Gradient adjusting type self-cleaning infrared monitor

A technology of self-cleaning and monitoring, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of easy dust falling, inability to filter infrared rays, etc., and achieve cleanliness, good adaptation effect, The effect of good imaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

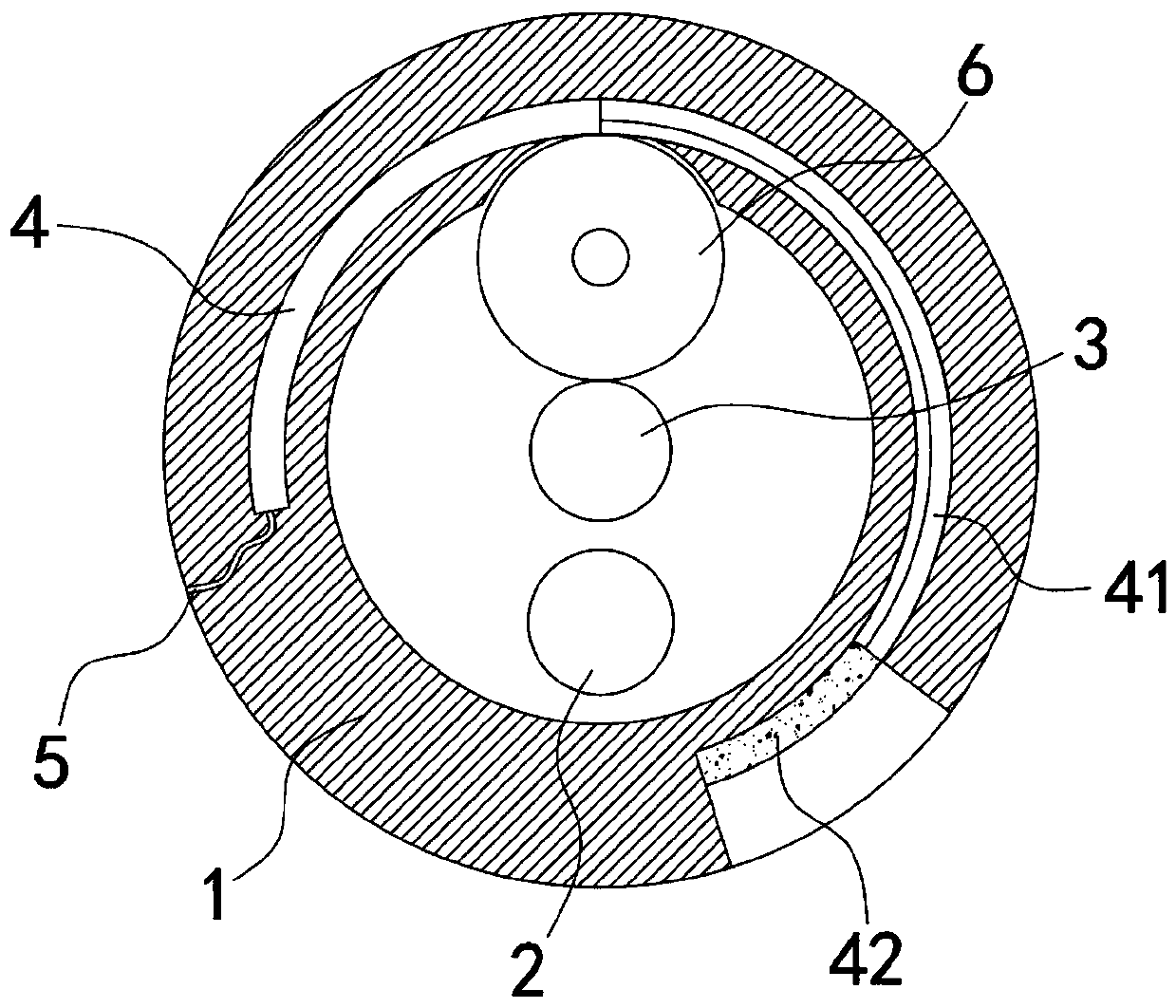

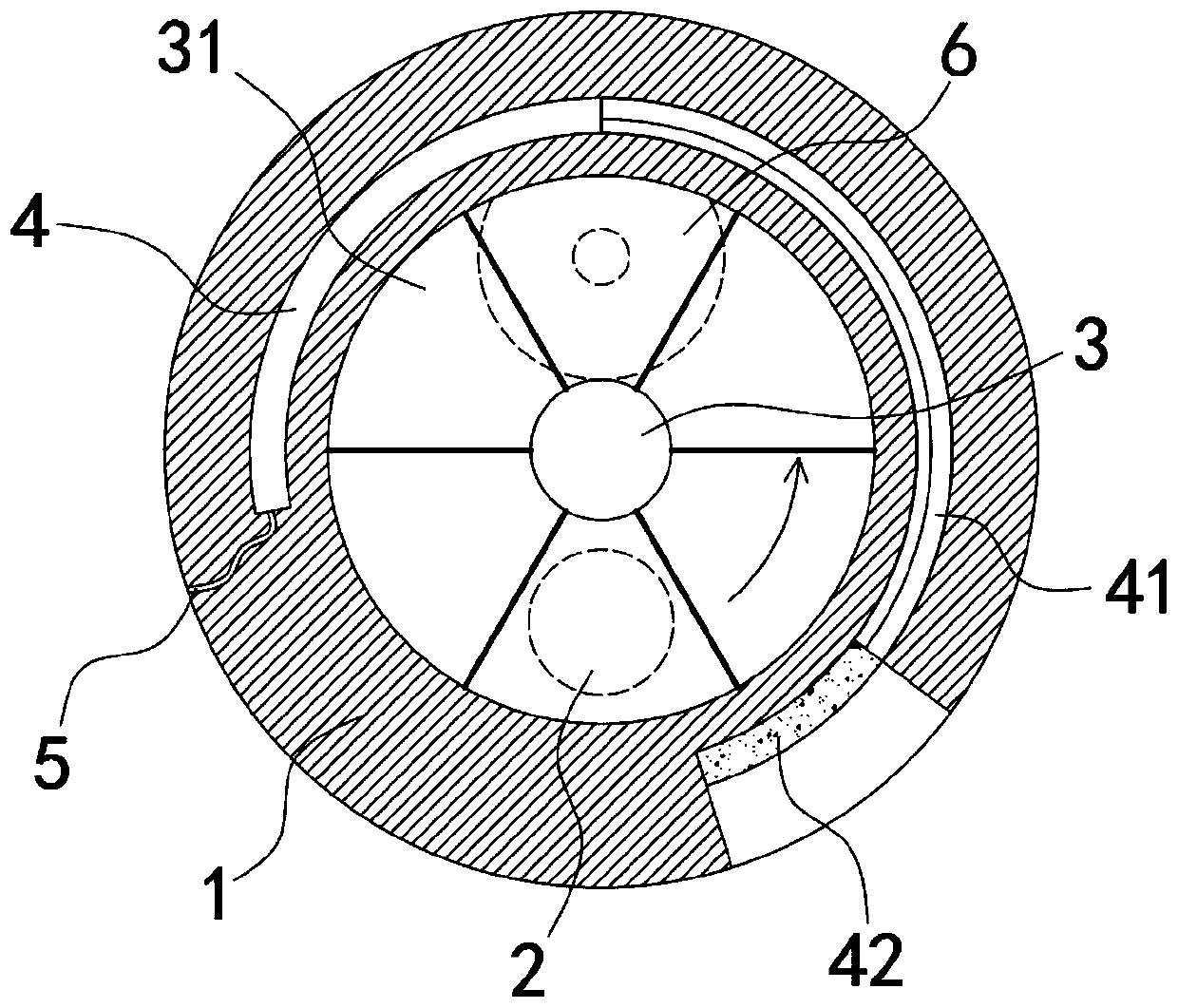

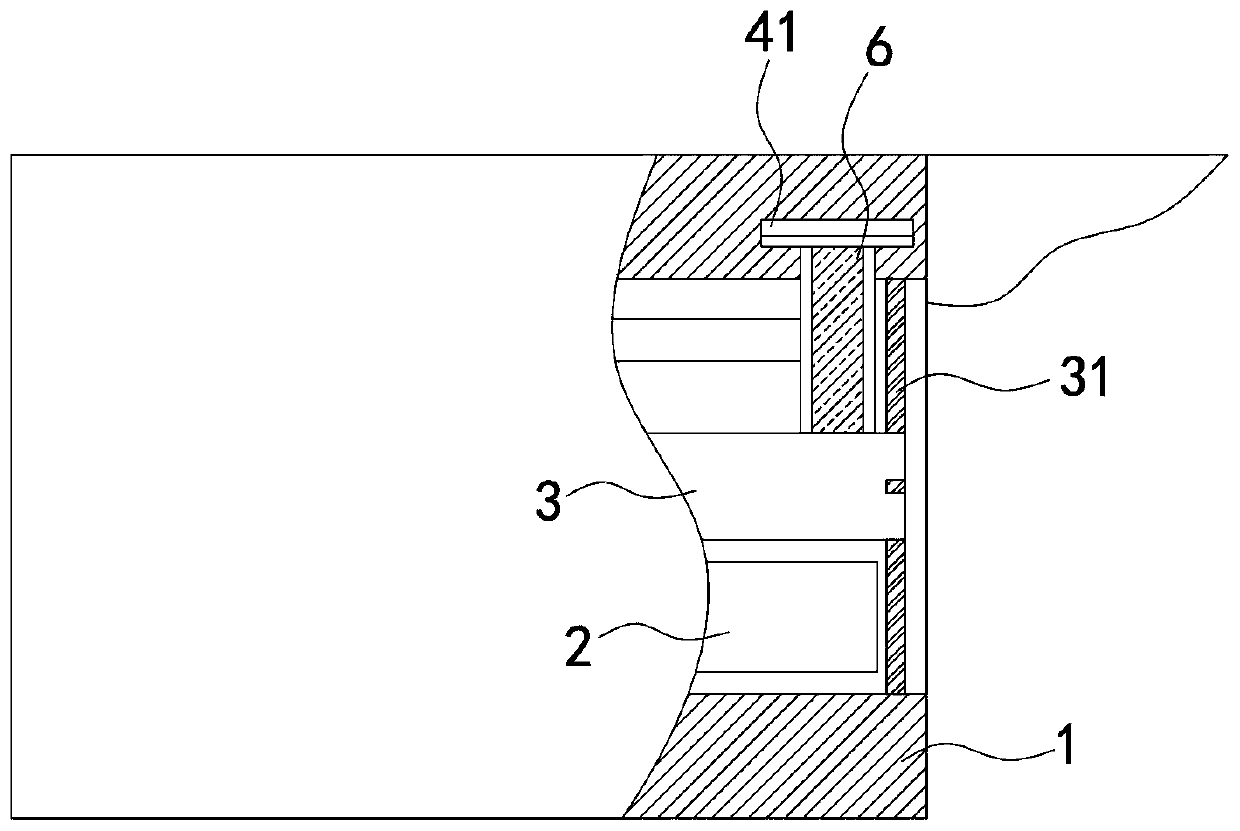

[0021] Such as Figure 1-3 As shown, a gradually adjustable self-cleaning infrared monitor includes a cylindrical housing 1 and a monitoring head 2, the monitoring head 2 is installed on the lower half of the housing 1, that is, the monitoring head 2 is installed on the axis of the housing 1 At the following positions, the center of the housing 1 is coaxially connected to the drum 3, and the front side wall of the drum 3 is fixedly connected to the filter plate 31, and the filter plate 31 is spliced by a plurality of fan-shaped plates with successively increasing filter intensity. , and the filter intensity of multiple fan-shaped plates for infrared rays is along the figure 2 The directions of the arrows increase in turn. Specifically, the infrared film can be pasted on the fan-shaped boards to achieve infrared filtering, and different layers of infrared films can be pasted on each fan-shaped board to achieve different filtering intensities. In the initial state, the same a...

Embodiment 2

[0026] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that: the outer front end of the housing 1 is rotatably connected with a circular transparent plate 7, and the transparent plate 7 is provided with an arc-shaped tube 8 concentric with the transparent plate 7, One end of the arc tube 8 is airtightly connected to the pressure stabilizing passage 5, and the other end is open. A magnetic piston block 81 is connected to the arc tube 8 in a sealed and sliding manner. The connecting strip 71 sucked, the piston block 81 can drive the connecting strip 71 to move thereupon when sliding along the arc tube 8, the front end side wall of the housing 1 is fixedly connected with the cleaning strip 72 that fits the transparent plate 7 and arranges.

[0027] In this embodiment, when the arc-shaped friction strip 41 rotates, the air in the arc-shaped cavity 4 will be squeezed into the arc-shaped tube 8 through the pressure-stabilizing passage 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com