Efficient desulfurizing tower

A desulfurization tower and high-efficiency technology, applied in the field of environmental protection equipment, can solve the problems of adverse effects of the use of the desulfurization tower, scratches on the inner wall of the desulfurization tower, prone to cracking, falling off, etc., to save internal space, high water mist removal rate, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

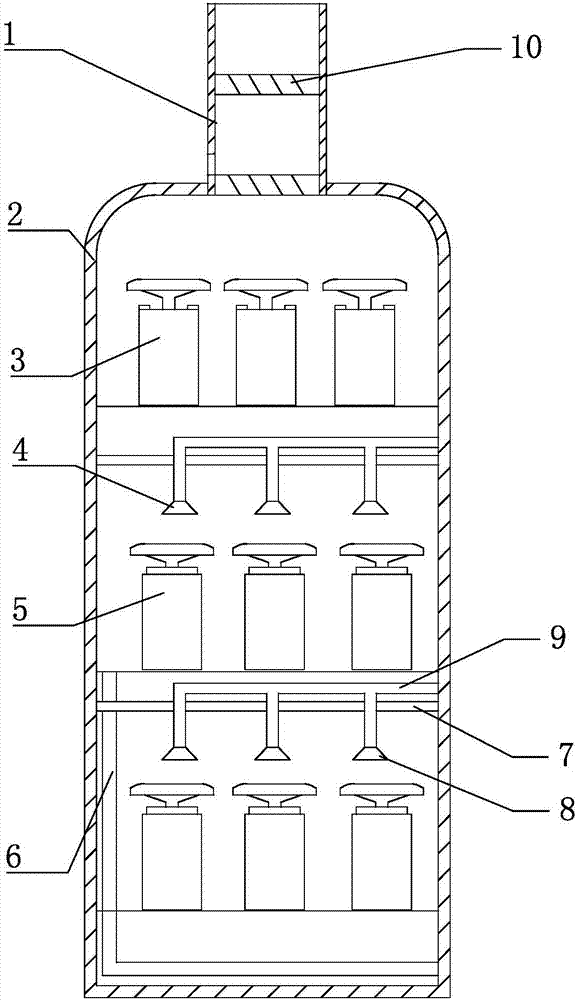

[0044] Such as Figure 1 to Figure 7 As shown, a high-efficiency desulfurization tower includes a tower body 2, a smoke outlet is provided on the top of the tower body 2, a multi-stage spraying system is provided in the tower body 2, and multiple fog and dust removal systems are provided at the bottom of each stage of the spraying system device 5, a plurality of mist and dust collectors 5 are arranged in parallel. The tower body 2 is also provided with a smoke outlet demist and dust collector 3, which is arranged near the smoke outlet.

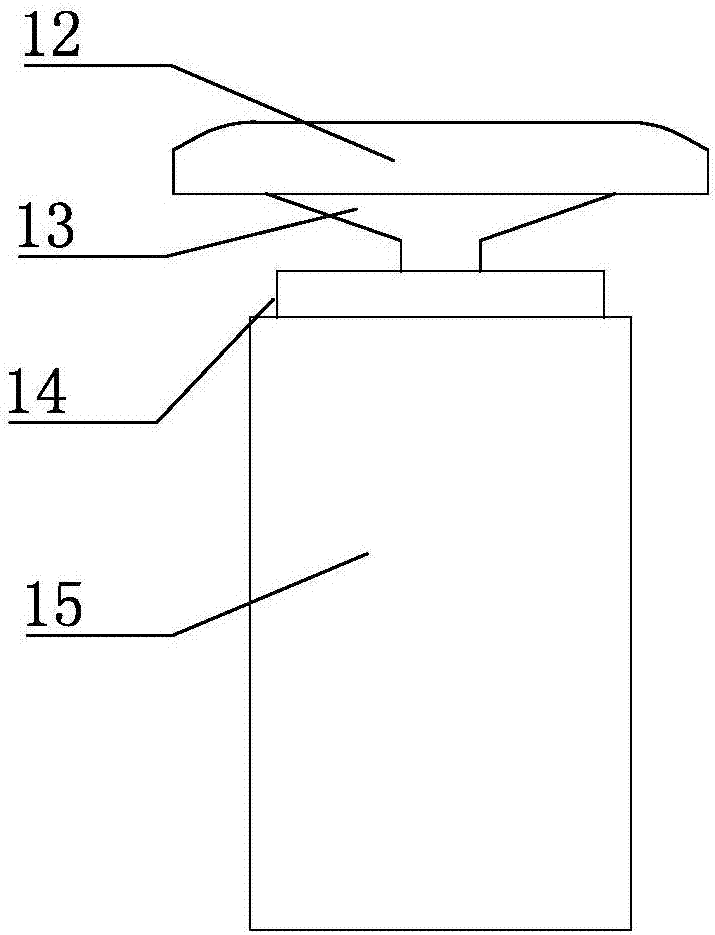

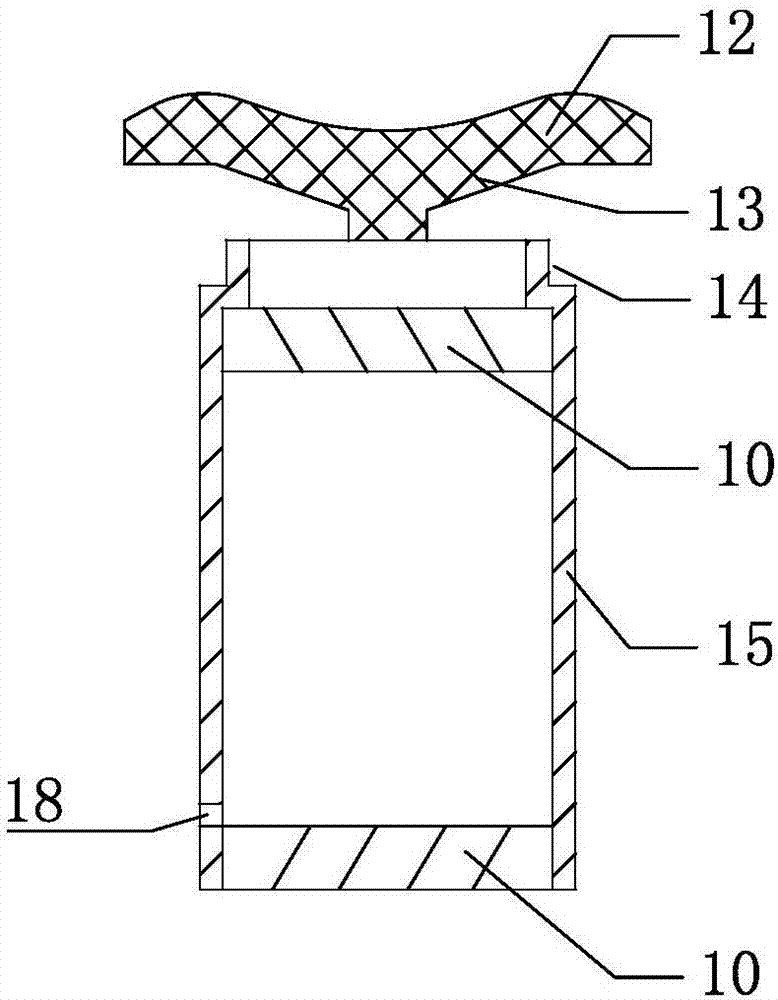

[0045] The structures of the demist and dust remover 5 and the smoke outlet demist and dust remover 3 all include a housing 15, the upper end and the bottom of the housing 15 are respectively provided with a swirl plate 10, and the swirl plate 10 includes a swirl blade 17, two swirl plates The rotation direction of the swirl vanes of the plate 10 is opposite. A water return port 18 is provided on one side of the bottom end of the casing 15 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com