Heightened lug-free armrest support and bending forming method thereof

A handrail support, bending forming technology, applied in metal processing, escalator, metal processing equipment and other directions, can solve the problems of thinning thickness, inability to continuously process, many surface scars, etc., to achieve no burrs, constant thickness, and reduced process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

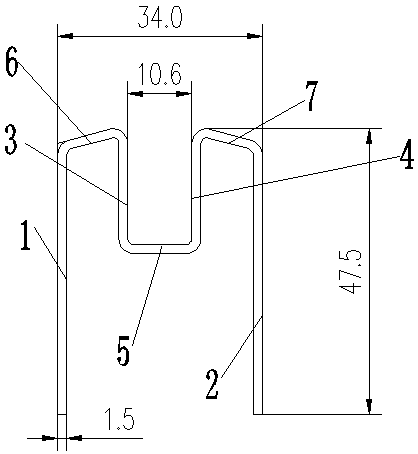

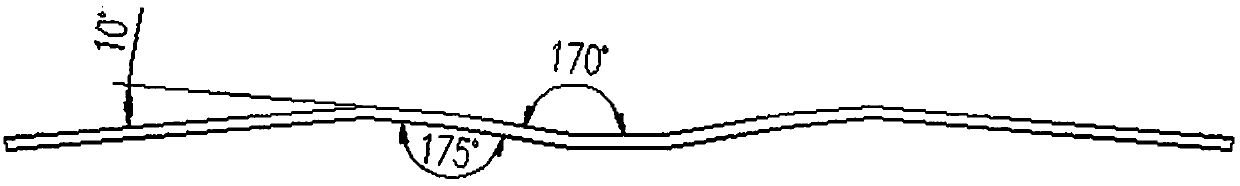

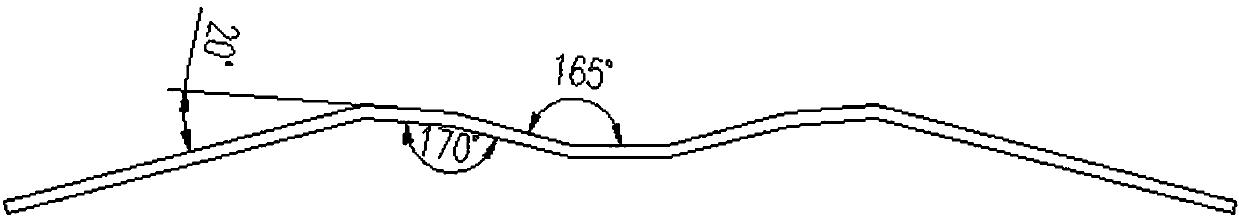

[0028] Such as Figure 1-7 As shown, the present invention is a raised armrest bracket without ears, and the bracket includes a first side wall 1 and a second side wall 2, between which there are also respectively A third side wall 3 and a fourth side wall 4 are provided, the third side wall 3 and the fourth side wall 4 are connected by a straight plate 5, the length of the third side wall and the fourth side wall is 19.25-19.75mm, It is preferably 19.25mm, the first side wall 1 and the third side wall 3 are connected by the first inclined side wall 6, and the second side wall 2 and the fourth side wall 4 are connected by the first inclined side wall Two inclined si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com