A <111> textured nano-twinned Cu bulk material and its preparation method

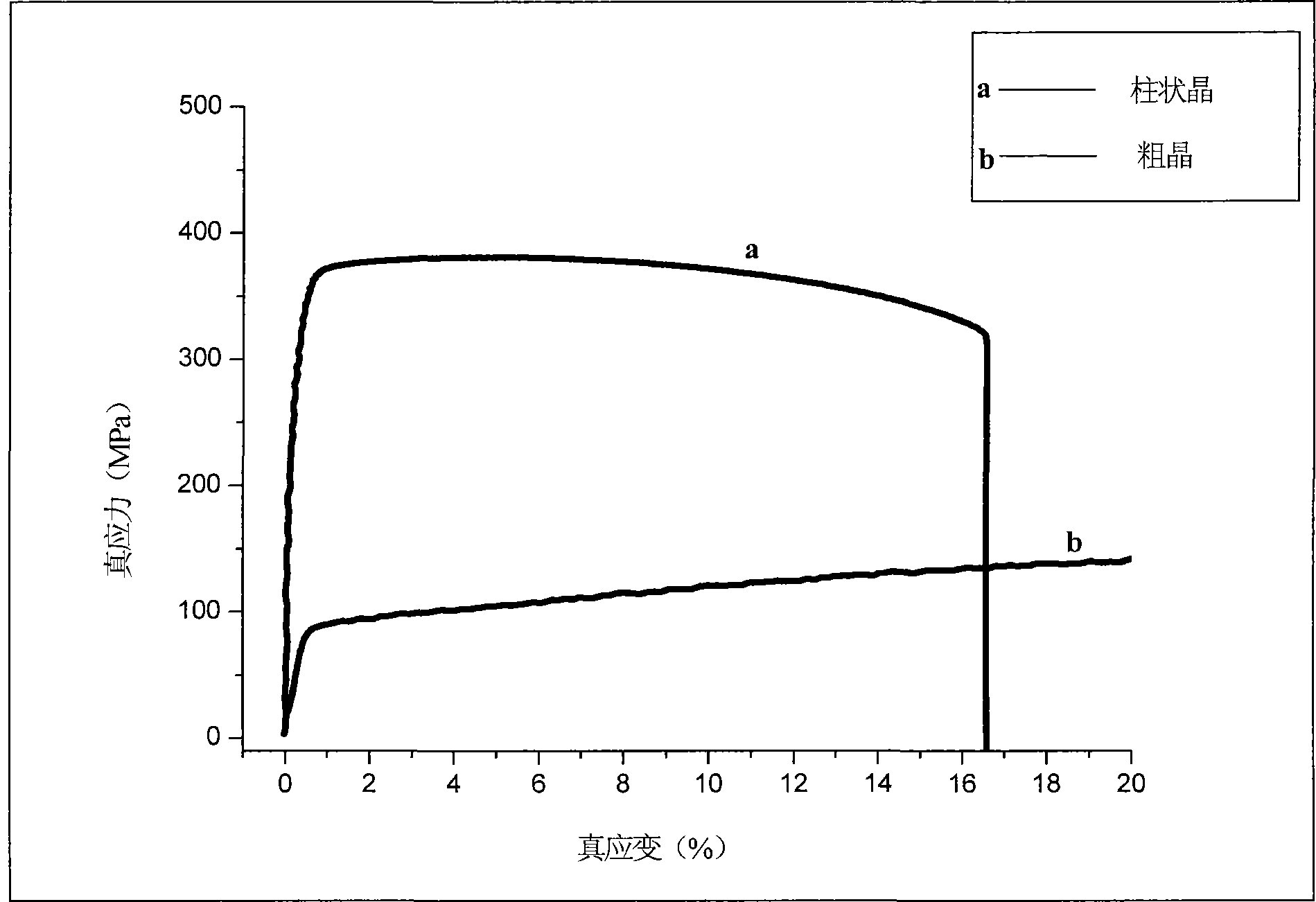

A technology of nano-twinned and bulk materials, applied in the field of textured nano-twinned Cu bulk materials and its preparation, high-strength nano-twinned structure copper materials and its preparation, can solve the problems of material strength reduction and achieve good plasticity, The effect of high strength and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

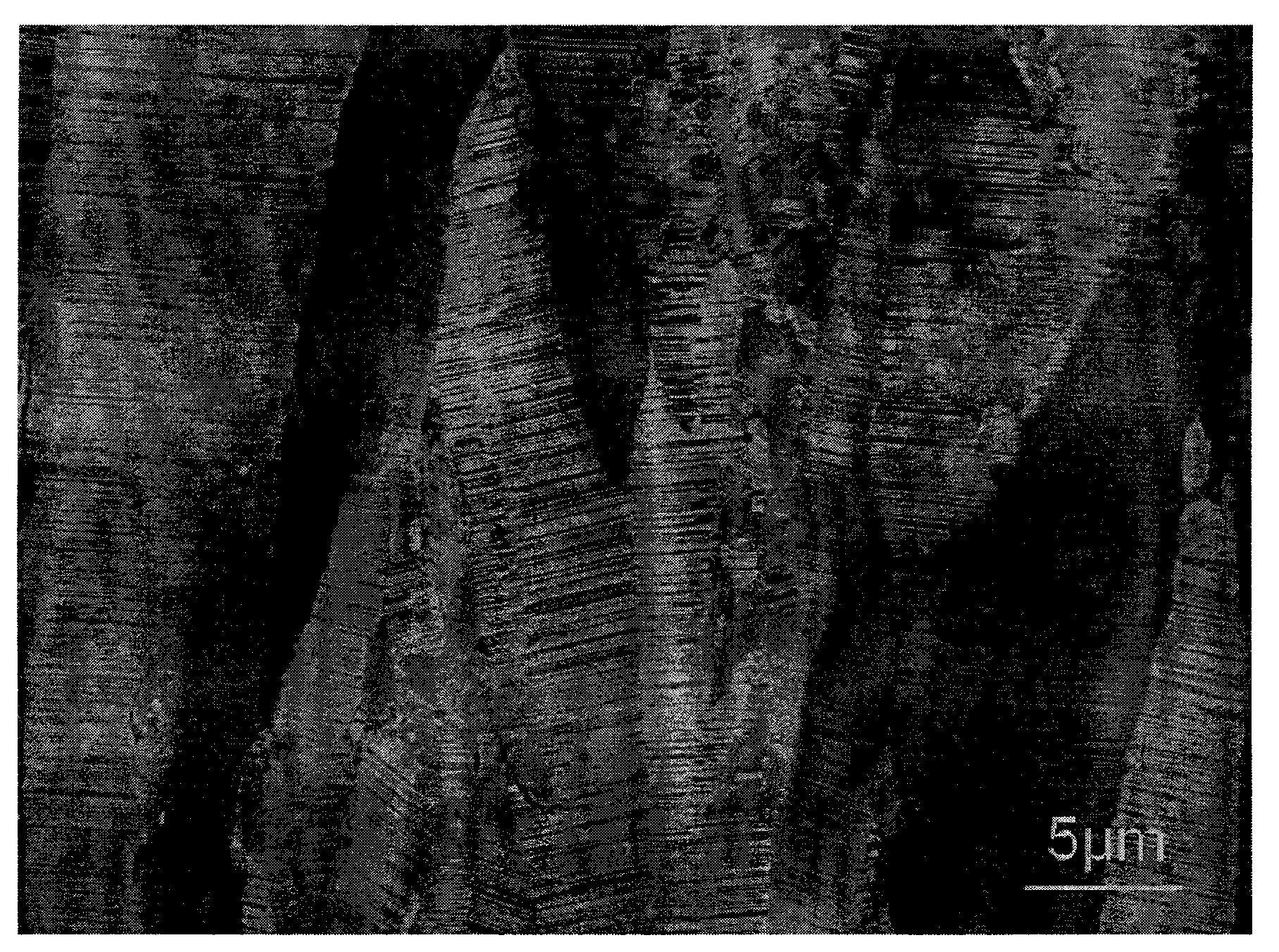

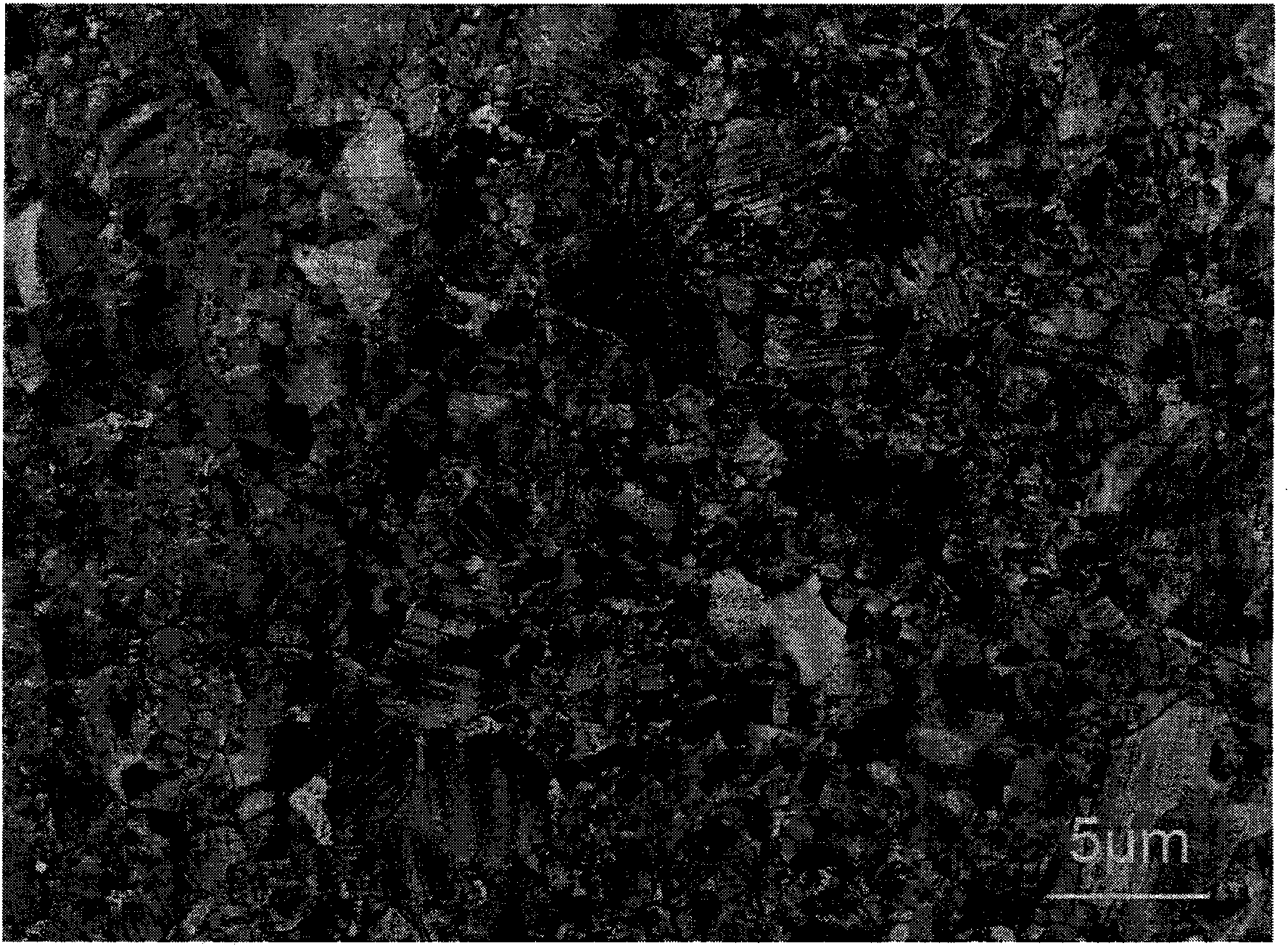

[0038] 1. Preparation of thin flake nanostructured Cu materials by electrolytic deposition

[0039] Electrolytic deposition equipment: DC stabilized voltage and stabilized current power supply;

[0040] Electrolyte requirements for electrolytic deposition: electronically pure CuSO 4 , Strictly control the content of heavy metal impurities in the electrolyte, the water used for distributing the electrolyte is high-purity deionized water (conductivity4 The concentration of the solution is 180g / L, and the acidity of the electrolyte is: pH=1;

[0041] Cathode and anode requirements: the anode is a pure copper plate with a purity higher than 99.99wt%, and the cathode is a pure titanium plate with a mechanically polished surface (industrial pure titanium, purity 99.69wt%).

[0042] In the above CuSO 4 Add the following additives to the solution:

[0043] Gelatin: 10mL / L (per liter of electrolyte), 0.2wt% gelatin aqueous solution;

[0044] High-purity NaCl: 0.5mL / L (per liter of el...

Embodiment 2

[0054] The difference from Example 1 is:

[0055] 1. Preparation of flaky nanostructure Cu materials by electrolytic deposition technology: the electrolyte is used for electronic pure grade high-purity copper sulfate CuSO 4 , add high-purity distilled water (conductivity4 The concentration of the solution is 150g / L, and the acidity is pH=1.0; cathode and anode: the anode is a pure copper plate with a purity higher than 99.99wt%, and the cathode is an iron plate coated with a Ni-P amorphous layer on the surface. The area ratio of the anode and the cathode is is 30:1;

[0056] In the above CuSO 4 Add the following additives to the solution:

[0057] Gelatin: 7.5mL / L (per liter of electrolyte), 0.2wt% gelatin aqueous solution;

[0058] High-purity NaCl: 0.5mL / L (per liter of electrolyte), 10wt% NaCl aqueous solution.

[0059] 2. Electrolysis process parameters: current density is 25.7mA / cm 2 ; The pole distance between the anode and the cathode is 100mm, the area ratio of th...

Embodiment 3

[0063] The difference from Example 1 is:

[0064] 1. Preparation of flaky nanostructure Cu materials by electrolytic deposition technology: electronically pure copper sulfate CuSO for electrolyte 4 , CuSO 4 The concentration of the solution is 200g / L, add high-purity distilled water (conductivity<0.1μm / cm), and the acidity is pH=1.1; cathode and anode: the anode is a pure copper plate with a purity higher than 99.99wt%, and the cathode is coated with Ni on the surface -Low carbon steel plate with P amorphous layer, the area ratio of anode and cathode is 10:1;

[0065] In the above CuSO 4 Add the following additives to the solution:

[0066] Gelatin: 5mL / L (per liter of electrolyte), 0.2wt% gelatin aqueous solution;

[0067] High-purity NaCl: 0.5mL / L (per liter of electrolyte), 10wt% NaCl aqueous solution.

[0068] 2. Electrolysis process parameters: current density is 17.1A / cm 2 , the electrolysis temperature is 18°C, the electrolyte is stirred by circulating water, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com