Powder-feeding head dust-collecting device for coaxial powder-feeding equipment

A dust removal device and coaxial powder feeding technology, which is applied in the field of 3D printing, can solve the problems of fire hazards and spark phenomena, and achieve good dust removal effect, improved dust removal effect, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

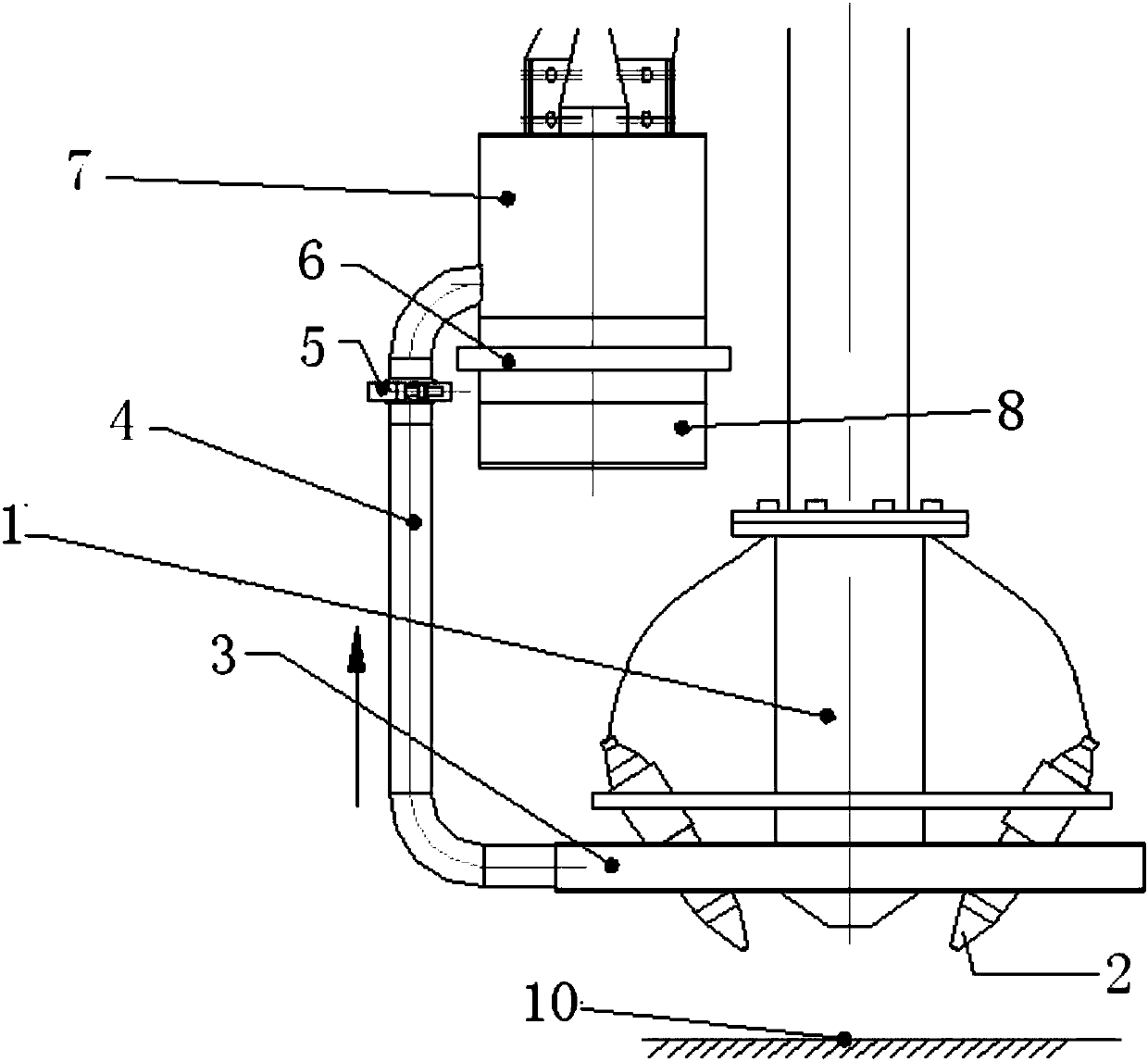

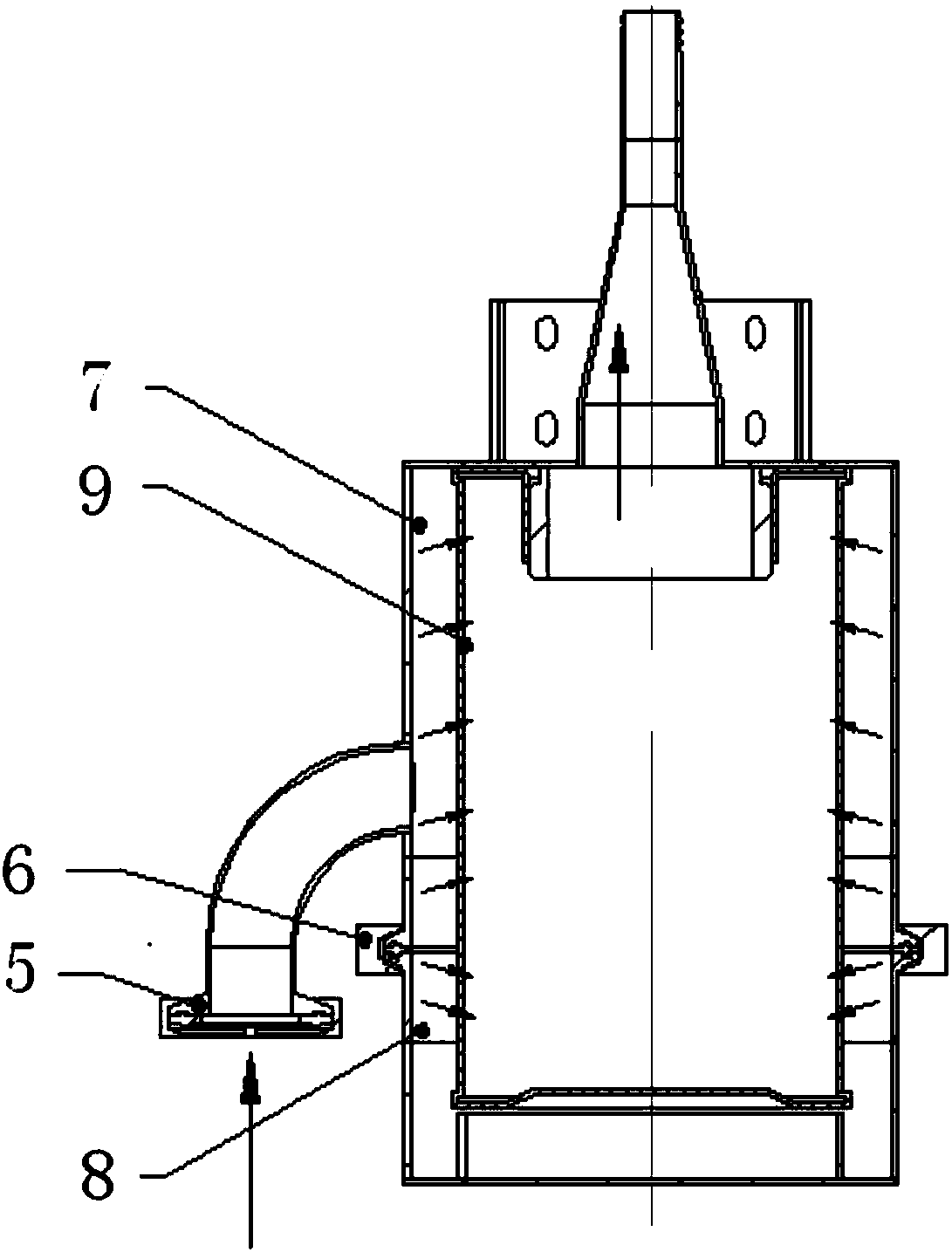

[0032] Refer to attached Figures 1 to 4 As shown, the coaxial powder feeding device in this embodiment includes a sealed cavity 20 , and the powder feeding head 1 and the molding surface 10 are located inside the sealed cavity 20 . The dust removal device includes a dust suction mechanism, a filter mechanism and a power mechanism.

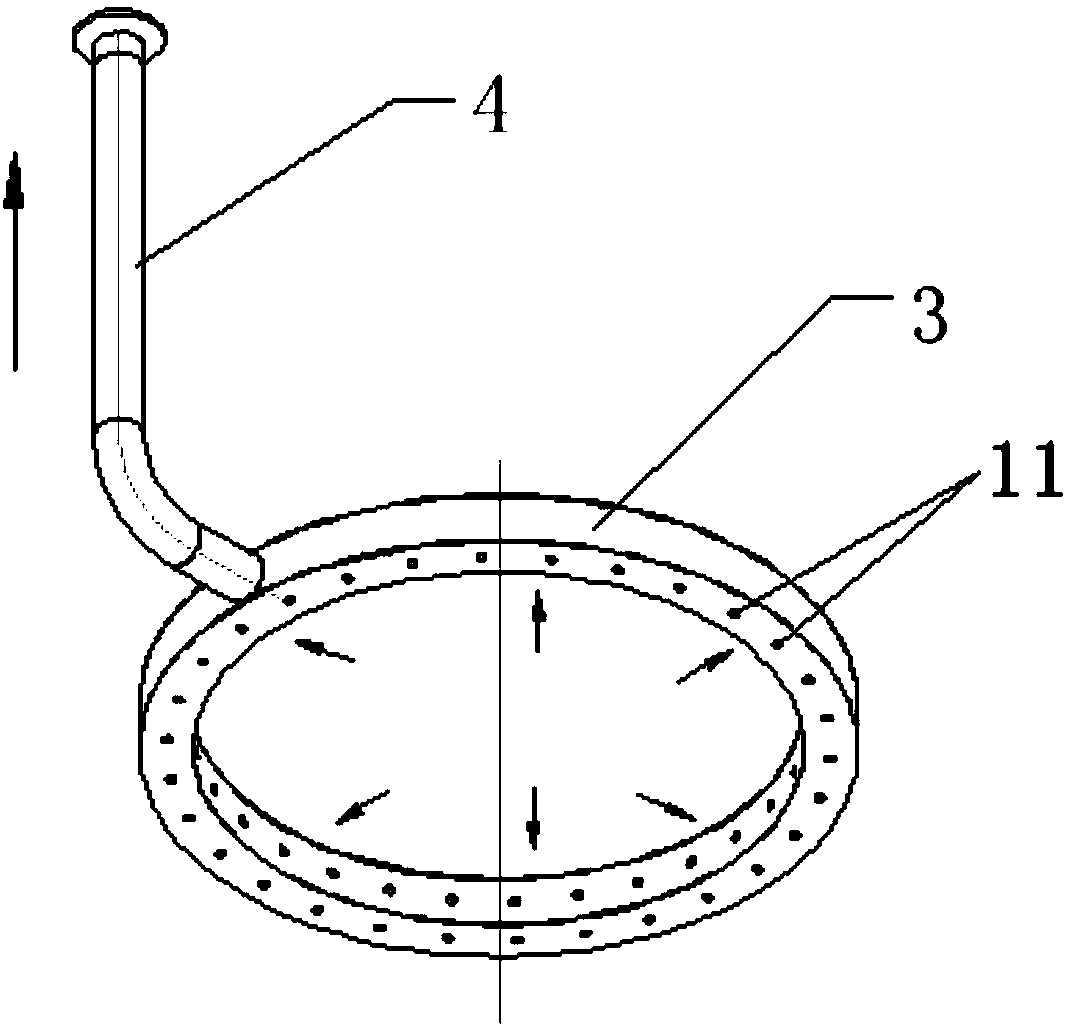

[0033] The dust-absorbing mechanism is arranged above the powder-feeding nozzle 2 of the powder-feeding head 1, and it is preferably arranged on the annular dust-absorbing pipe 3 around the powder-feeding nozzle 2, and the annular dust-absorbing pipe 3 is provided with several dust-absorbing holes 11. The dust suction hole is distributed on the bottom and the inner side wall of the annular dust suction duct 3, as attached image 3 shown. The size of the suction hole can be designed according to the characteristics of the fluid, and the air intake flow of all the suction holes is uniform.

[0034] The dust suction mechanism is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com