Solid rocket engine jet pipe blanking cap blanking die

A technology of engine nozzles and solid rockets, applied in the field of stamping dies, can solve problems such as complex production processes, low efficiency, and inability to ensure personnel safety, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

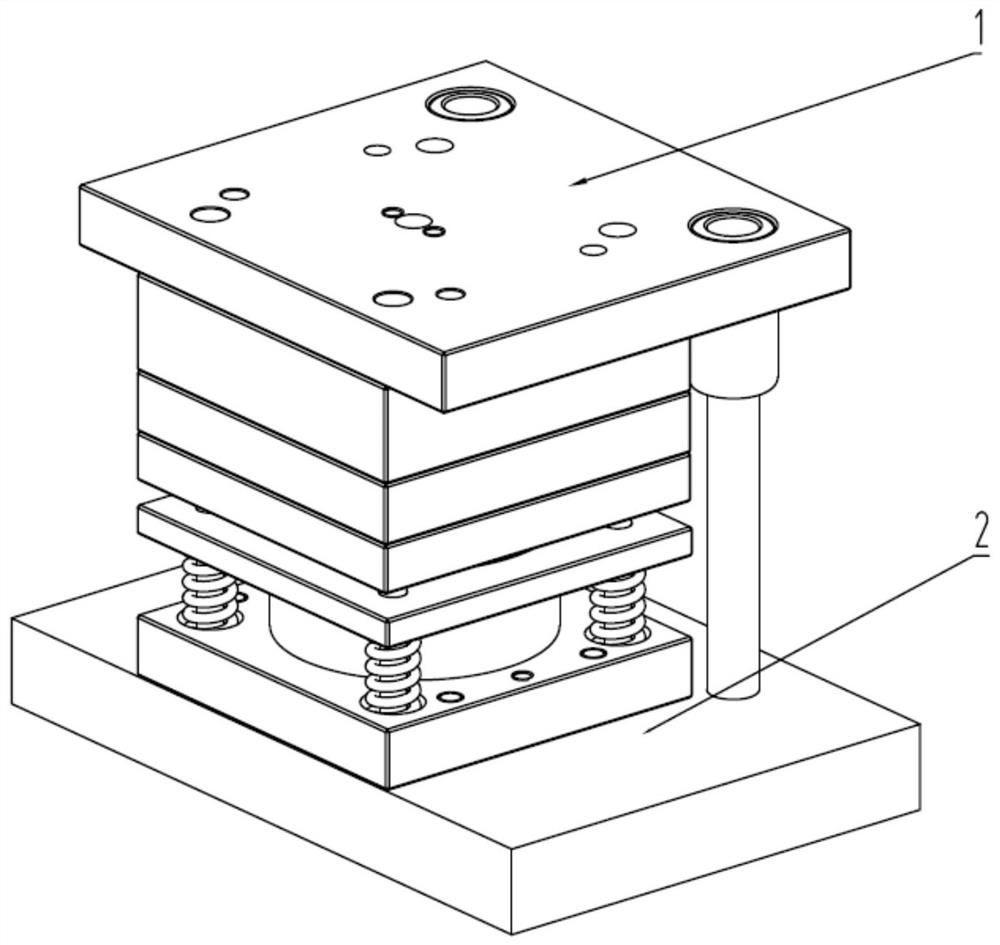

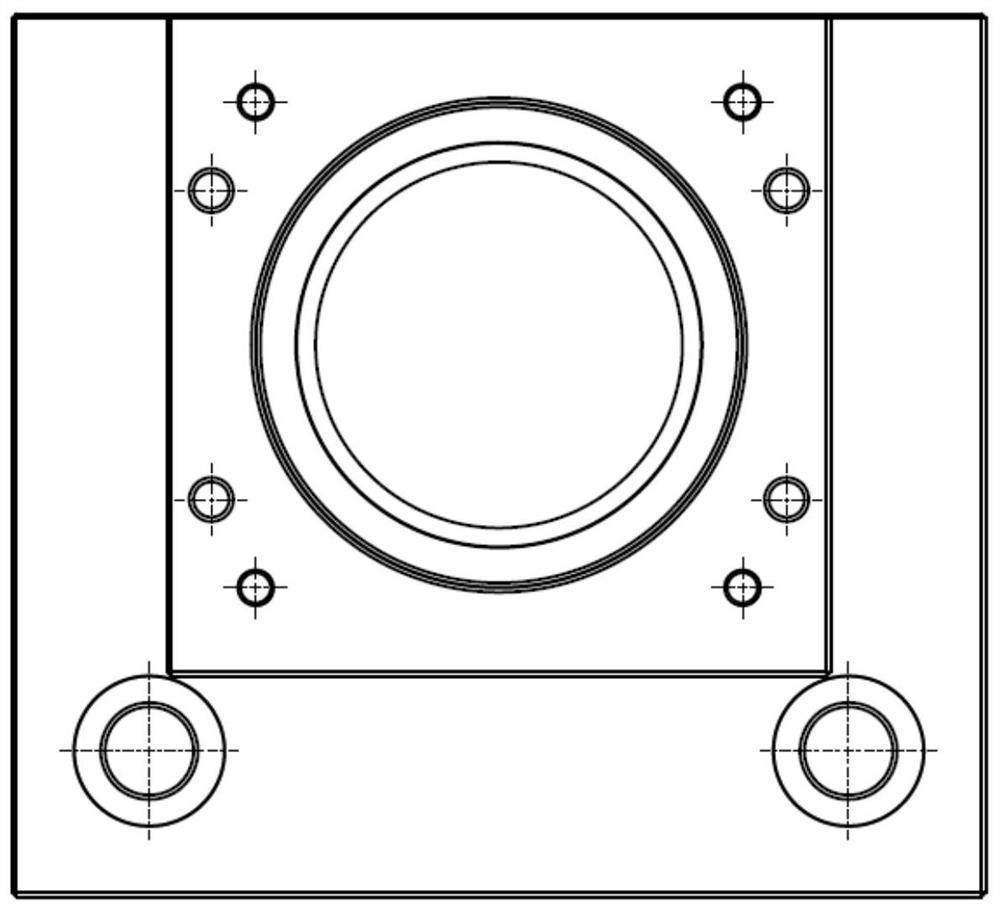

[0042] Such as figure 1 and figure 2 , in this embodiment, the solid rocket motor nozzle cap blanking die, including: an upper die 1 and a lower die 2. Wherein, the upper mold is installed on the slider of the stamping machine tool to realize the forming of the inner surface of the plug; the lower mold is installed on the working table of the stamping machine tool to realize the forming and unloading of the outer surface of the plug.

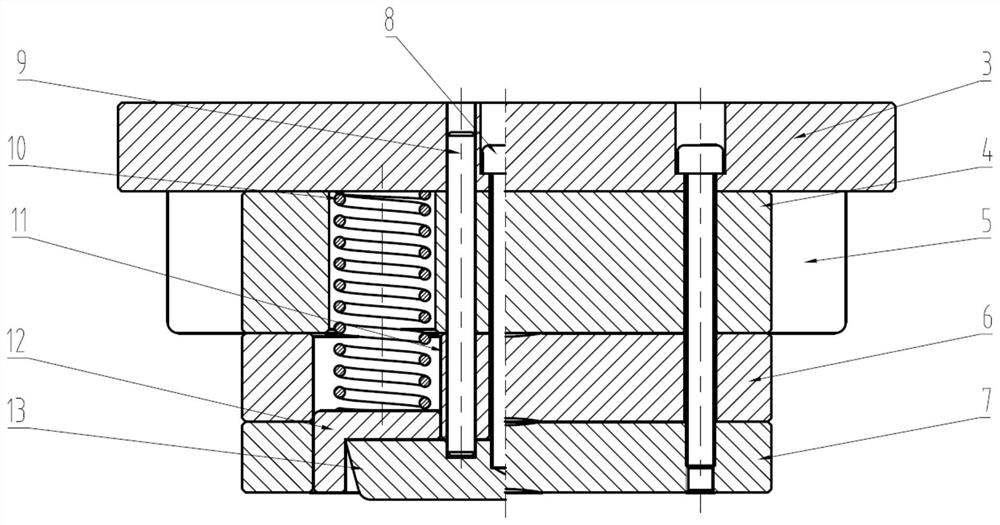

[0043] In this example, if image 3 , the upper mold 1 may specifically include: upper mold base 3, backing plate 4, guide bushing 5, punch fixing plate 6, upper cutting plate 7, fixing bolt 8, positioning pin 9, spring 10, punch top shaft 11. Upper discharge block 12 and punch 13. The specific conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com