Test tube cover and bacteria blocking membrane automatic membrane pasting and welding device

A technology of welding device and test tube cover, which is applied in the field of test tube cover antibacterial film automatic film welding device, which can solve the problems of low welding efficiency and low work efficiency of antibacterial film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following is attached Figure 1-11 The application is described in further detail.

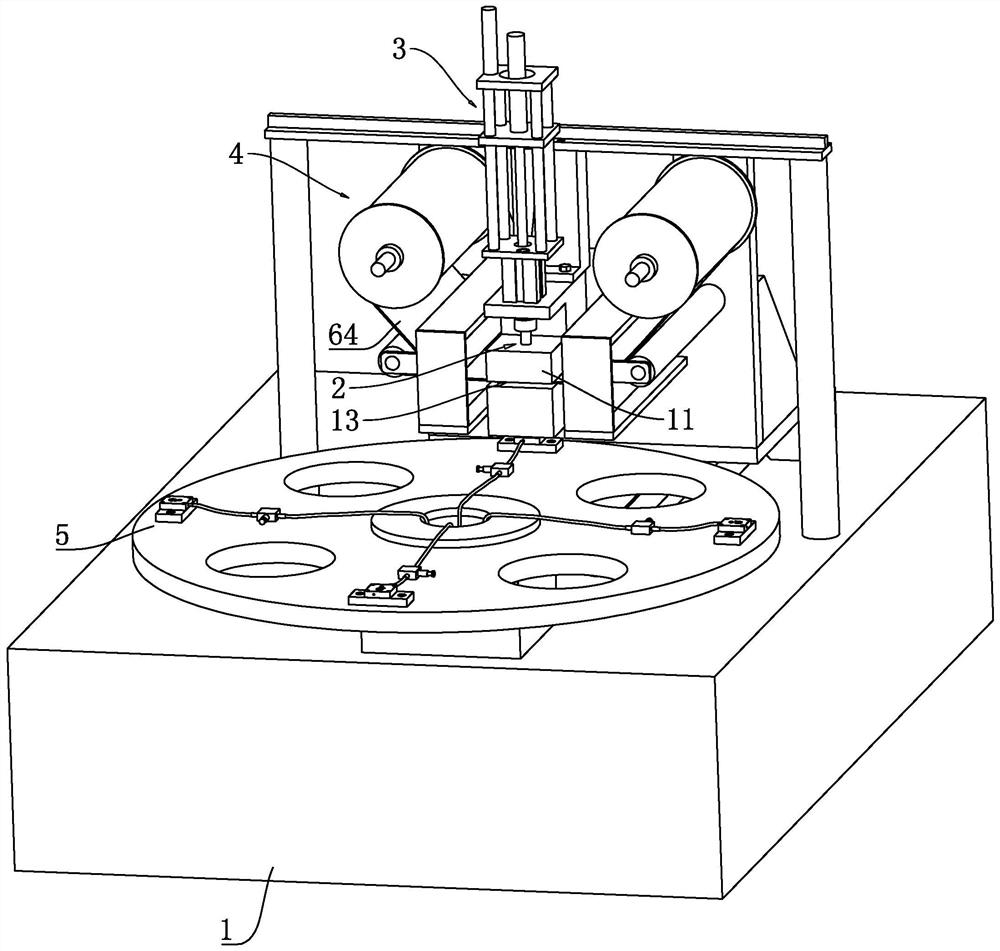

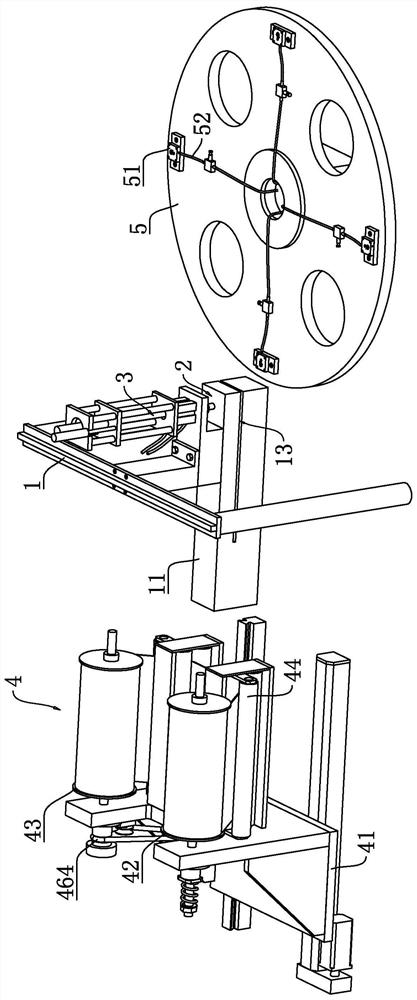

[0055] The embodiment of the present application discloses a test tube cap antibacterial film automatic film welding device. refer to figure 2 , a test tube lid antibacterial film automatic film welding device, including a frame 1, a turntable 5, a punching mechanism 2, a film transfer mechanism 3 and a film feeding mechanism 4. The turntable 5 is rotatably arranged on the frame 1 , on which a bearing platform 11 is fixed, and the punching mechanism 2 and the film transfer mechanism 3 are both installed on the bearing platform 11 . The film feeding mechanism 4 is slidably arranged on the frame 1 , and the antibacterial film 64 is wound on the film feeding mechanism 4 .

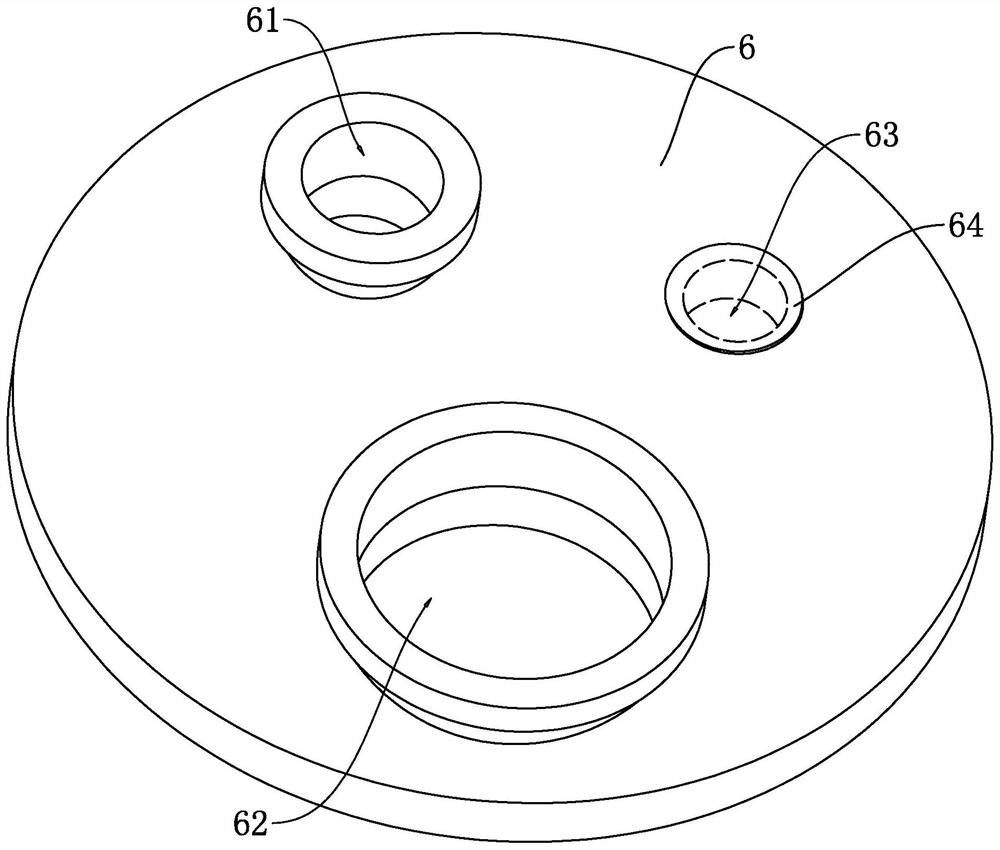

[0056] refer to image 3 with Figure 4 , a number of positioning fixtures 51 are fixed on the turntable 5 , and the number of positioning fixtures 51 are evenly distributed on the edge of the turntable 5 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com