Full-automatic cut-off machine

A cutting machine, fully automatic technology, applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve the problems of low production efficiency, high labor intensity, laborious and laborious, and achieve the goal of reducing processing costs and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

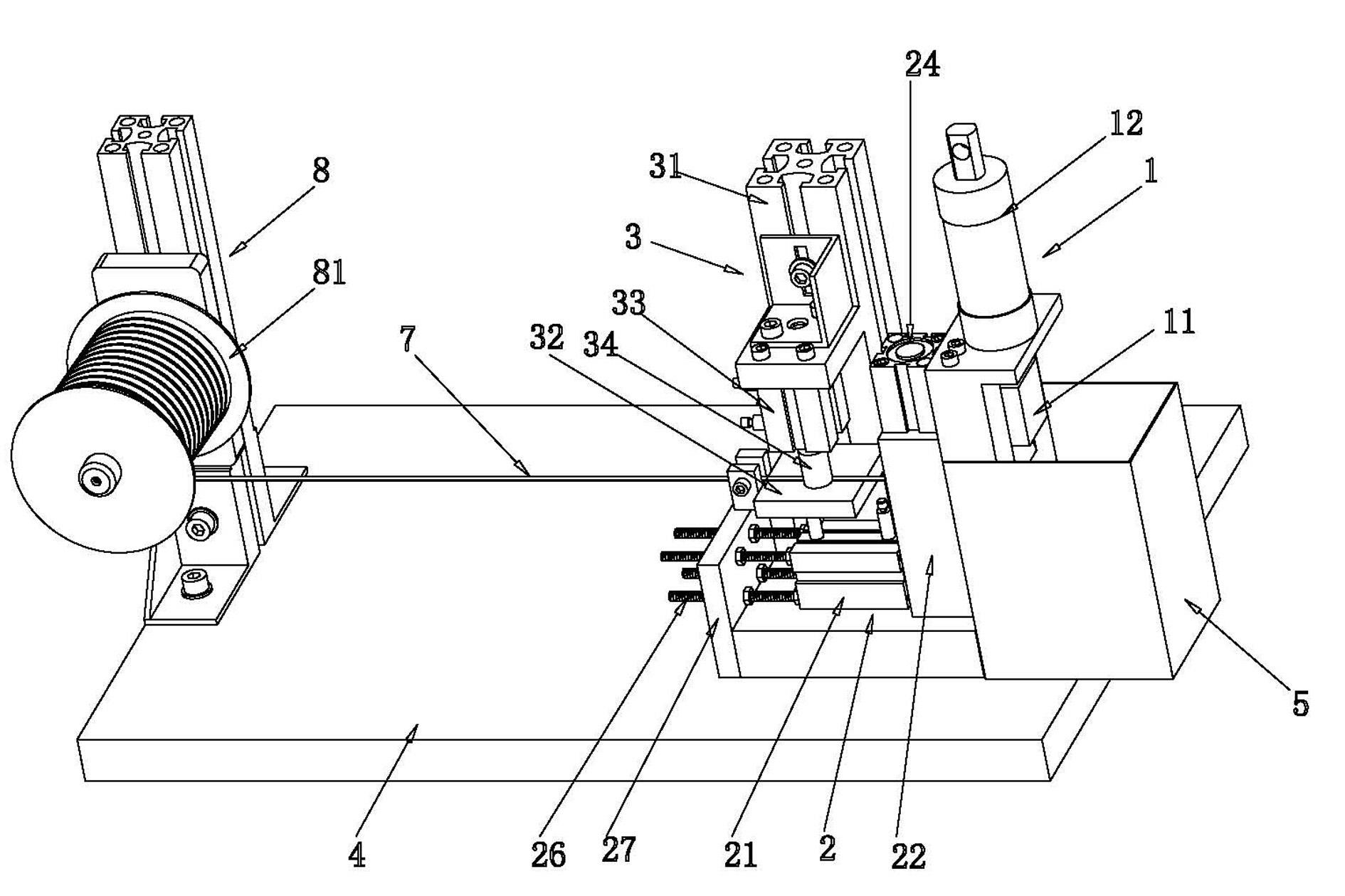

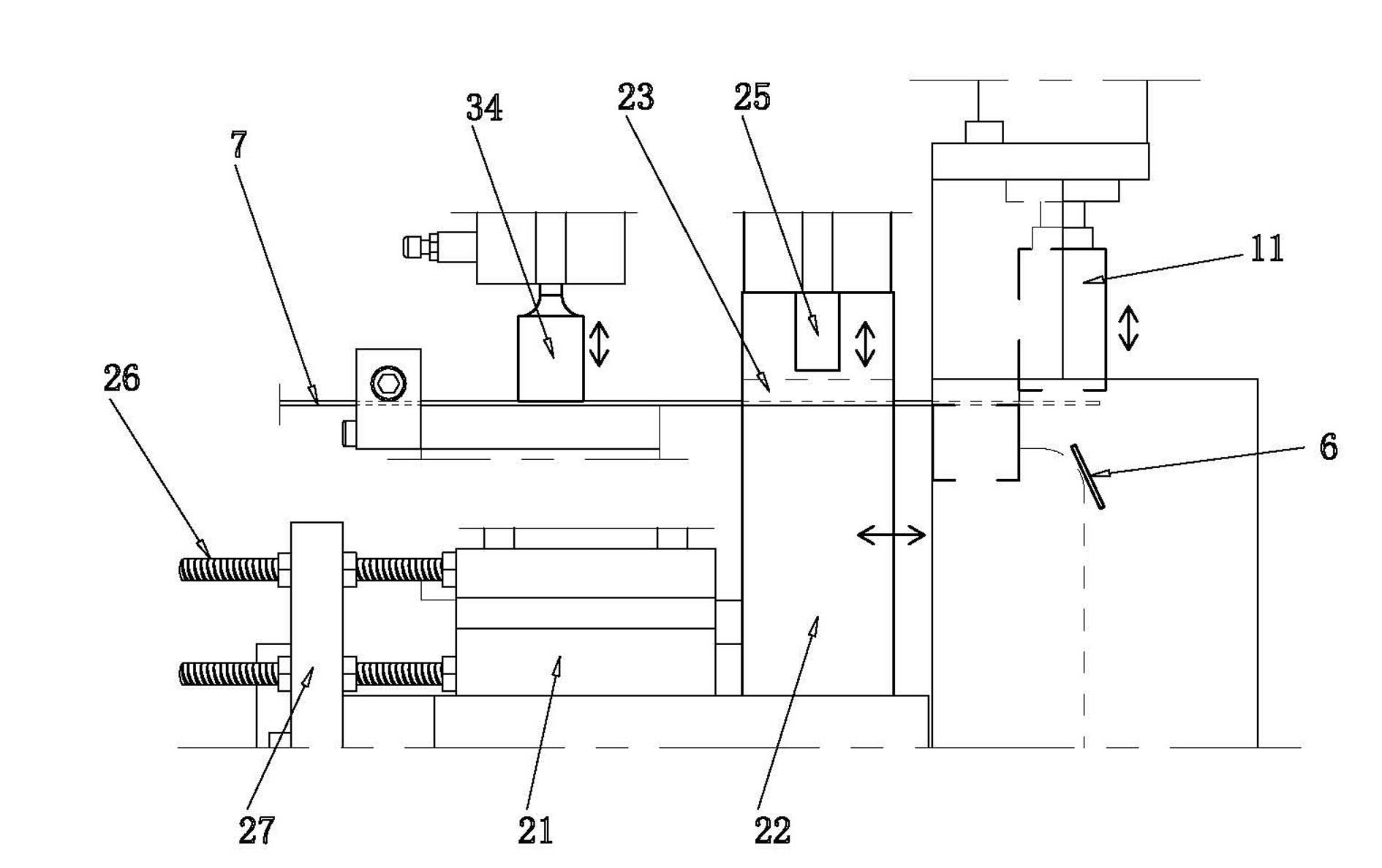

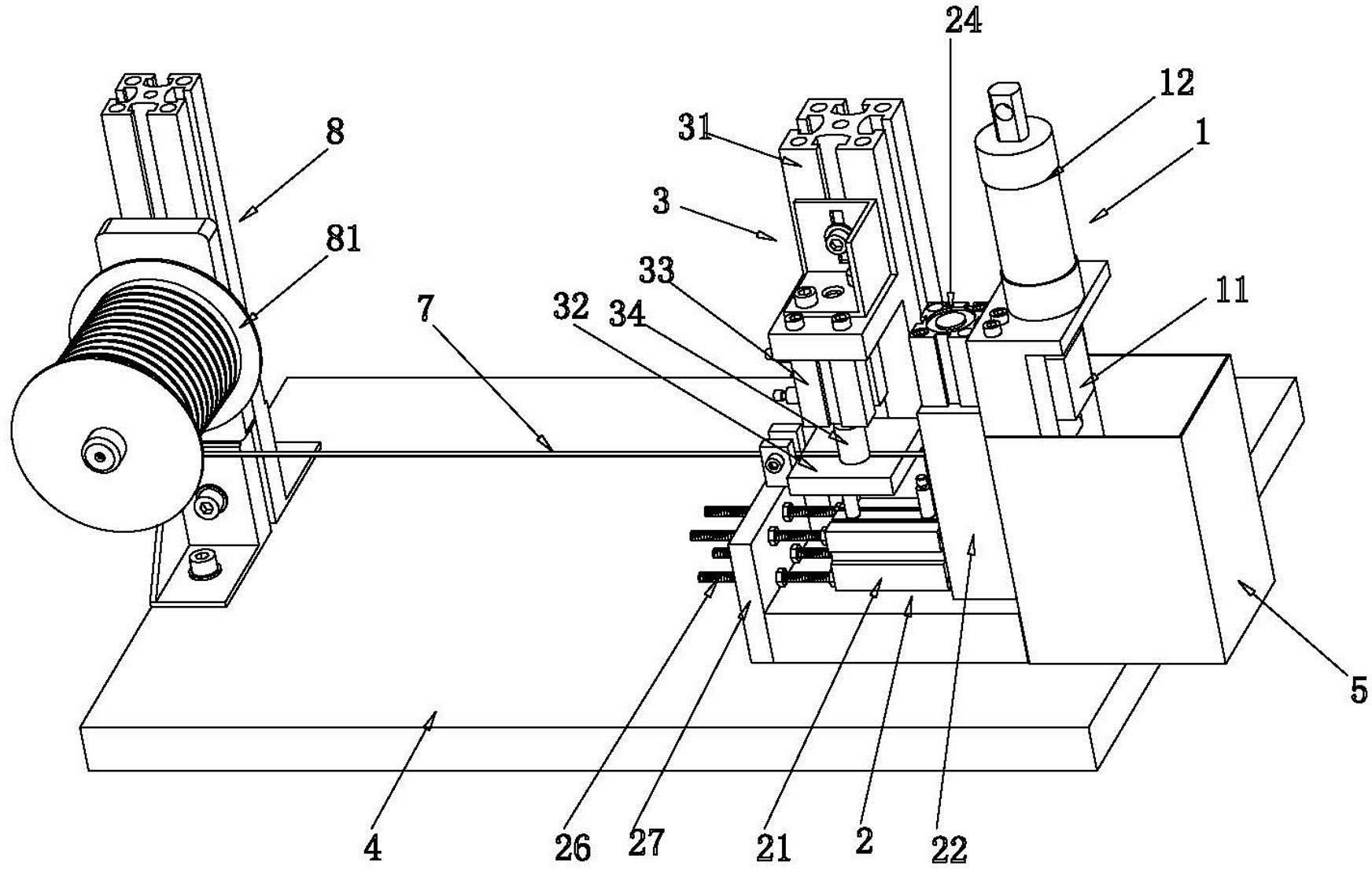

[0013] refer to figure 1 , figure 2 , a fully automatic cutting machine disclosed by the present invention, comprising: a material cutting device 1, a feeding device 2 for transporting a material belt to be cut to the material cutting device 1 and a material belt positioning device 3, the above material cutting device 1, The feeding device 2 and the strip positioning device 3 can be collectively installed on a base 4, and a storage box 5 is installed at the cutting device 1 to collect cut metal sheets 6 or metal strips.

[0014] As shown in the figure, the cutting device 1 includes a cutting knife 11 and a cutting cylinder 12. The cutting knife 11 is installed on the piston rod of the cutting cylinder 12, and the cutting cylinder 12 can drive the cutting knife 11 to cut off the strip. For the cutting action, the cutting knife 11 can be made of high-speed steel to prevent the cutting knife from deforming.

[0015] As shown in the figure, the feeding device 2 includes a feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com