Insulation pad butt cutting machine

A technology for insulating rubber pads and cutting machines, which is applied to cleaning methods and appliances, chemical instruments and methods, household appliances, etc., which can solve the problems of non-straight cutting of insulating rubber pads, waste of resources, and low efficiency, and improve the cutting work. Efficiency, solve the effect of cutting is not straight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

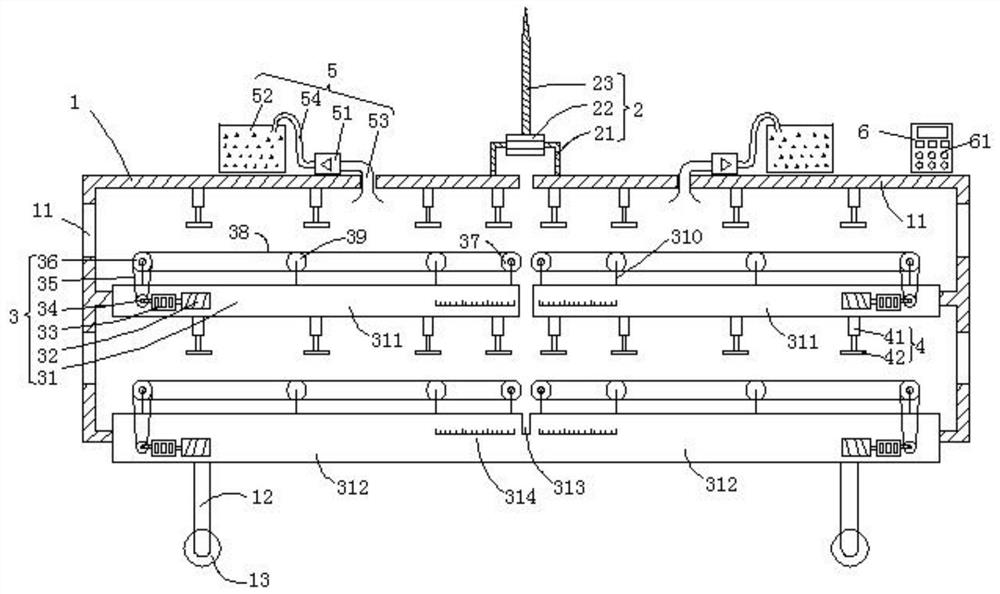

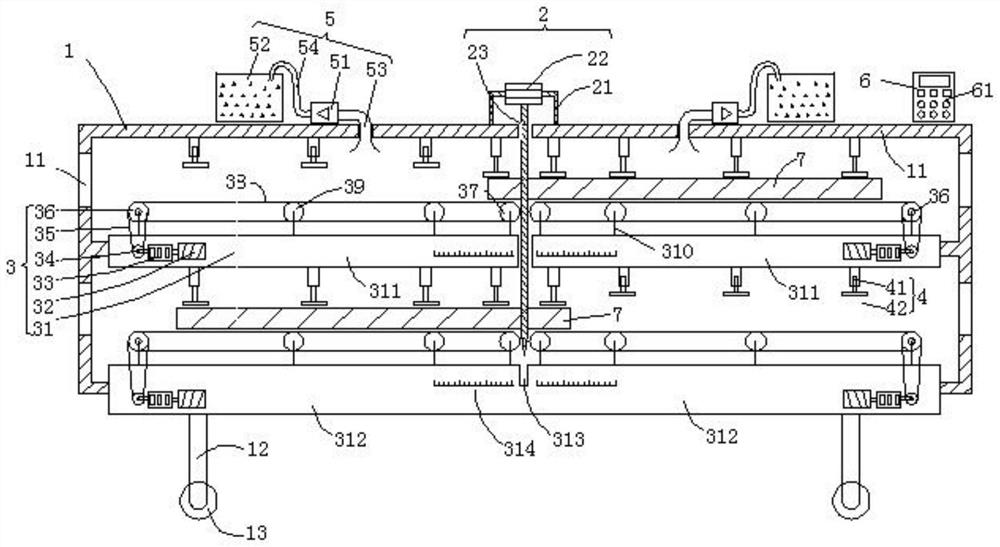

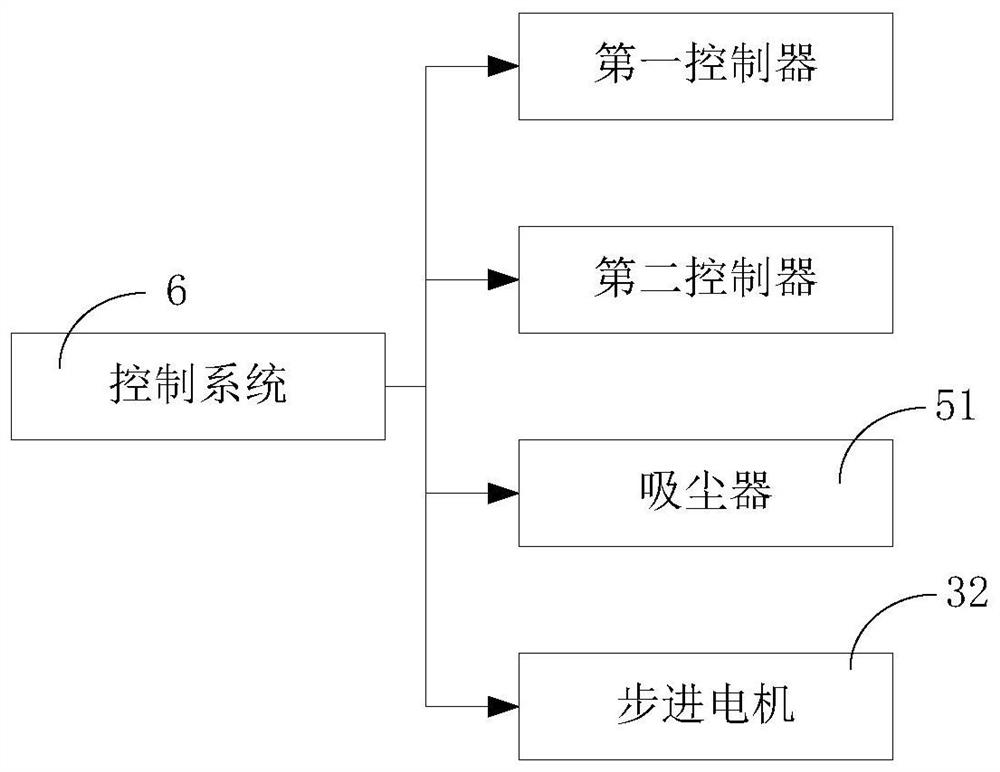

[0032] Furthermore, please also refer to Figure 1 to Figure 3 , as a specific embodiment of the insulating rubber pad butt joint cutting machine provided by the present invention, the dust removal mechanism 5 includes a vacuum cleaner 51 installed on the top of the frame 1, a dust storage box 52, and a vacuum cleaner 51 installed between the inlet and the The dust suction pipe 53 leading to the inner cavity of the frame 1 , and the dust discharge pipe 54 installed between the outlet of the dust collector 51 and the dust storage box 52 , and the dust collector is controlled by the control system 6 . The dust removal mechanism 5 can suck away the debris after cutting in the inner cavity of the frame 1, thereby reducing environmental pollution and protecting personal health.

[0033] Furthermore, please also refer to Figure 1 to Figure 3 As a specific embodiment of the insulating rubber pad docking and cutting machine provided by the present invention, the pressing mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com