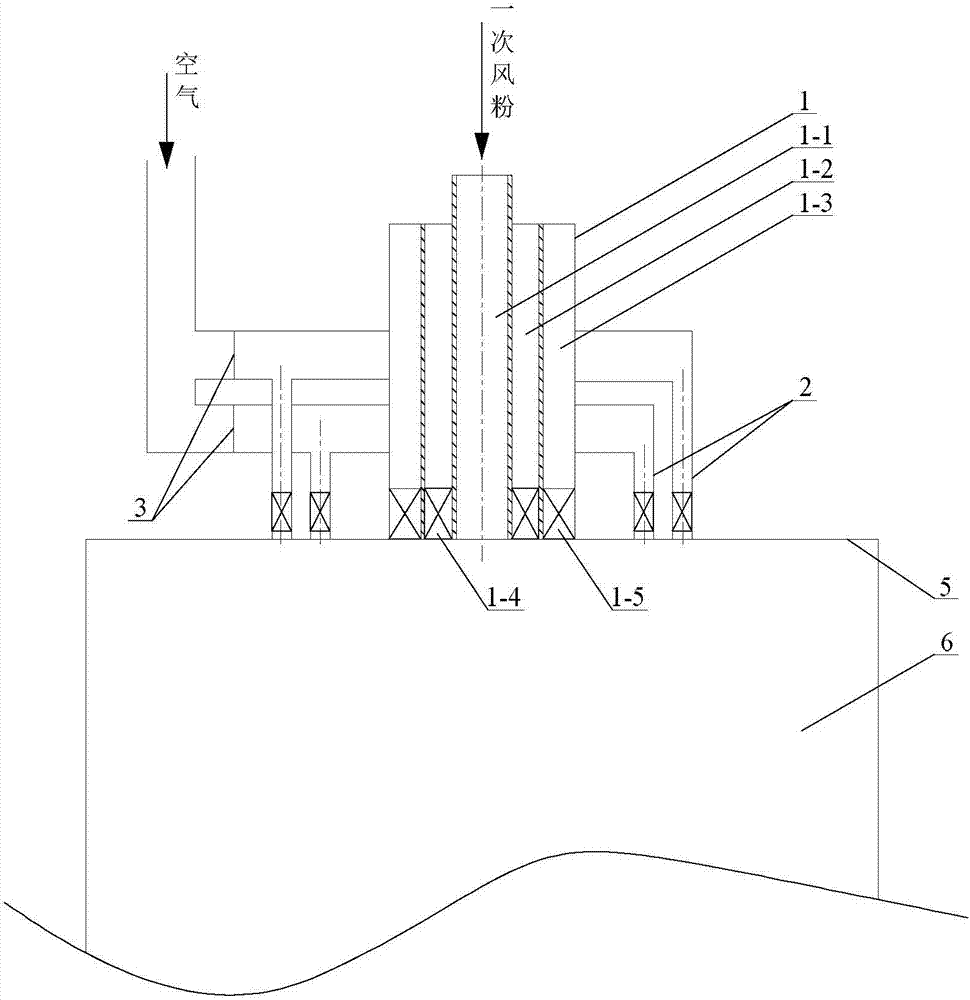

[0024] Specific implementation mode one: as Figure 1~2 As shown, the center-feeding swirl pulverized coal combustion device using separated secondary air double-layer jets in this embodiment includes a swirl pulverized coal burner 1, a plurality of separated secondary air pipes 2 and a plurality of separated secondary windshields Plate 3; the swirl pulverized coal burner 1 is arranged on the front wall 4 of the boiler or is located on the roof 5 of the vertical boiler, and the swirl pulverized coal burner 1 includes a primary air duct 1-1, a secondary air duct in the swirl The air duct 1-2 and the secondary air duct 1-3 outside the swirl, the primary air duct 1-1 is arranged in the secondary air duct 1-2 inside the swirl and is located in the secondary air duct 1-2 inside the swirl Center position, the secondary air duct 1-2 inside the swirl is set in the secondary air duct 1-3 outside the swirl, the primary air duct 1-1, the secondary air duct 1-2 inside the swirl and the ou...

specific Embodiment approach 2

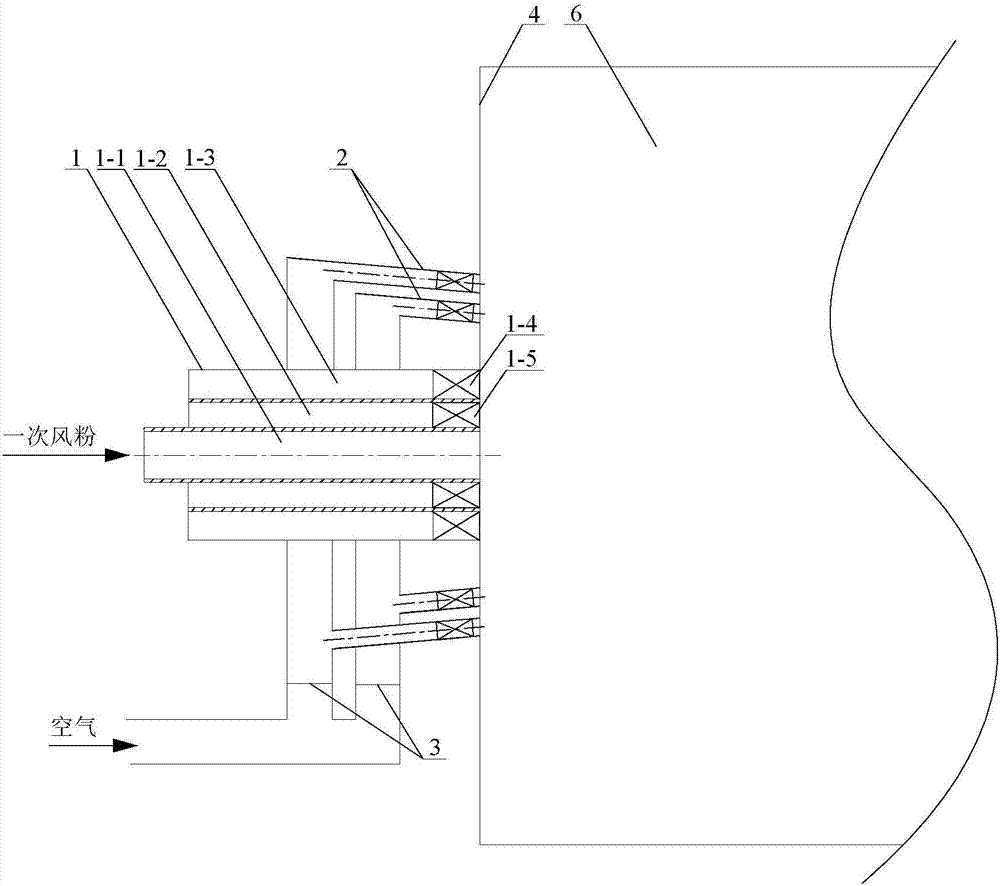

[0026] Specific implementation mode two: as image 3As shown, the angle between the axis of the separated secondary air duct 2 and the inner wall of the furnace in this embodiment is adjustable, and the angle between the axis of the separated secondary air duct 2 and the axis of the swirl pulverized coal burner 1 is ±30 °. Such a design makes the separated secondary air form a rotating jet and enter the furnace 6 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: as Figure 1~3 As shown, in this embodiment, the first axial swirl blades 1-4 are arranged on a side close to the inner wall of the furnace 6 . With such a design, the swirl strength in the secondary air pipe 1-3 outside the swirl can be adjusted. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com