Sewn material detection system of sewing machine

A detection system and sewing machine technology, applied in the direction of sewing machine components, sewing machine control devices, sewing machine thread cutting mechanism, etc., can solve the problems of imperfect and mature automatic cutting technology of sewing machines, affecting production efficiency, and incorrect timing of thread cutting, etc. , to achieve the effect of automatic cutting and trimming, improving productivity and production quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

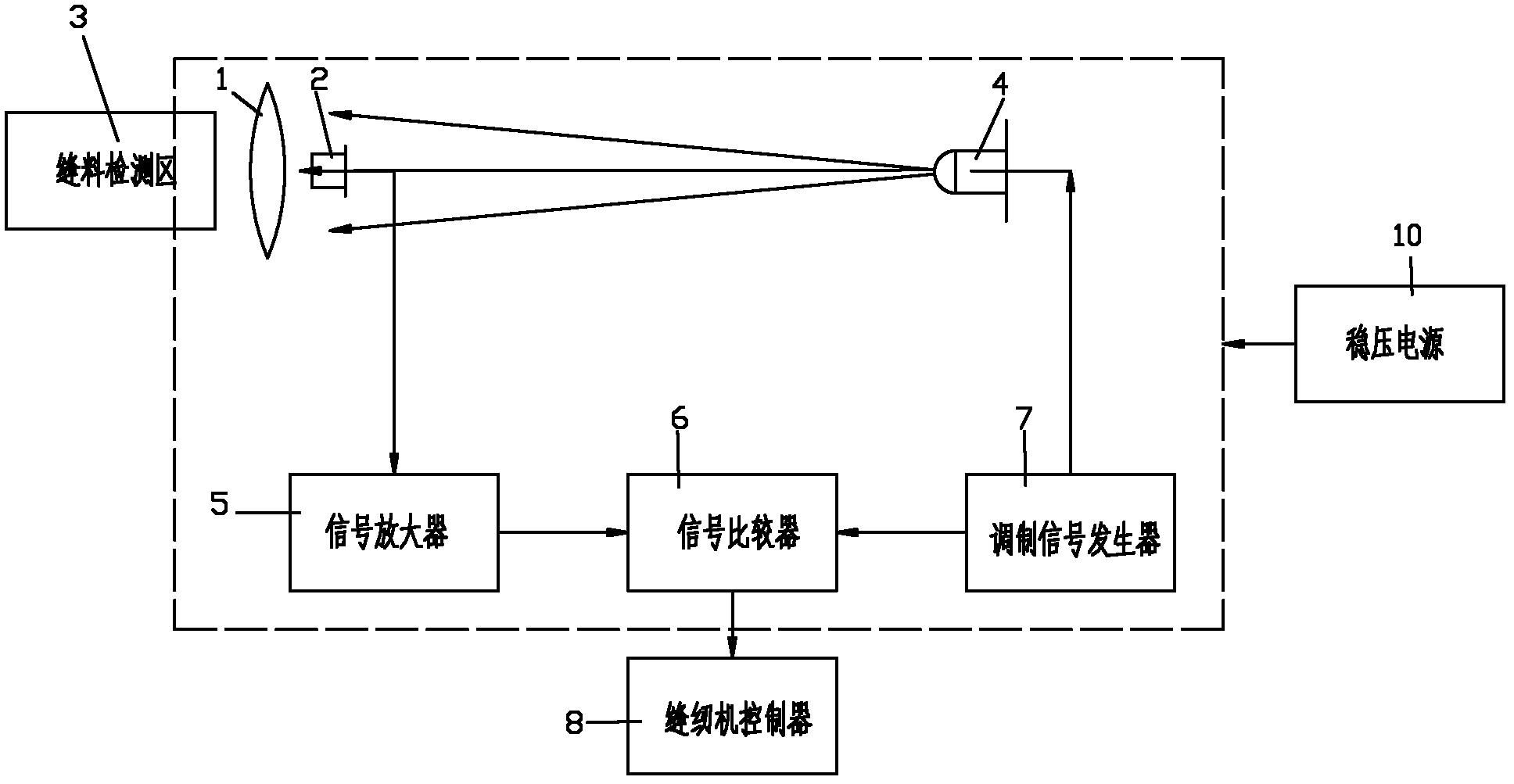

[0016] Such as figure 1 As shown, the present invention includes a sewing machine controller 8, a detection device connected to the sewing machine controller 8, and a stabilized power supply 10 that is connected to the detection device and the sewing machine controller 8 respectively and supplies power to the two; The detection device includes a modulation signal generator 7, a transmitter 4 that emits the modulated light output by the modulation signal generator 7, a photosensitive element 2 arranged in parallel in the projection direction of the transmitter 4, and a photosensitive element 2 arranged in parallel on the left side of the photosensitive element 2. The above-mentioned modulated light converges to the lens group 1 of the seam detection area 3, the signal amplifier 5 that amplifies the electrical signal converted from the light reflected by the seam detection area 3 output by the photosensitive element 2, and the signal amplifier 5 outputs The signal of the signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com