High-voltage transistor and manufacturing method thereof

A technology of high-voltage transistors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of increasing the thickness of the gate oxide layer, reducing the saturation current, and unfavorable conductive channel formation. The effect of increasing the breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] The core idea of the present invention is that the first oxide layer and the second oxide layer can have different Thickness, while increasing the thickness of the first oxide layer to increase the breakdown voltage, keep the thickness of the second oxide layer constant so as not to affect the saturation current.

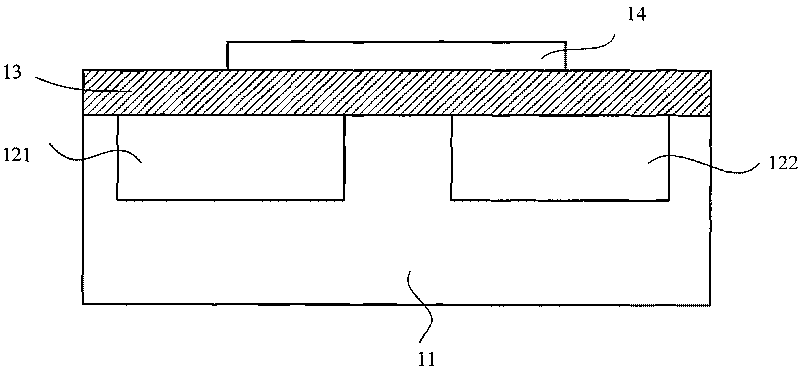

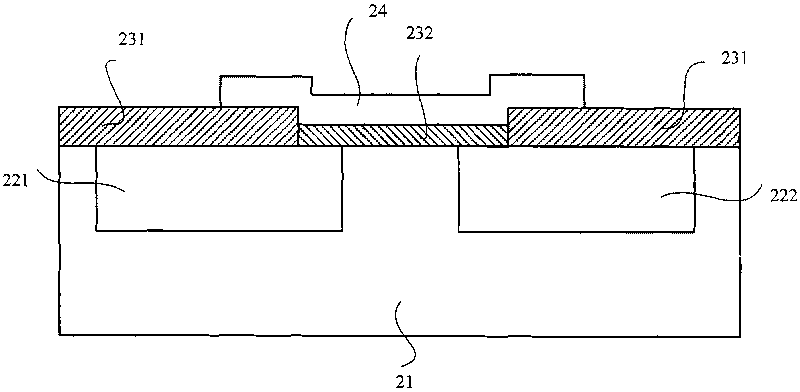

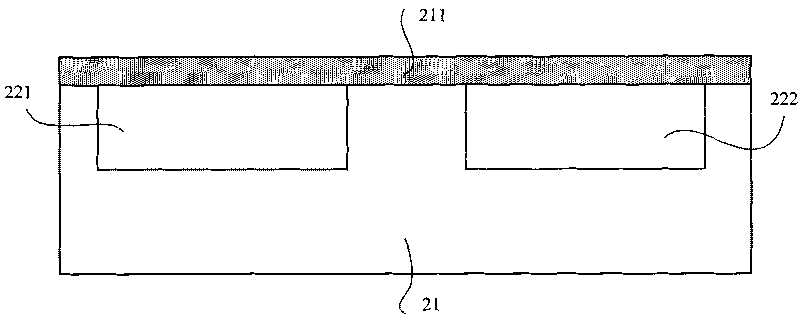

[0026] see figure 2 , figure 2 It is a schematic structural diagram of a high-voltage transistor according to the present invention. figure 2 Among them, the high voltage transistor includes: a high voltage well region 21; a source drift region 221 and a drain drift region 222, both formed in the high voltage well region 21; a first oxide layer 231 formed in the source drift region 221 and on the drain drift region 222...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com