Patents

Literature

30results about How to "Increased yield strength at room temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

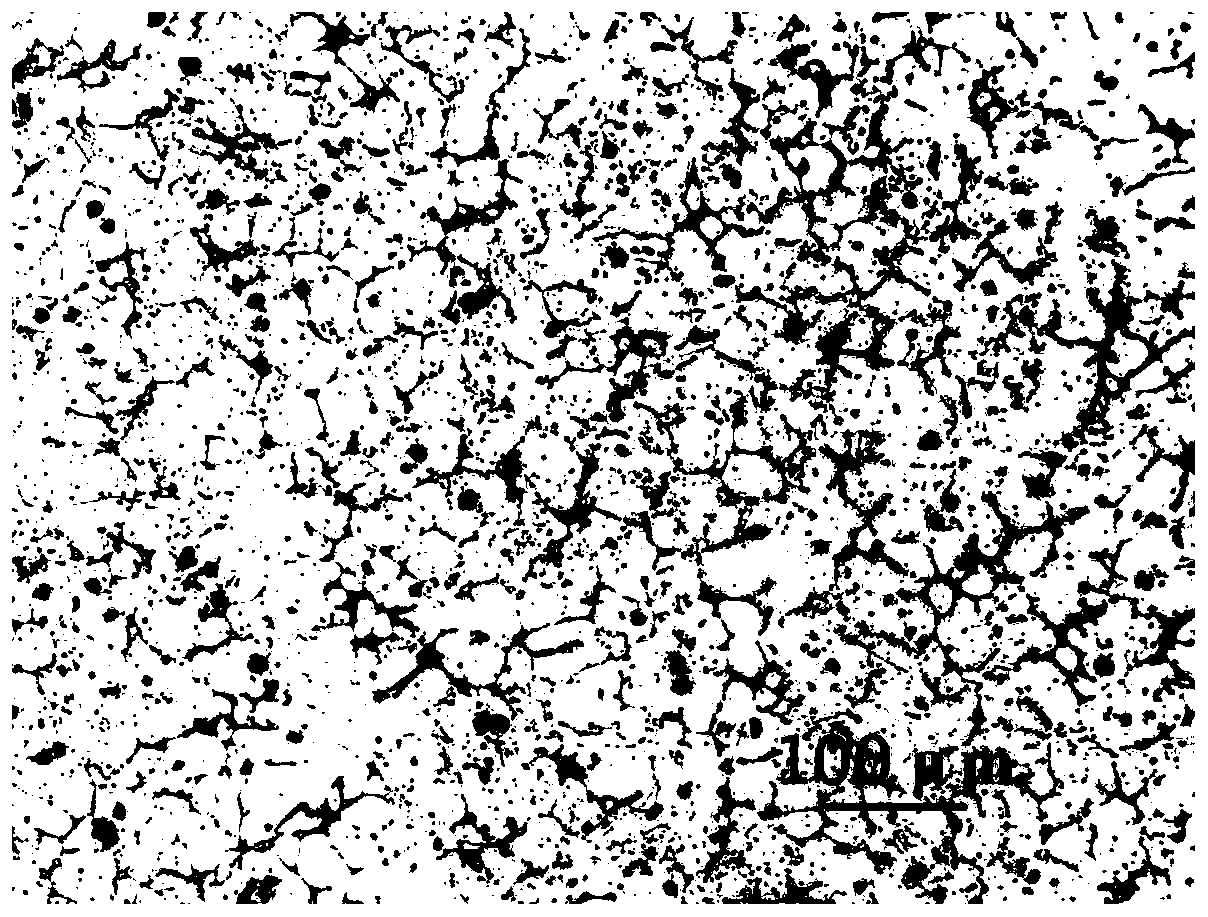

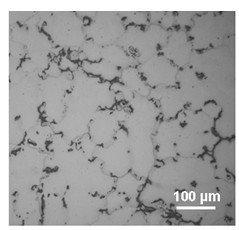

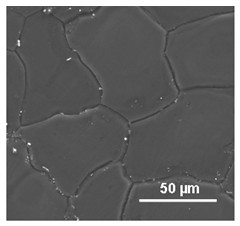

Nano twin crystal copper material with ultrahigh strength and superhigh conductivity as well as preparation method

ActiveCN1498987AImprove propertiesUnique microstructurePhotography auxillary processesProcess efficiency improvementElectrical resistance and conductanceCrystal twinning

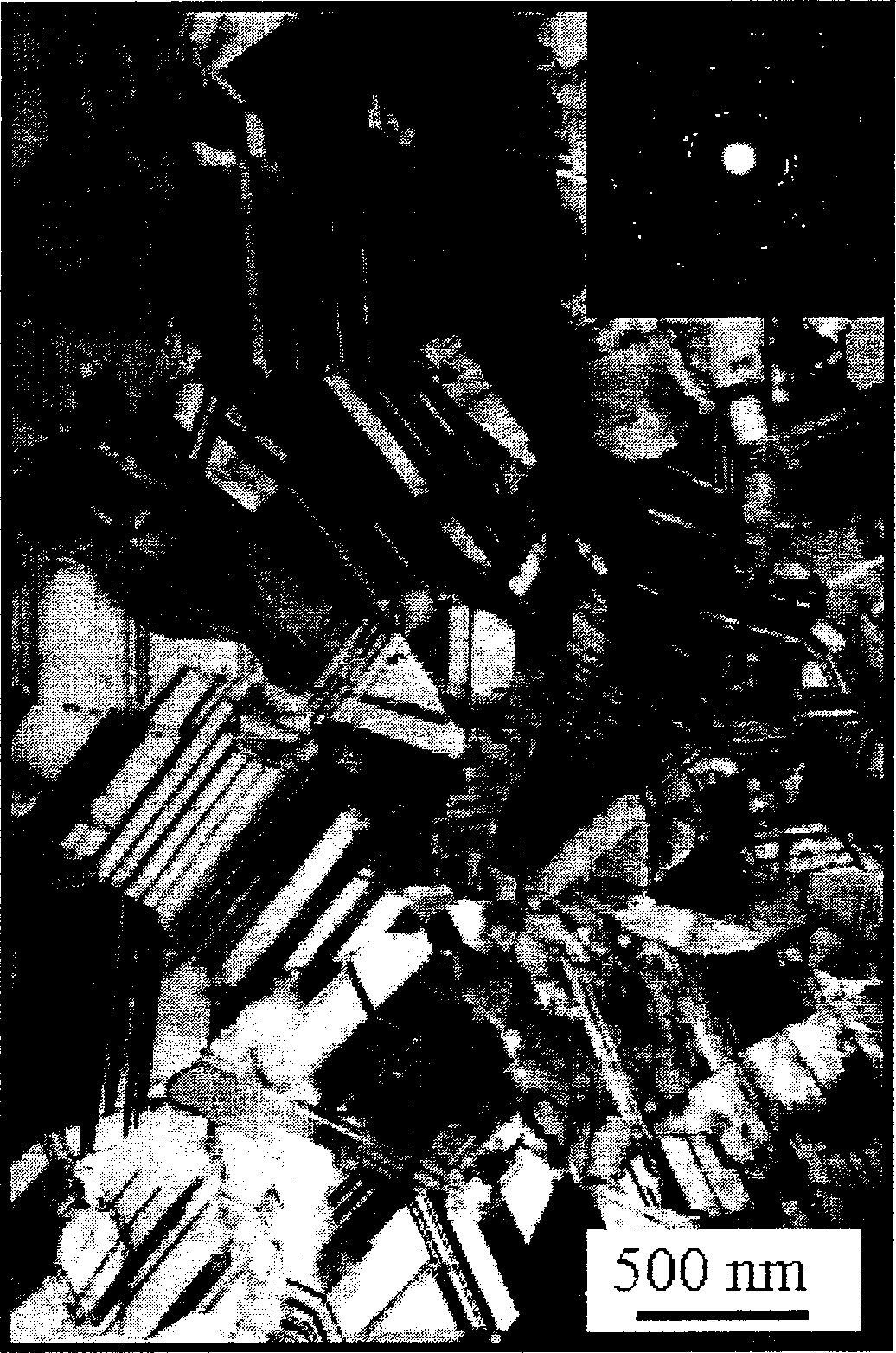

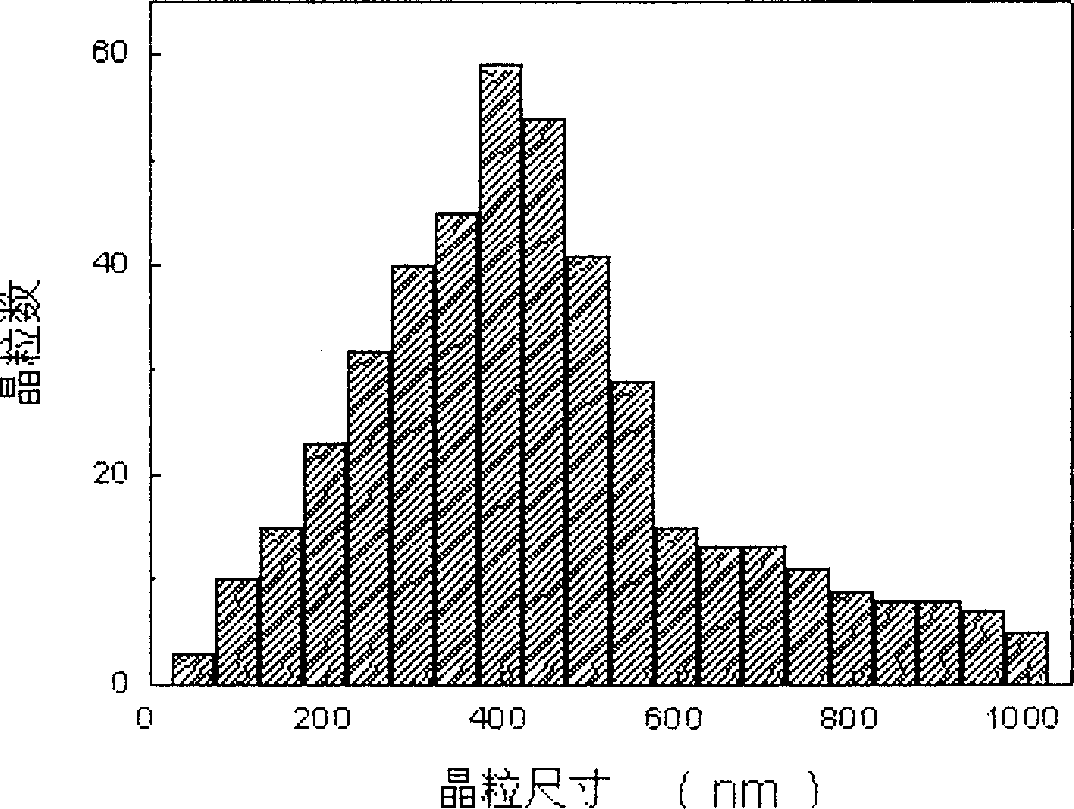

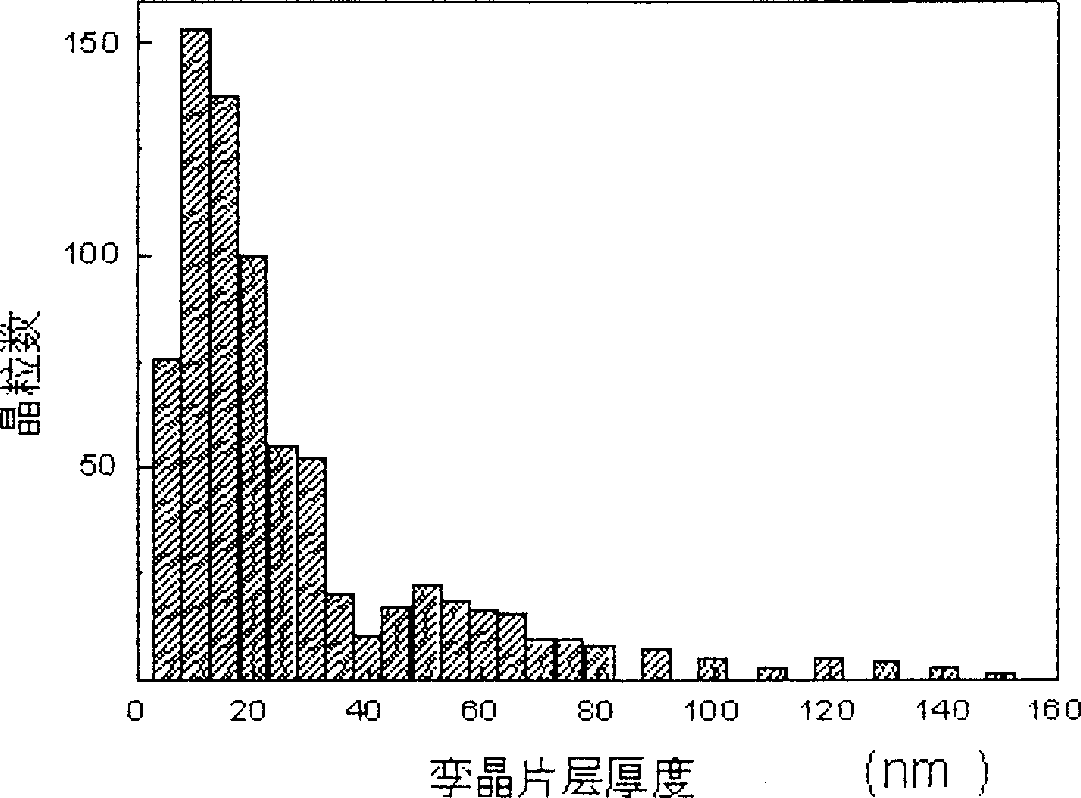

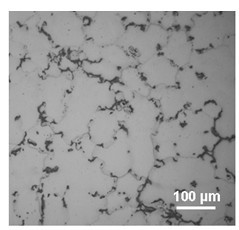

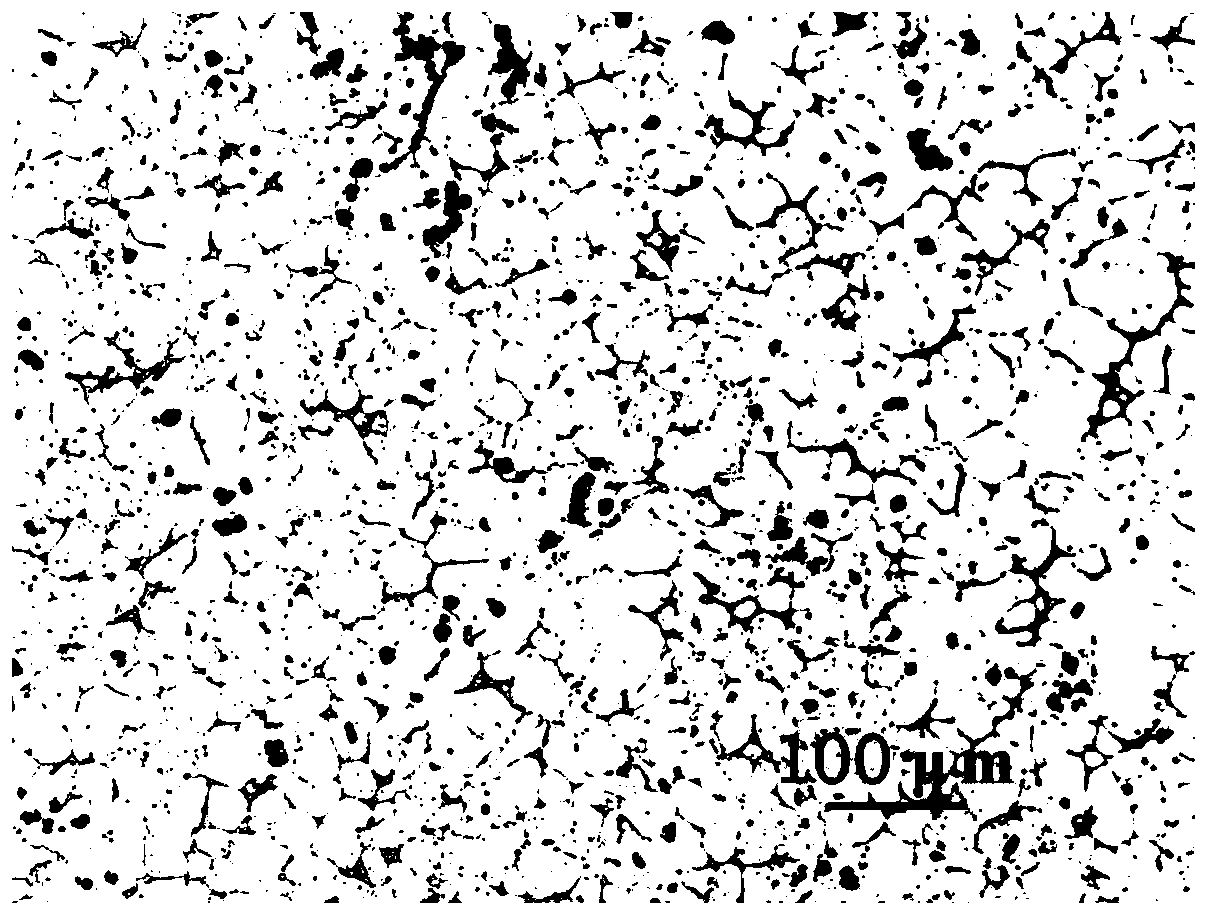

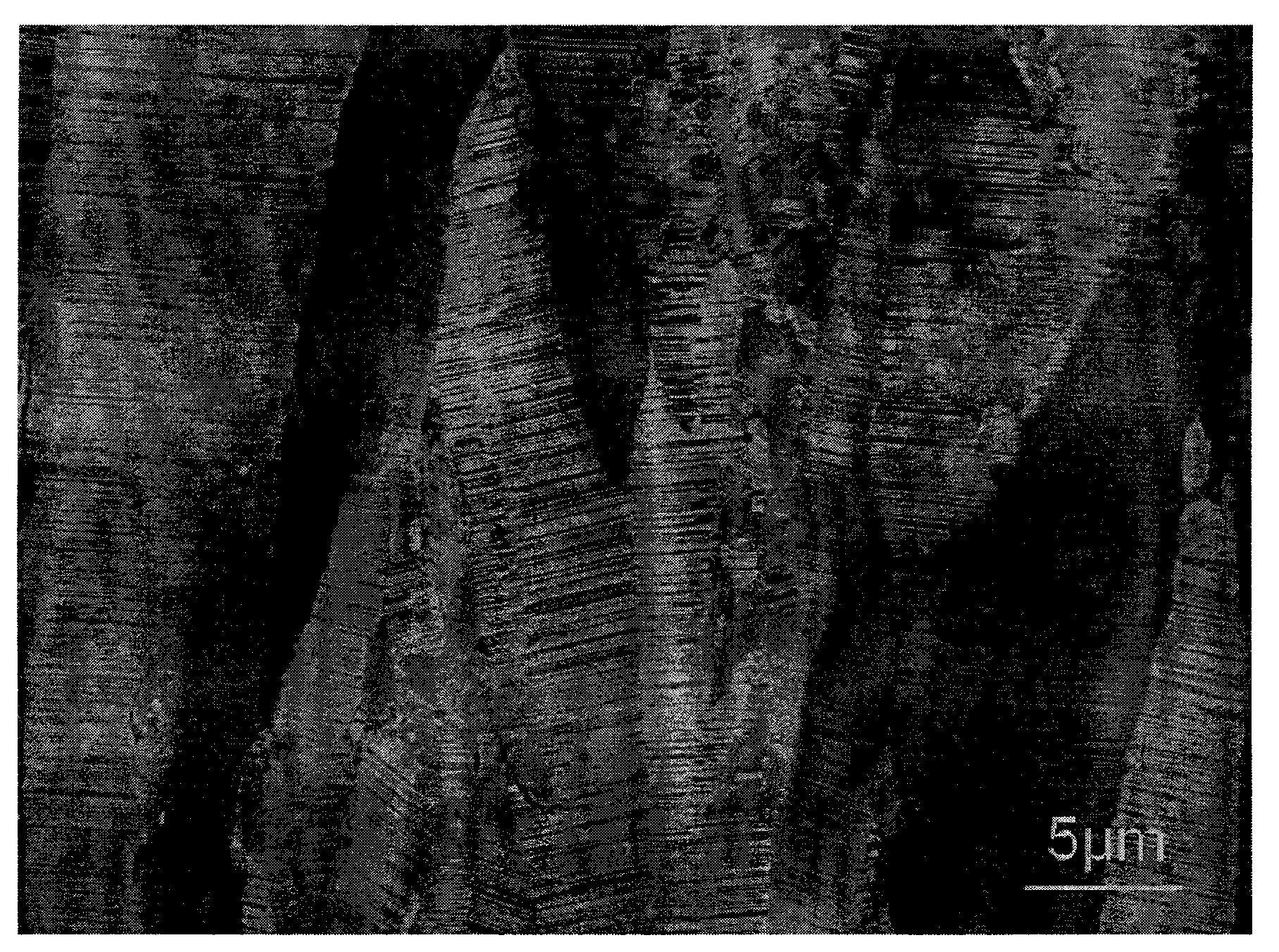

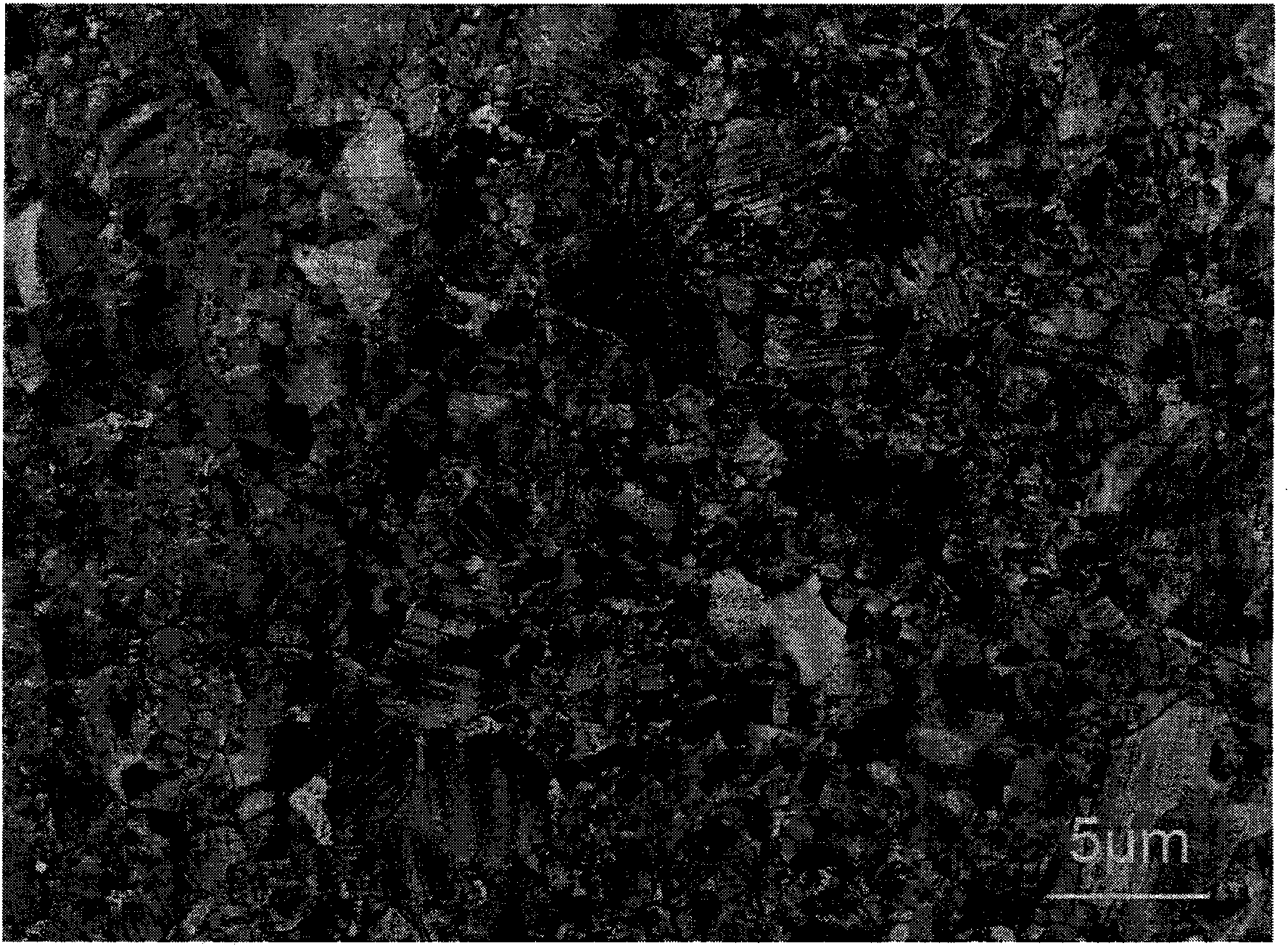

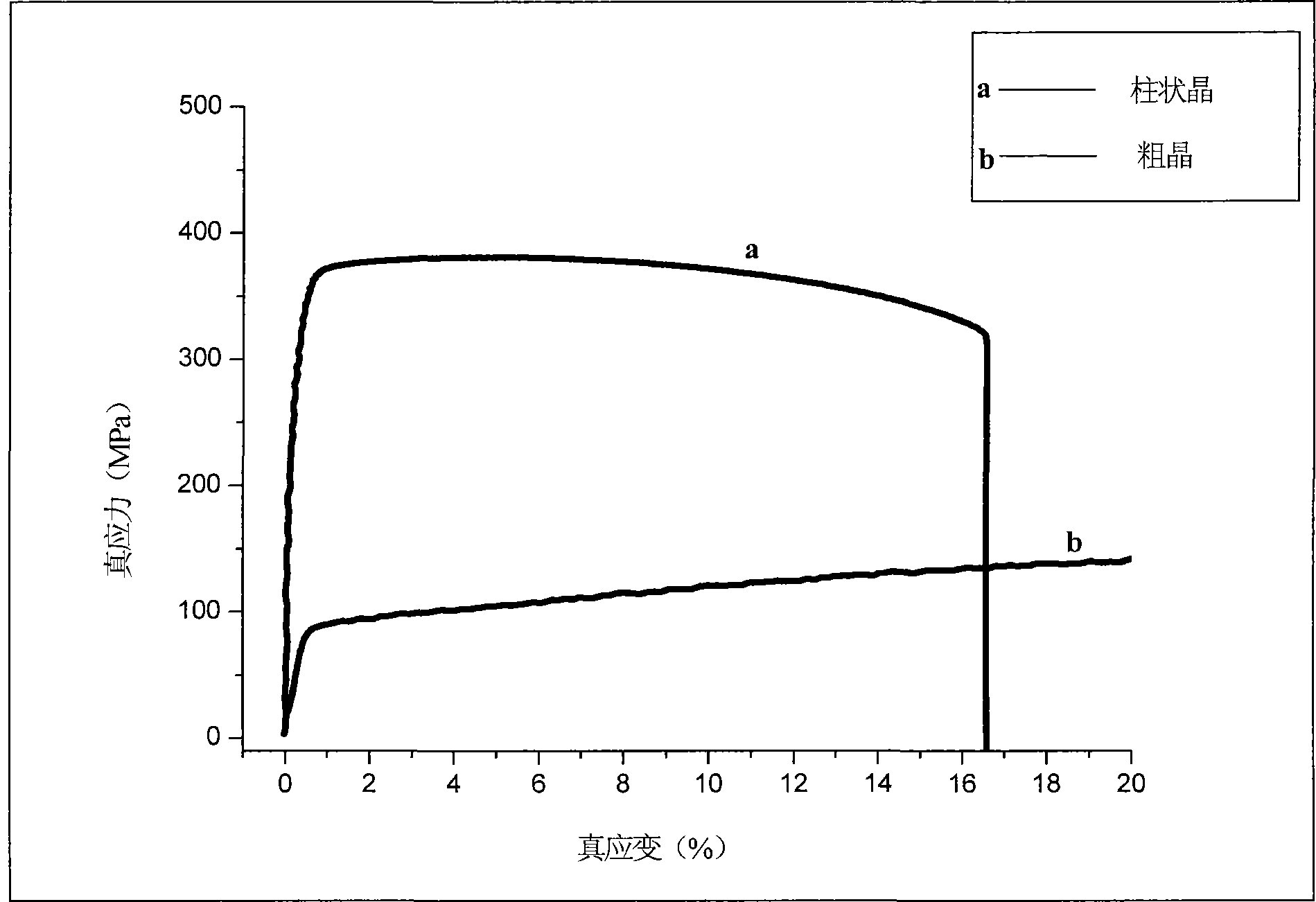

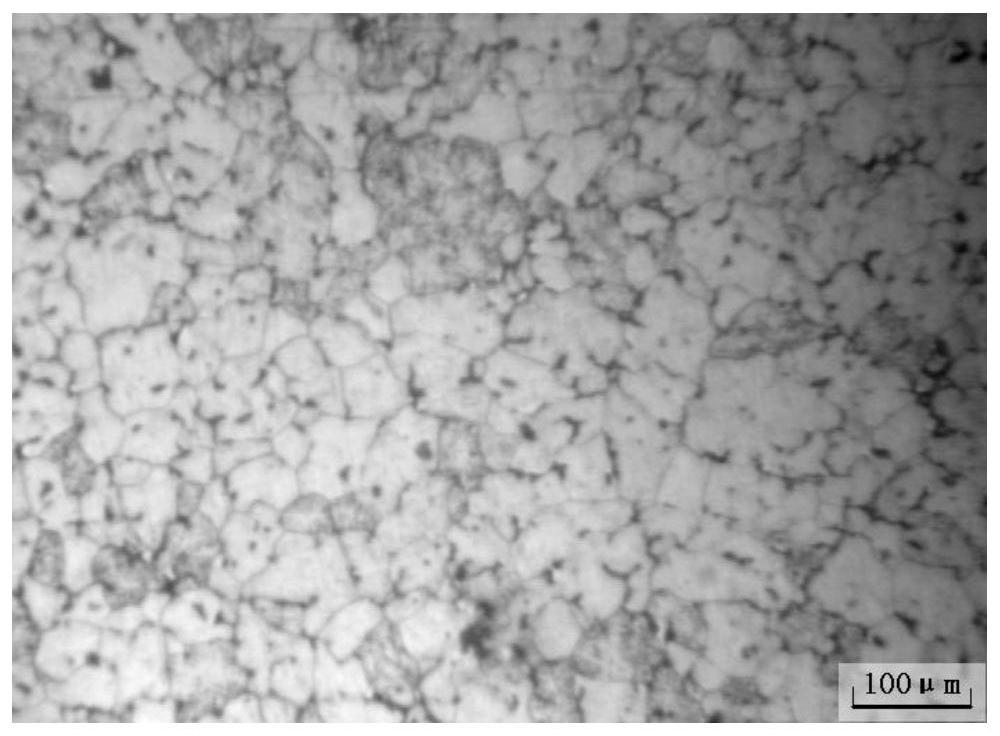

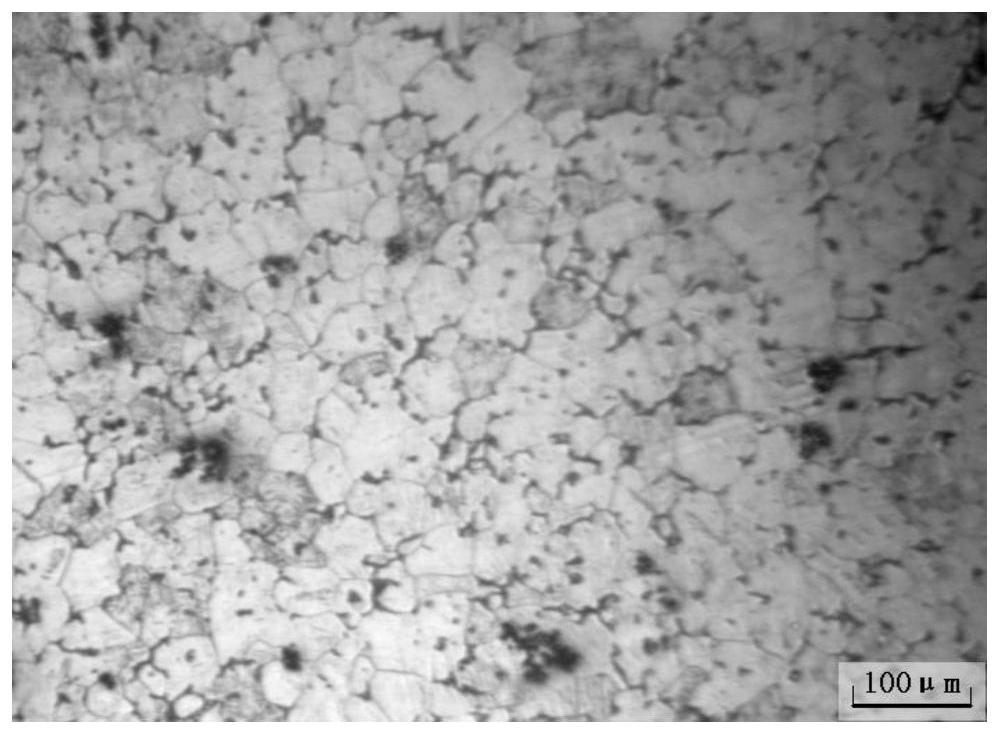

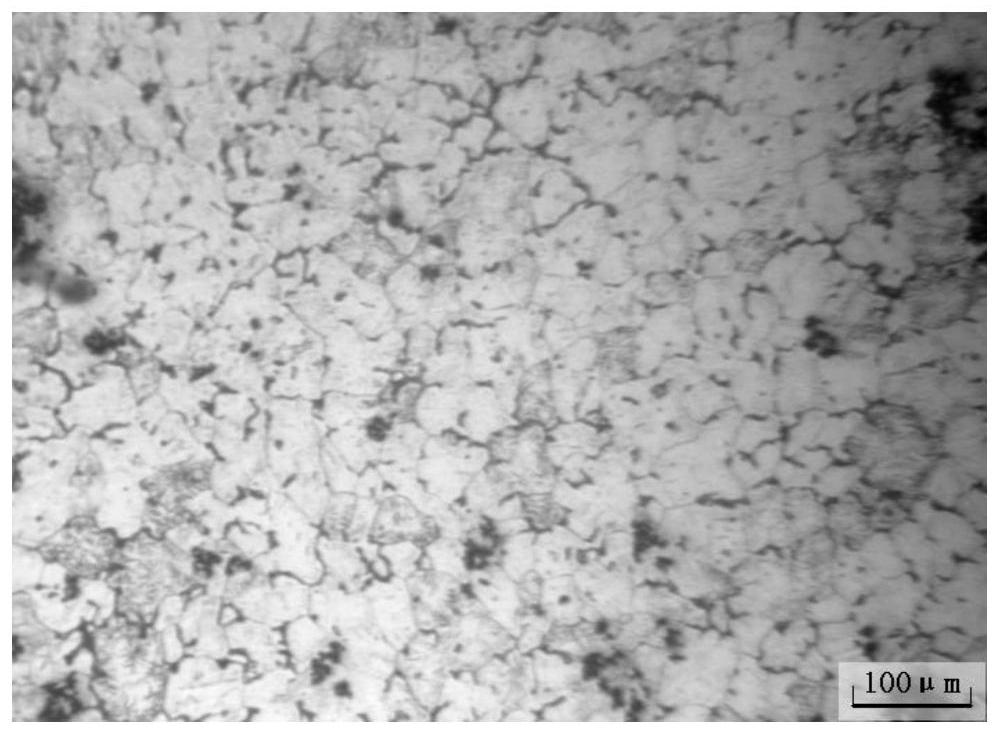

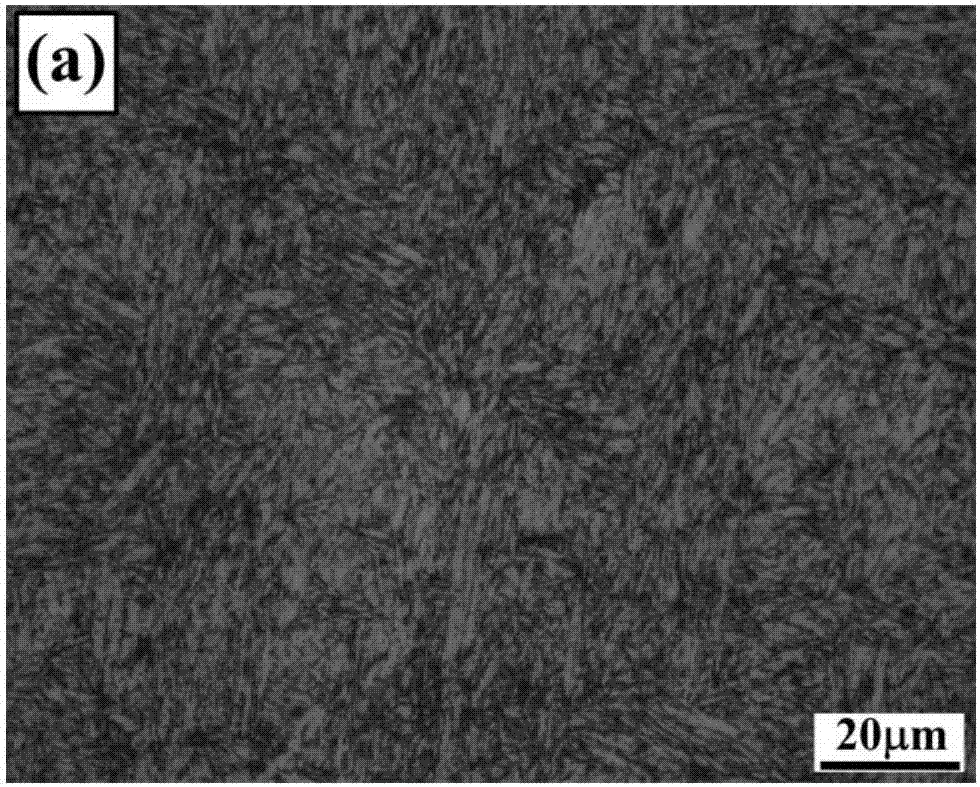

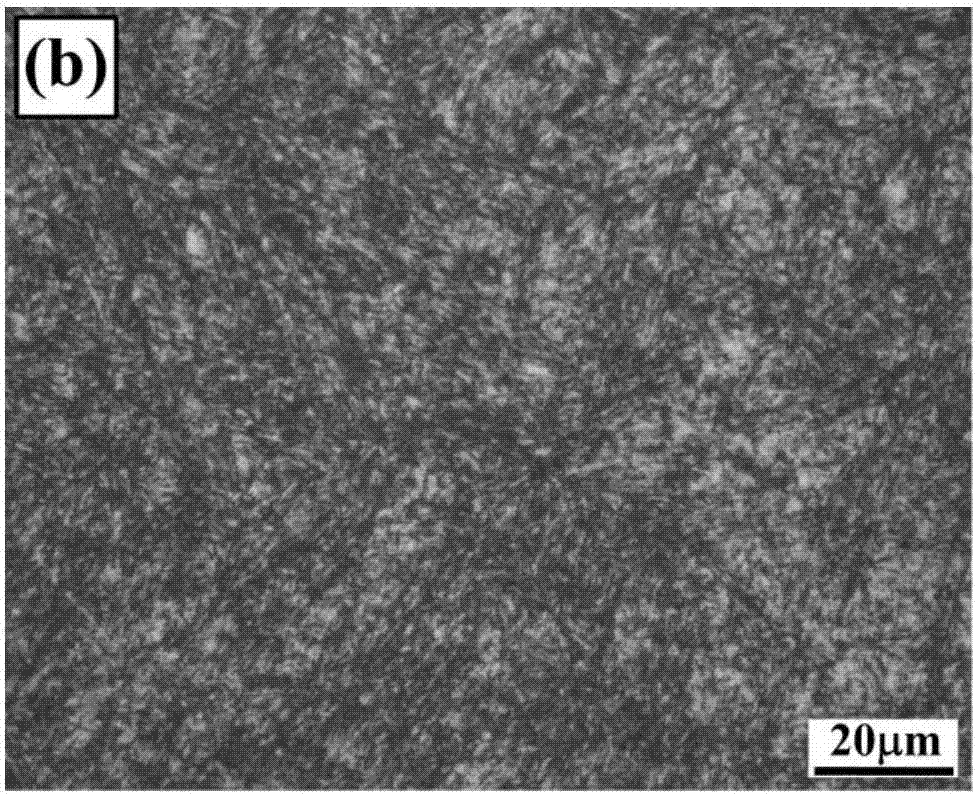

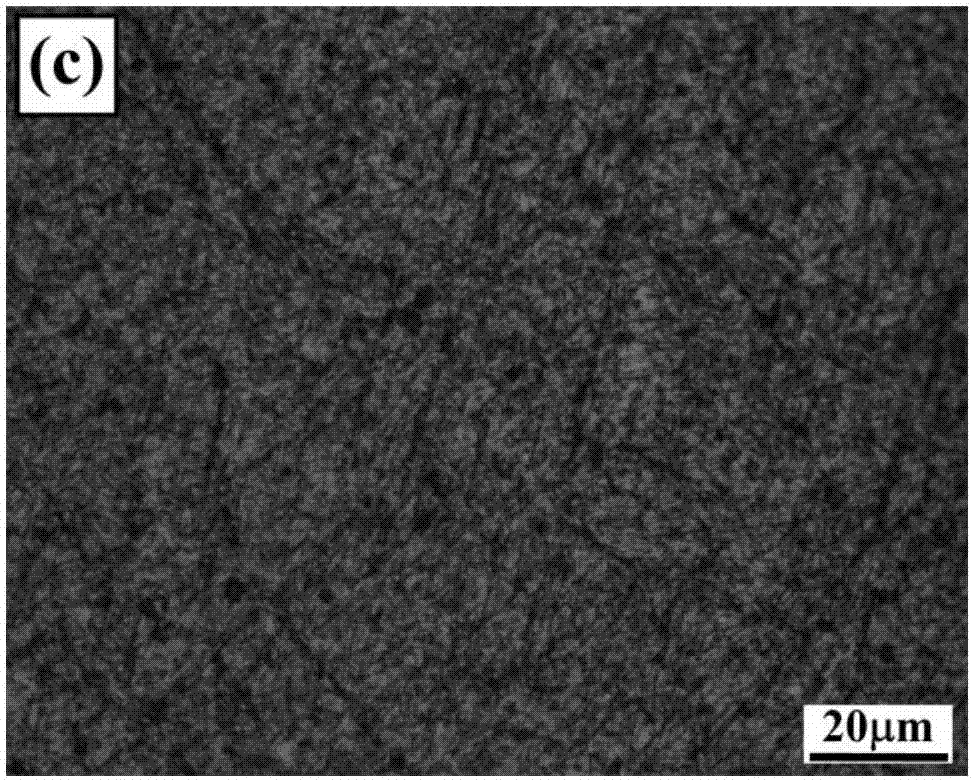

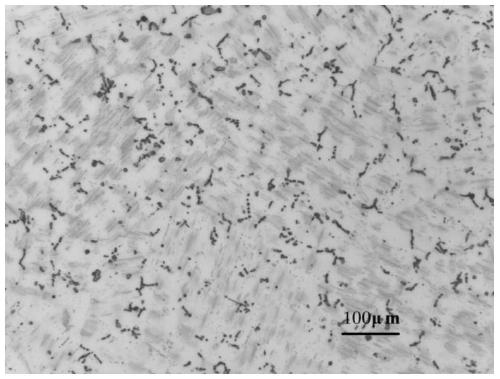

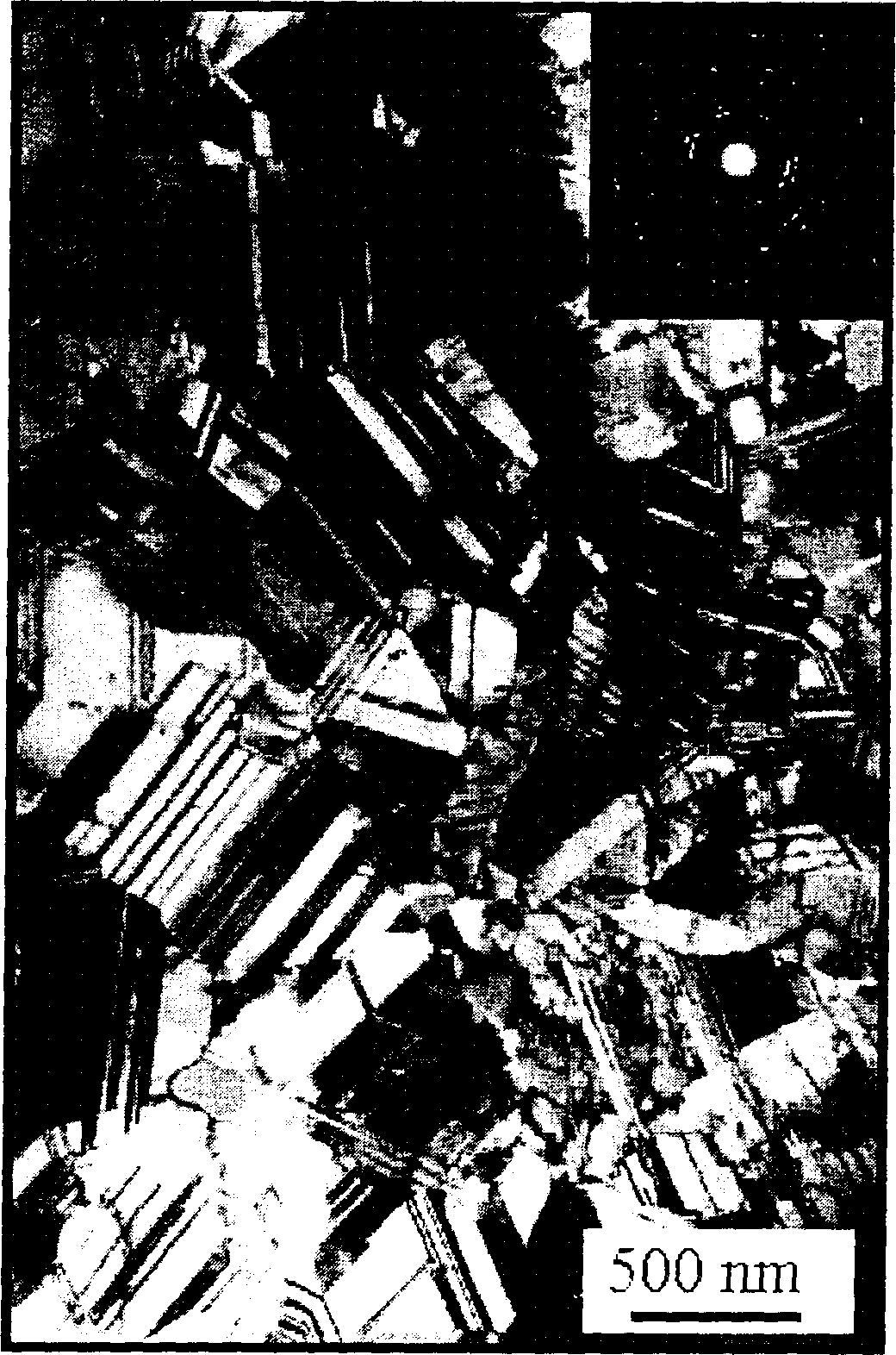

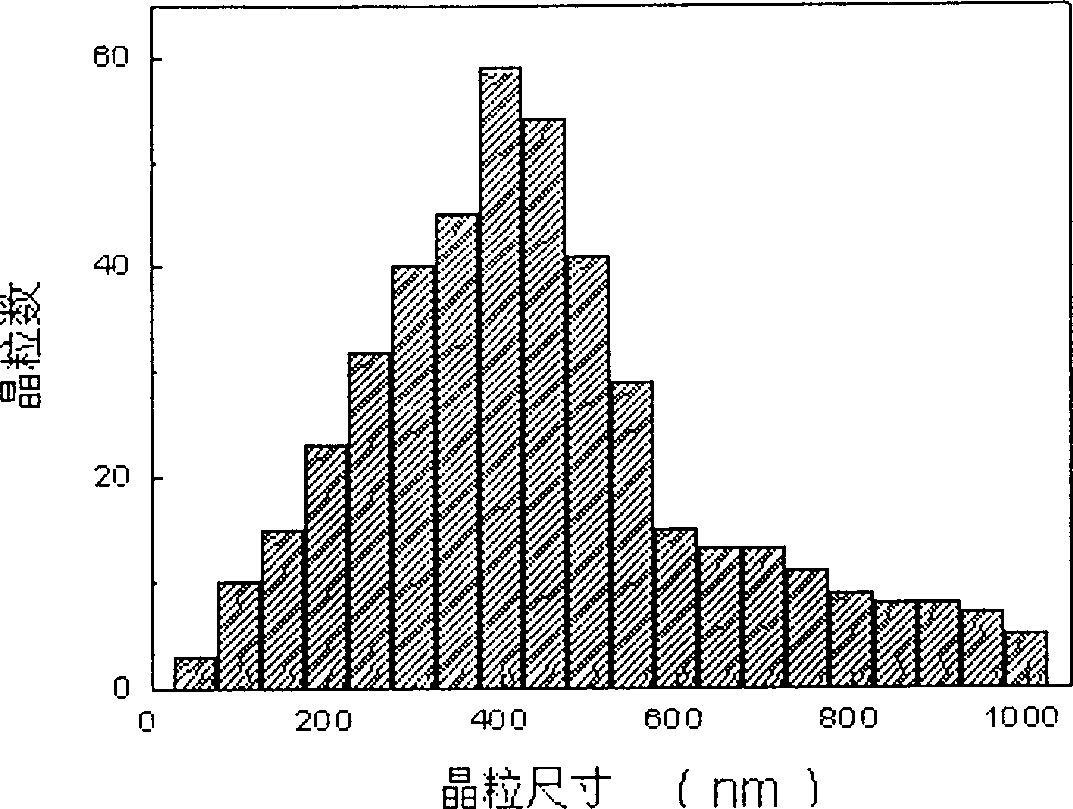

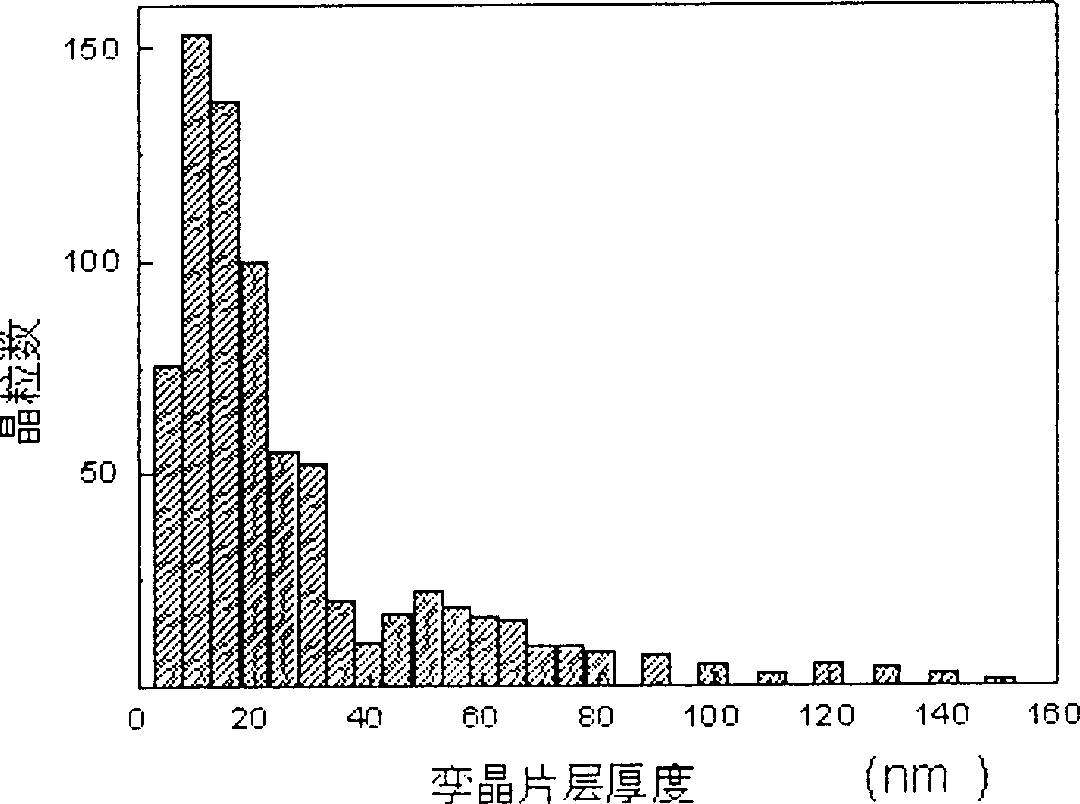

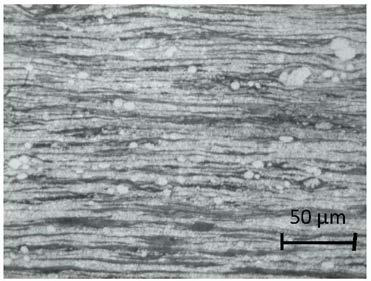

A nano-class twin-crystal copper material with ultrahigh strength and ultrahigh electric conductivity is prepared by electrolytic deposition technique. The resultant high-purity polycrystal copper material features that its microstructure is composed of nearly equiaxed submicron (300-1000 nm) crystals, and in the crystal there are high-density parallel twin crystal layers with different orientations. Its advantages are high yield strength up to 900 MPa and break strength up to 1086 MPa, and high electric conductivity (1.75+ / - 0.02 X to the power -8 ohm.m).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

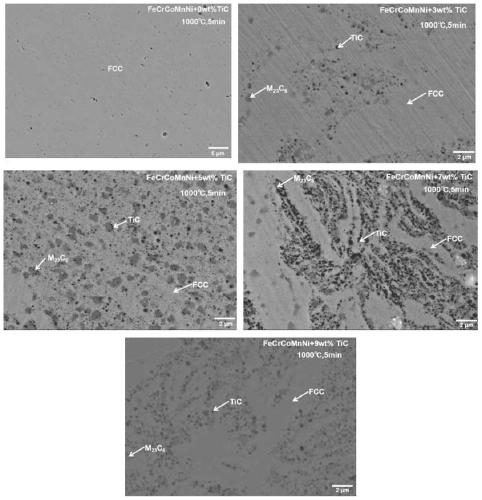

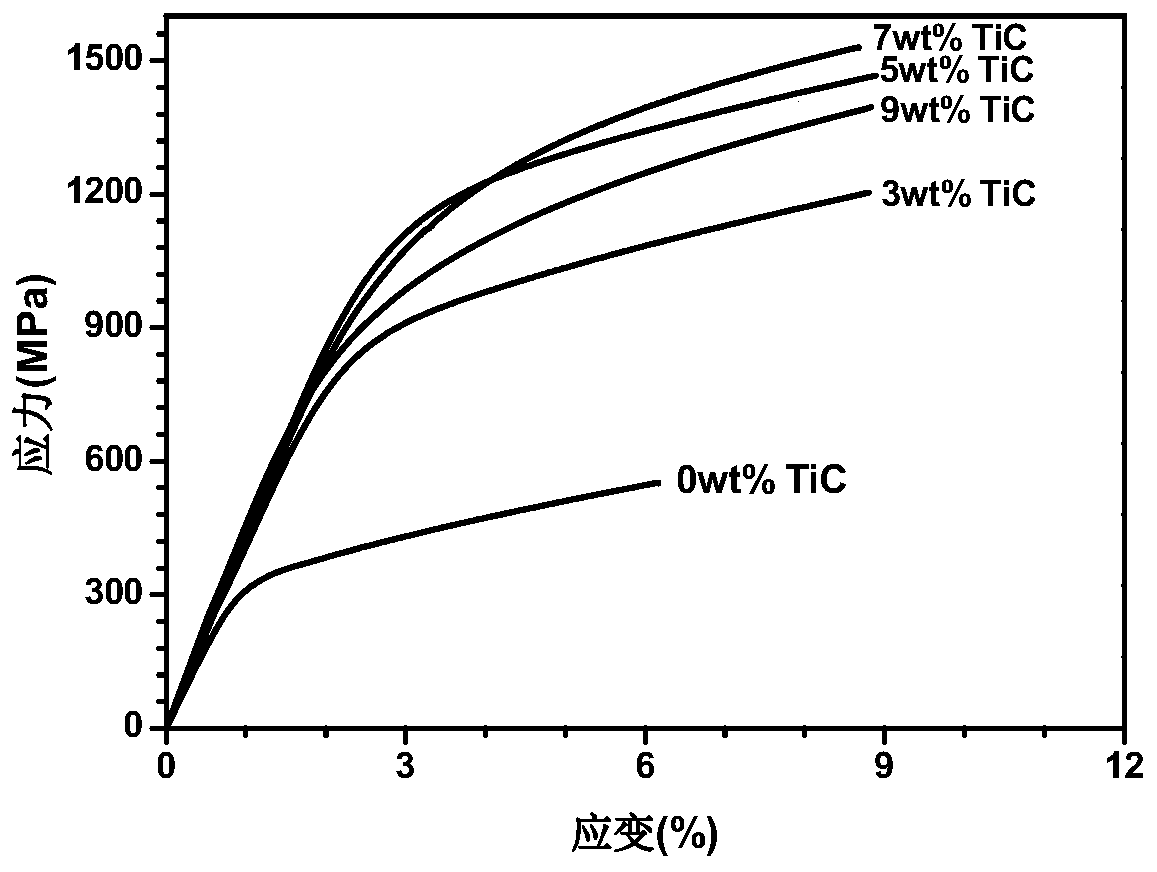

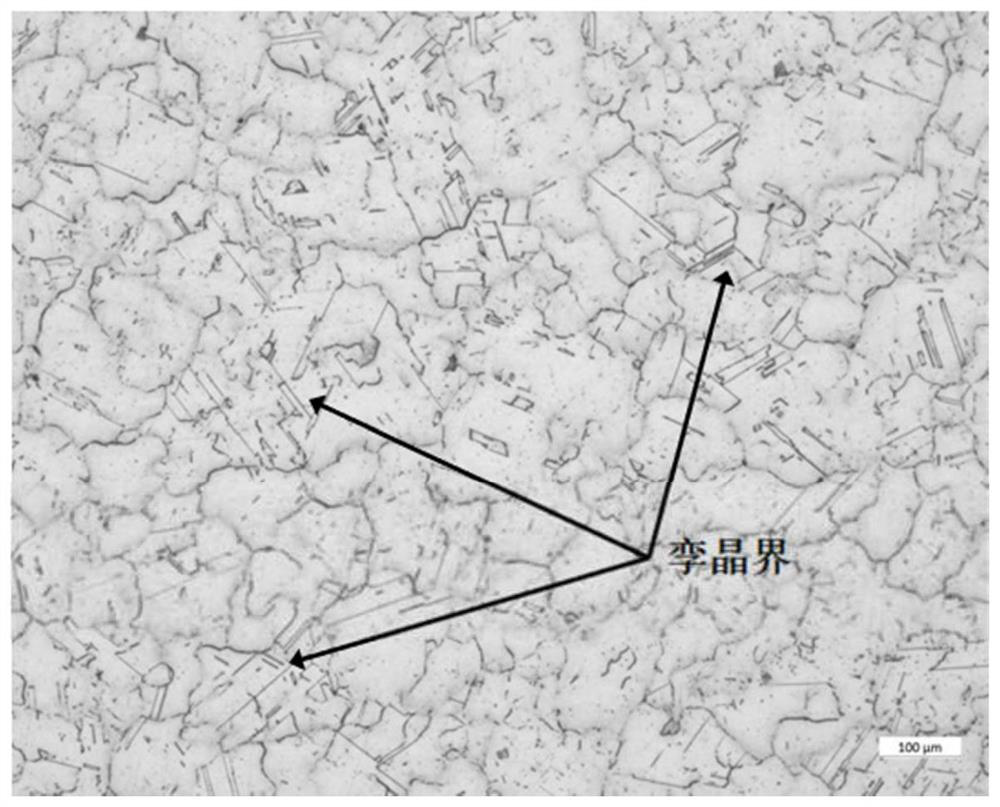

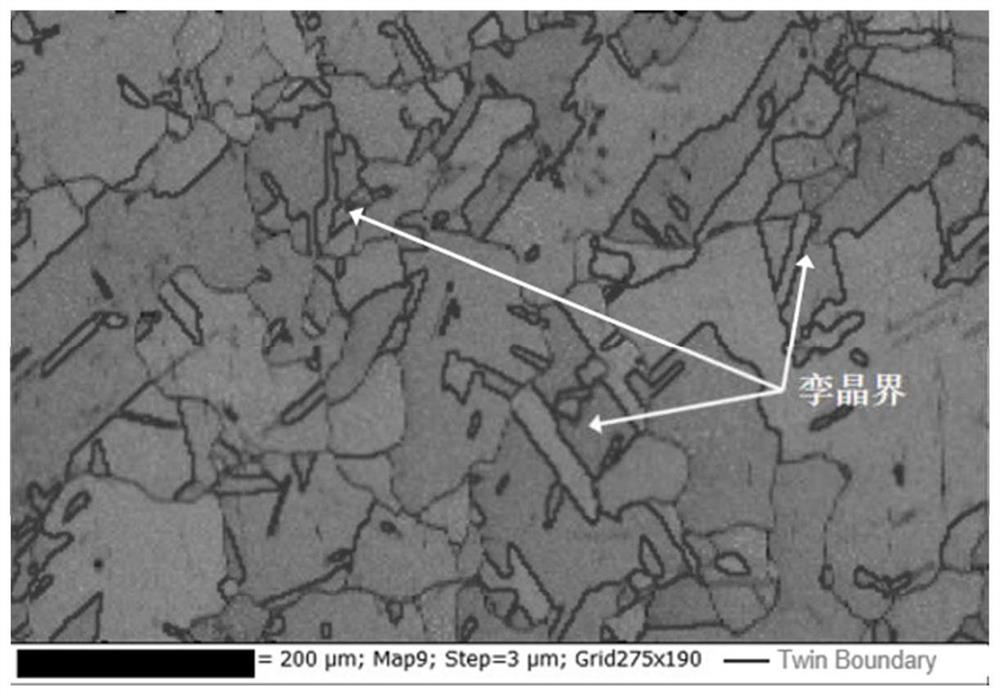

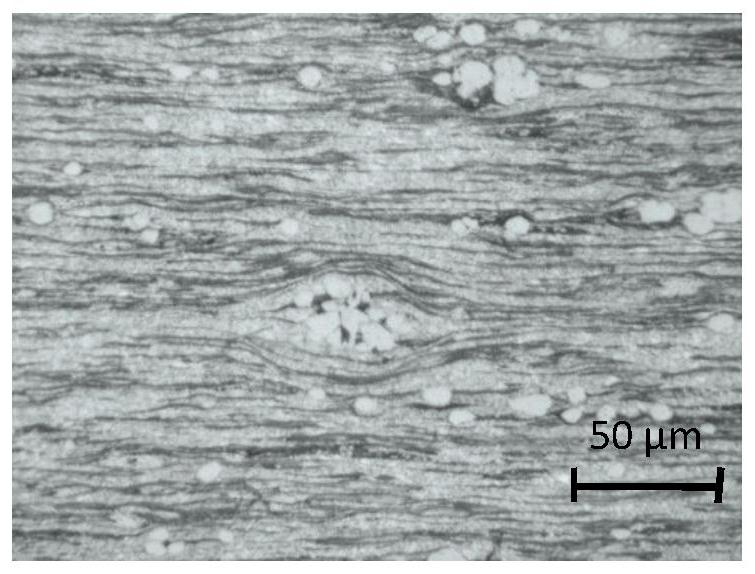

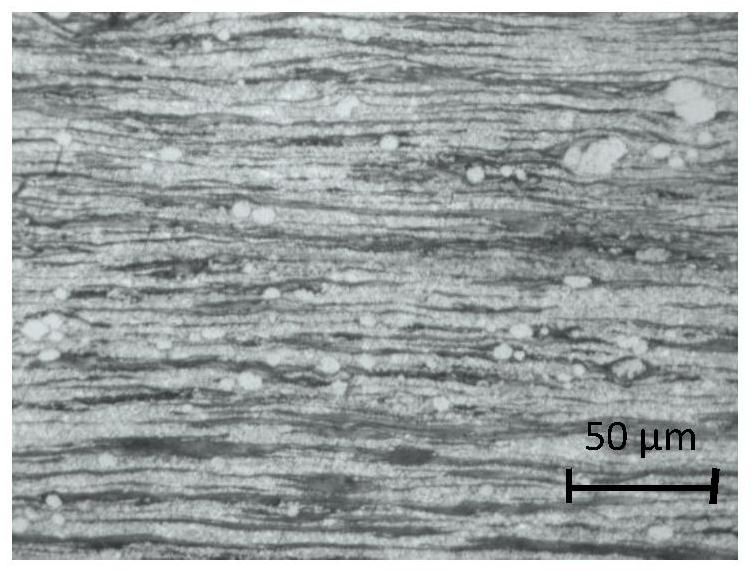

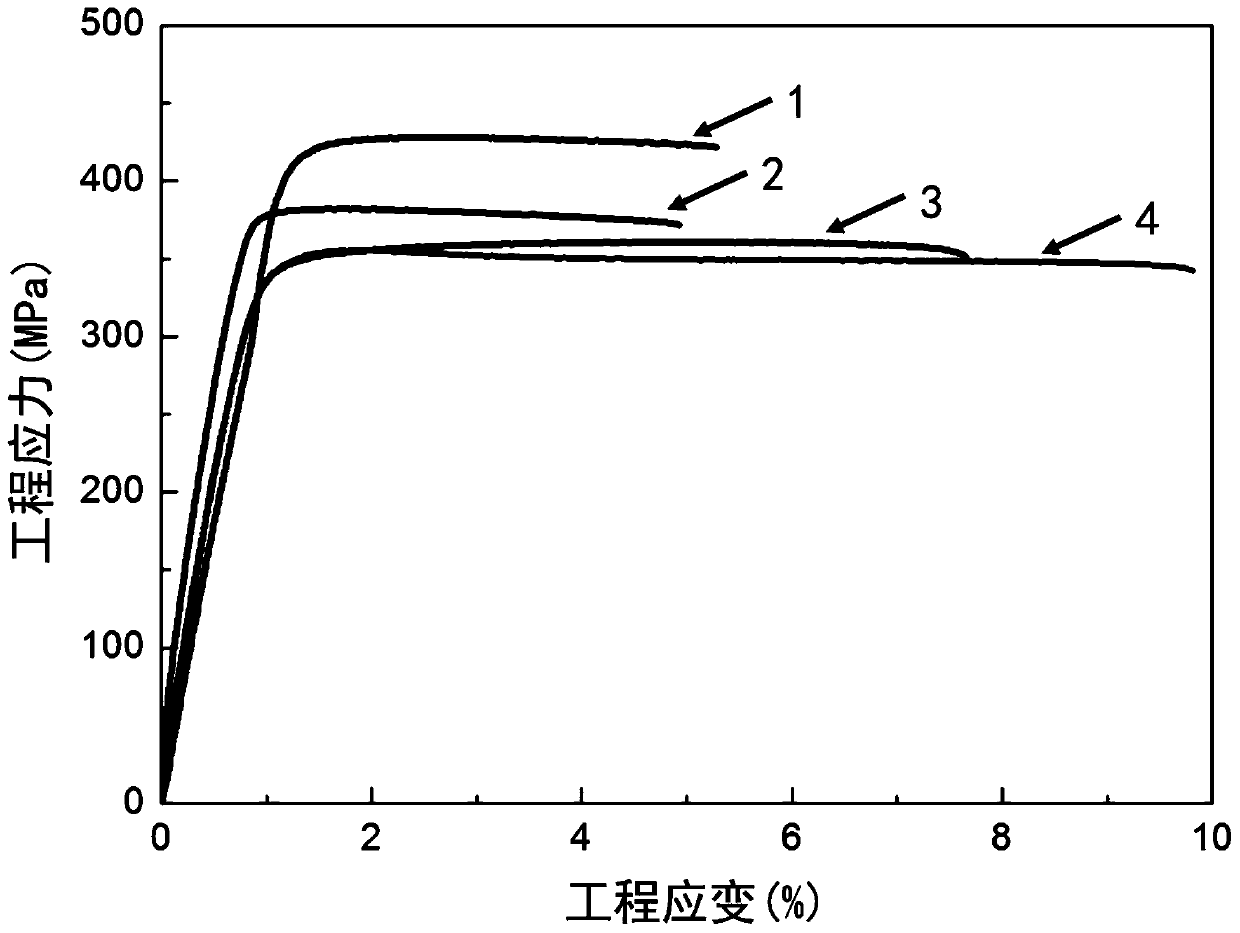

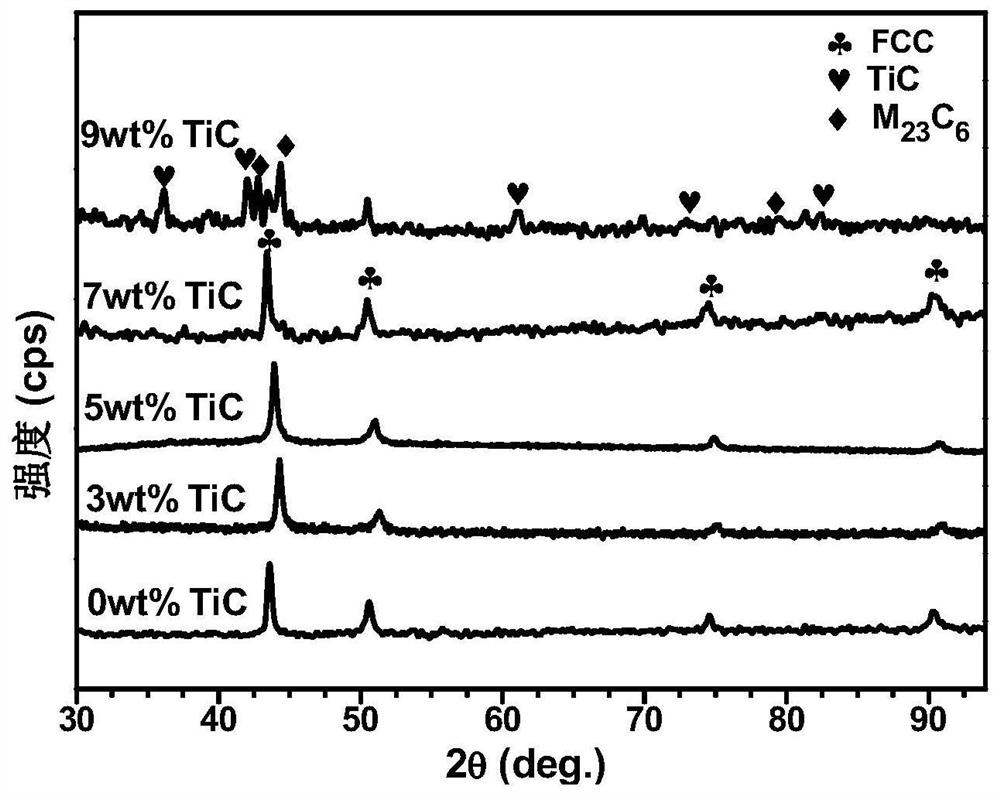

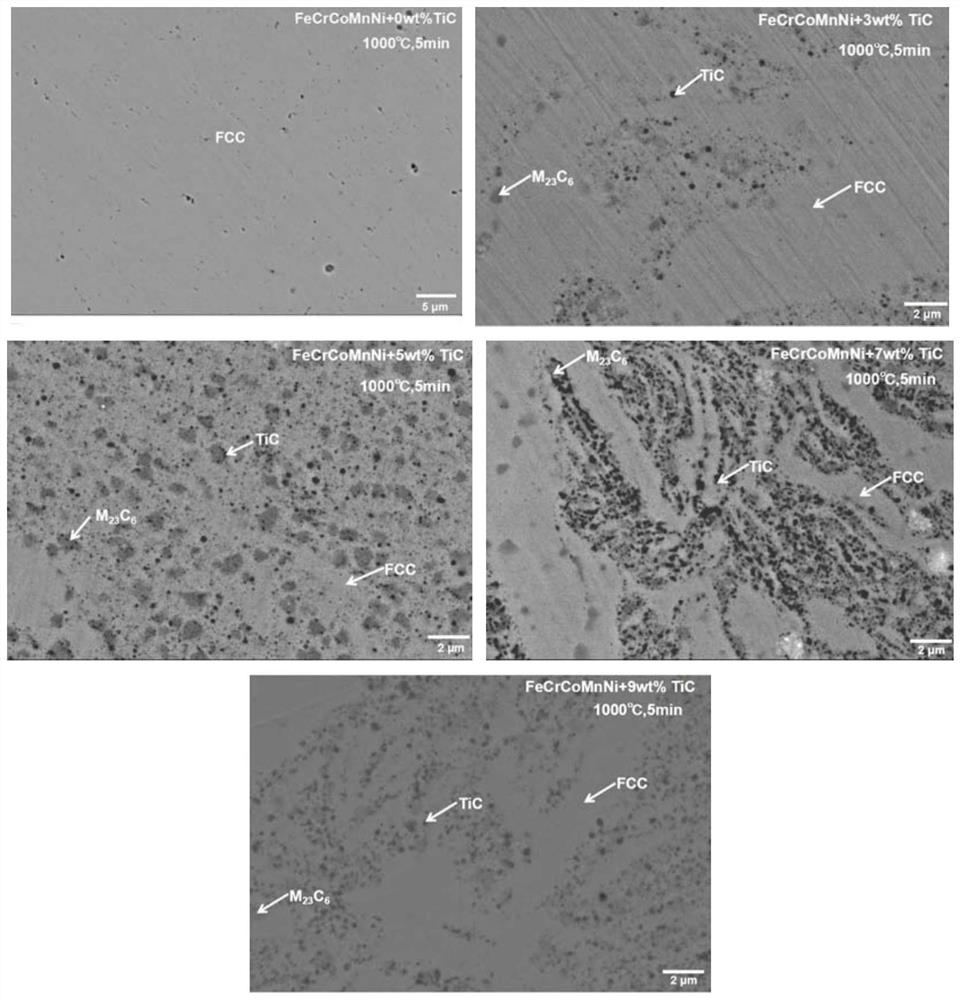

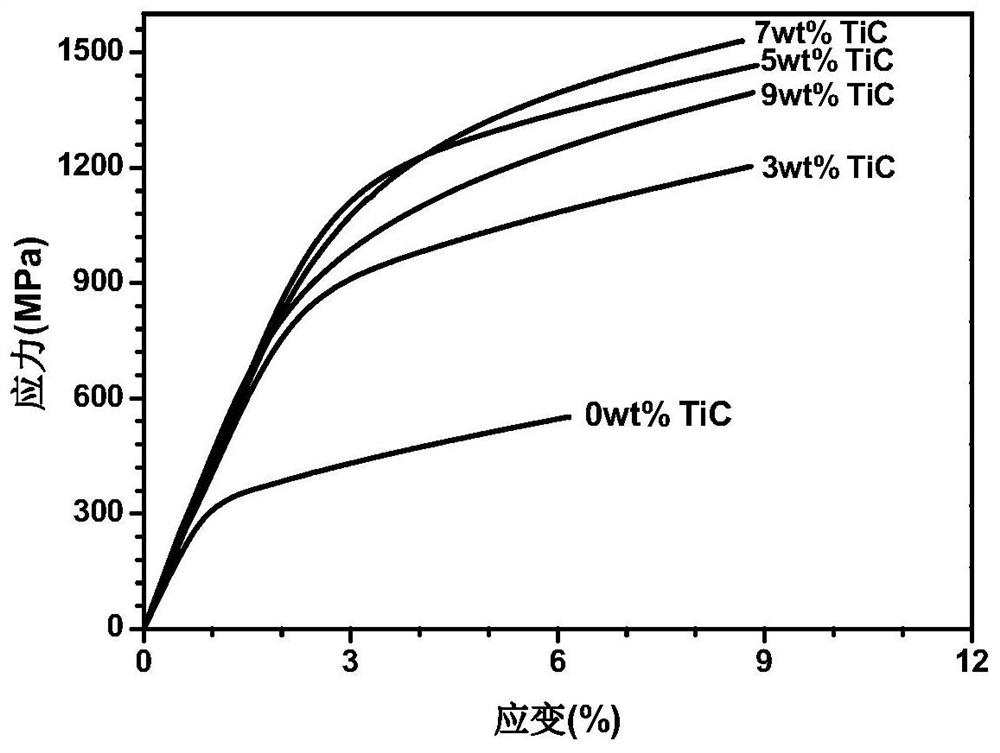

Preparation process of FeCrCoMnNi high-entropy alloy based composite material

ActiveCN110257684AImprove performanceSimple organizational structureHigh entropy alloysRoom temperature

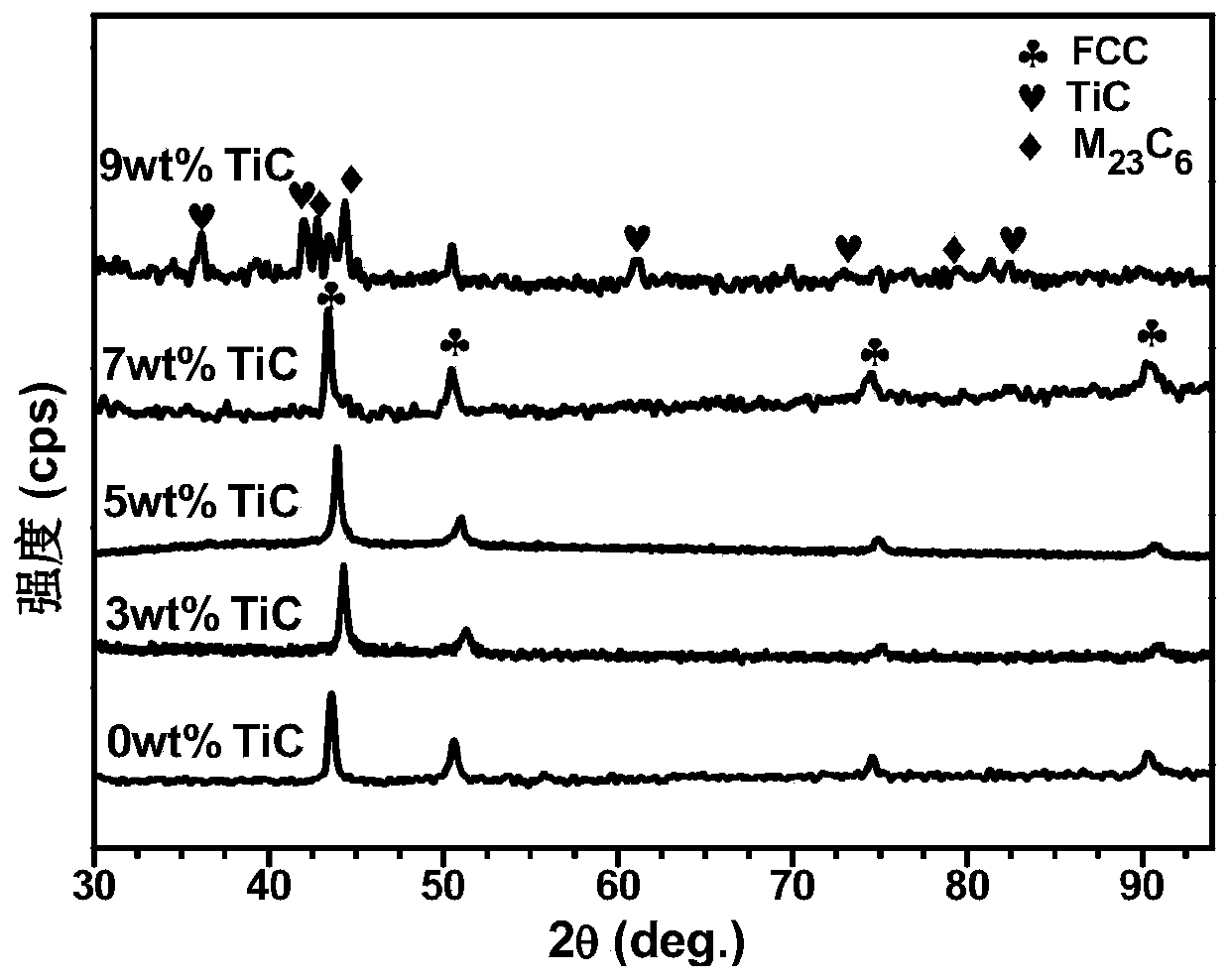

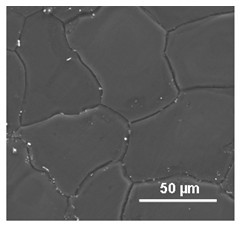

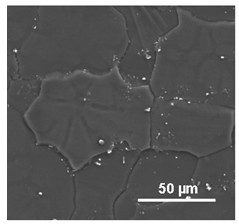

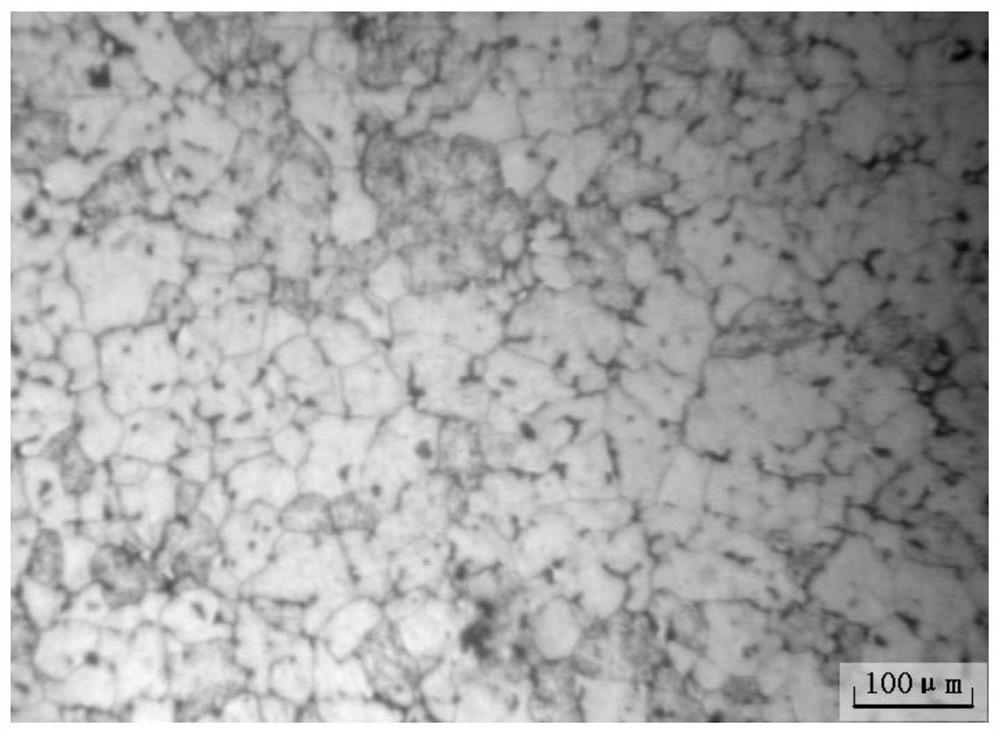

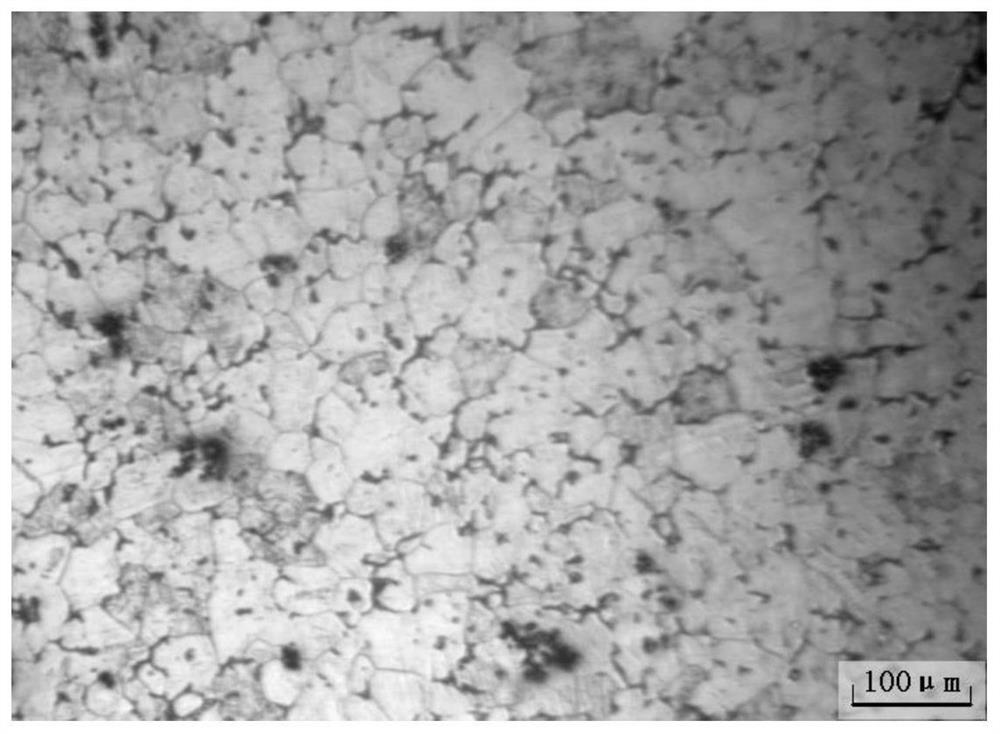

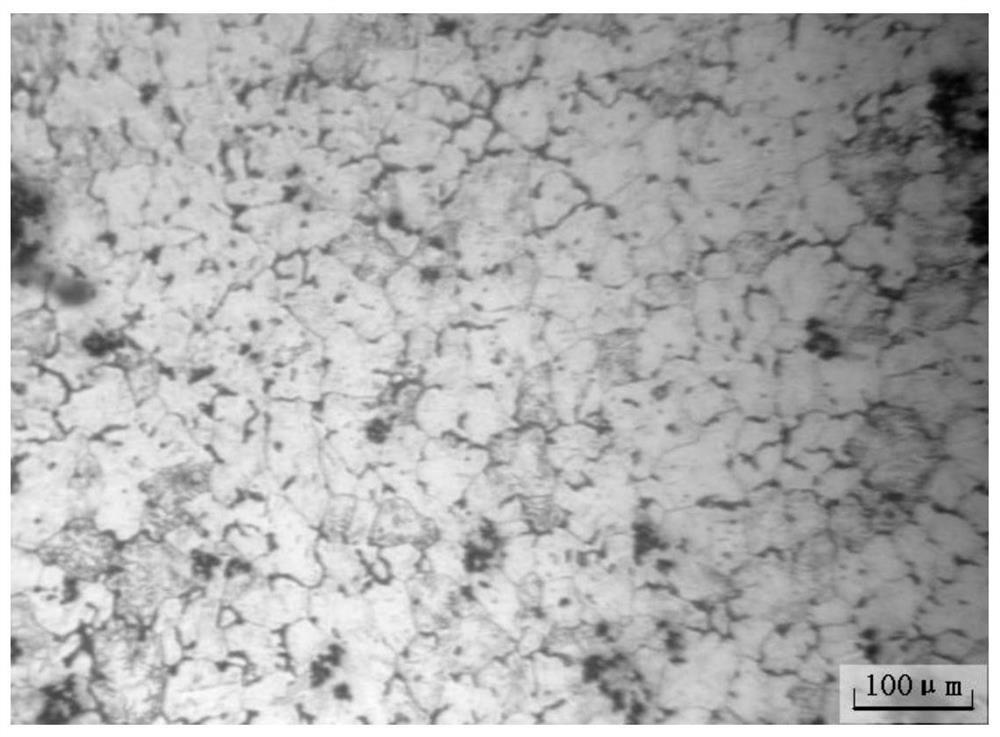

The invention discloses a preparation process of a FeCrCoMnNi high-entropy alloy based composite material. The composite material is prepared from FeCrCoMnNi powder and nano TiC powder through a discharge plasma sintering process and comprises the raw materials including, by mass, 91%-97% of the FeCrCoMnNi and 3%-9% of the TiC. According to the preparation process, the performance of the FeCrCoMnNi high-entropy alloy based composite material obtained through discharge plasma sintering is better when the sintering temperature is 1000 DEG C, the loading pressure is 50 MPa, the holding time is 5 min and the TiC addition amount is 7%; and the hardness is 1092.4HV, the room temperature yield strength is 979.7 MPa, and the 600 DEG C high temperature yield strength is 563.6 MPa. The TiC and an M23C6 strengthening phase formed by a reaction are uniformly distributed in a FeCrCoMnNi high-entropy alloy base, and the effect of dispersion strengthening is achieved.

Owner:HEFEI UNIV OF TECH

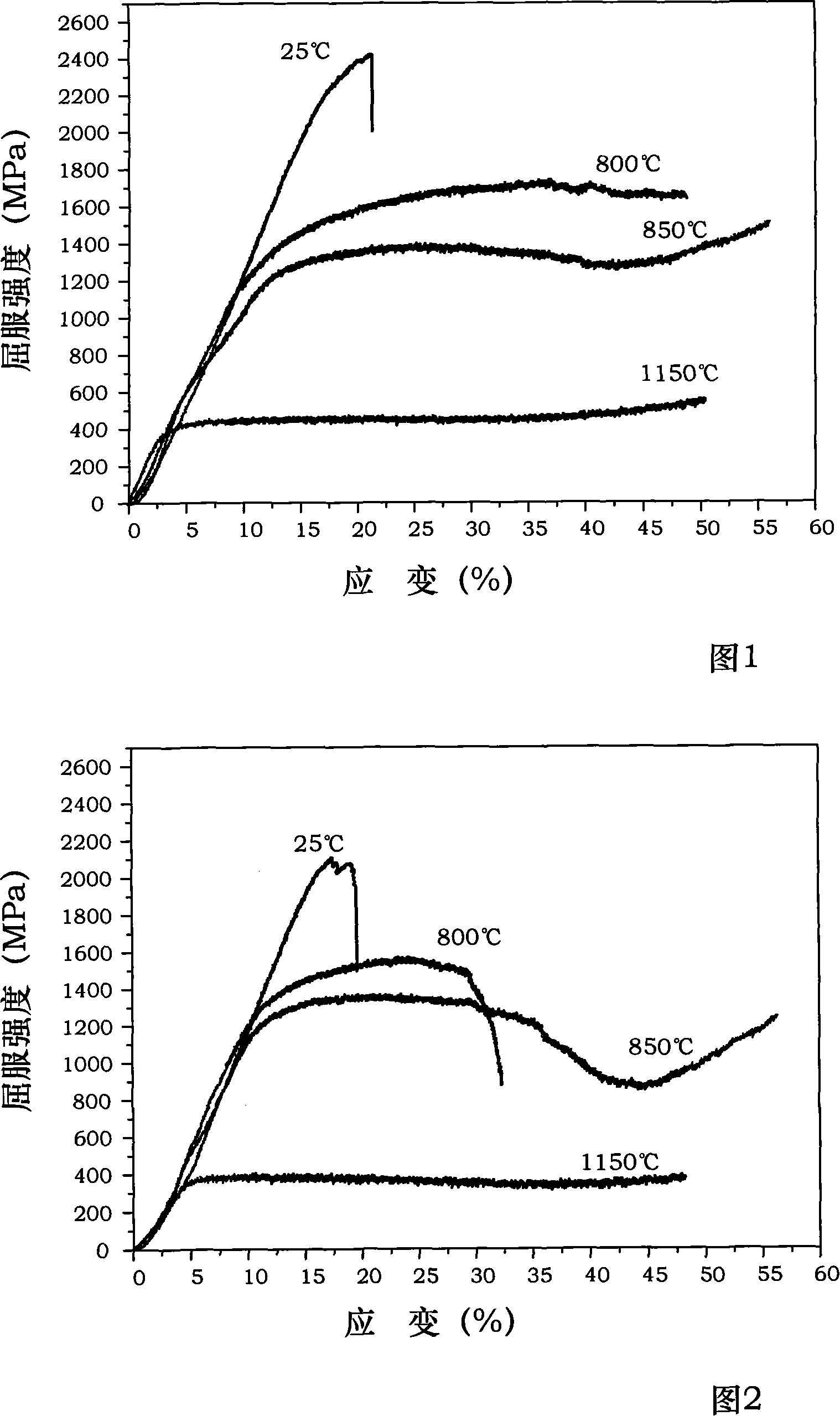

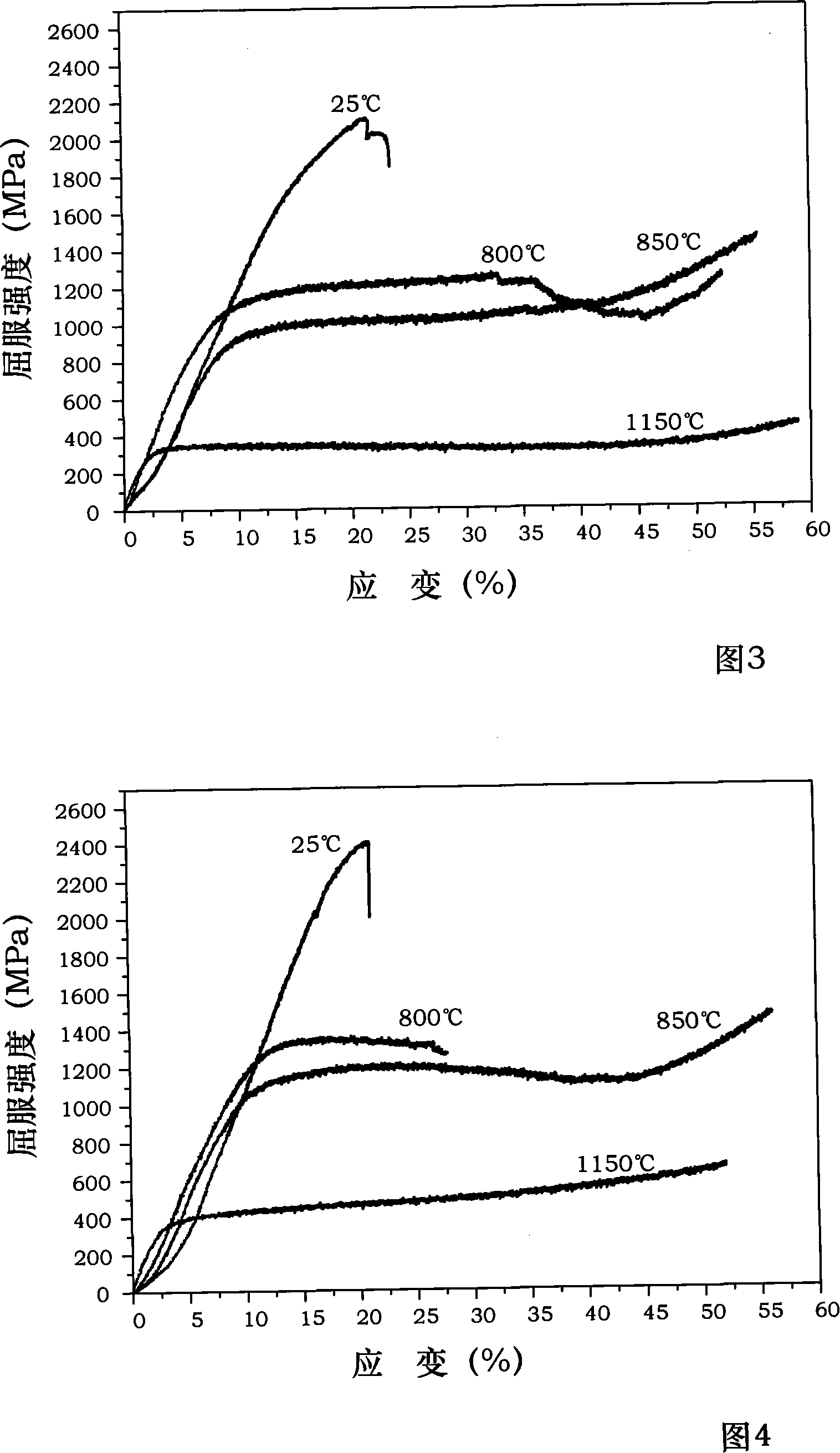

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Hf

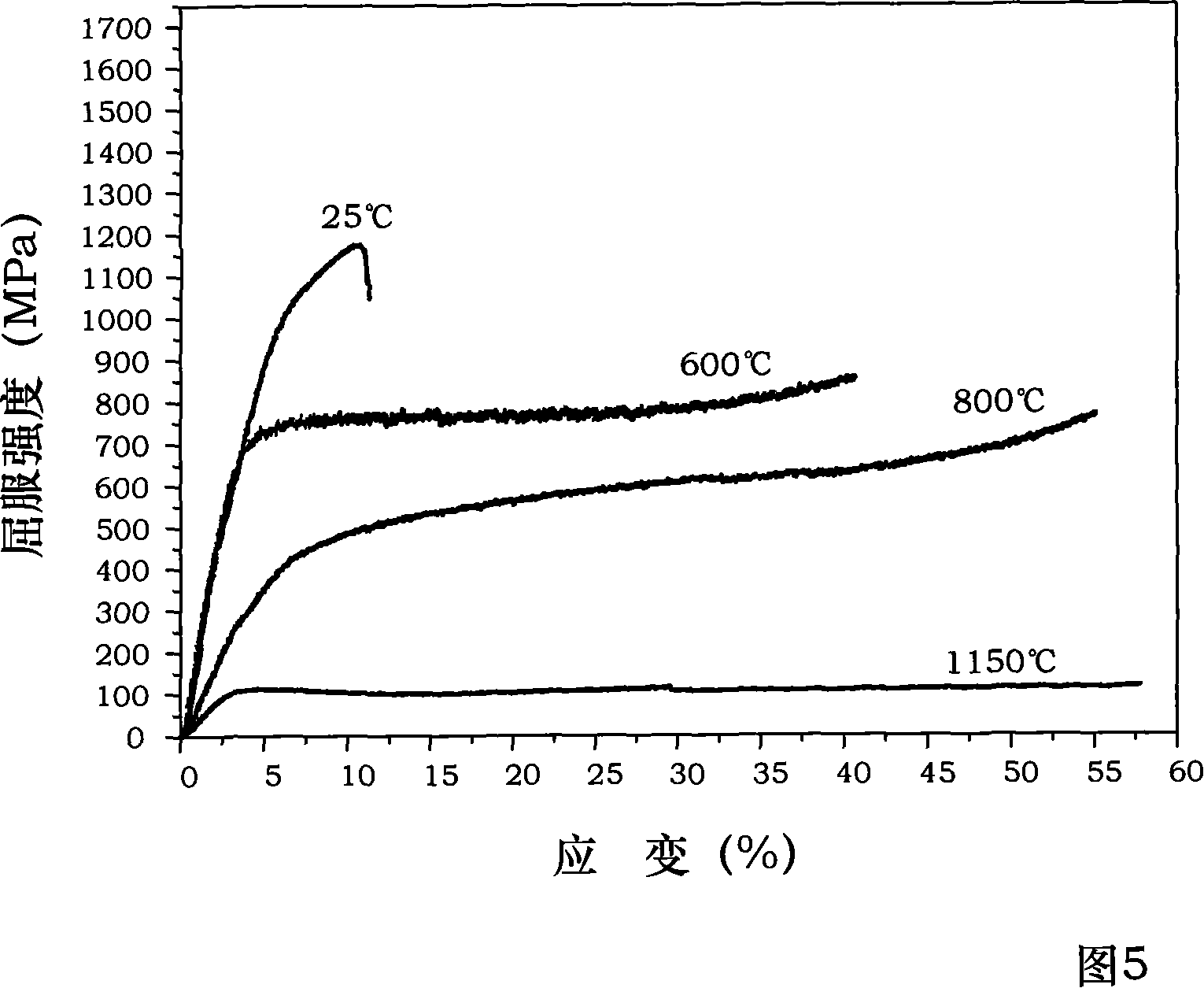

InactiveCN101148727AImprove high temperature strengthImprove performanceRoom temperatureUltimate tensile strength

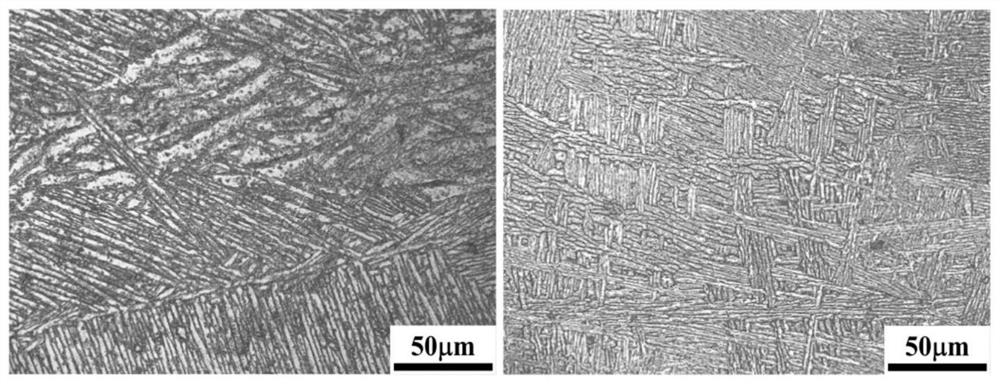

The present invention discloses one kind of Hf modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, Hf in 0.1-11 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding Hf element to modify and form one Heusler (L21-Ni2AlHf) phase with NiAl, the Hf modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has high room temperature toughness and plasticity and further raised high temperature strength. The Hf modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 300-420 MPa and density of 6.02-7.66 g / cu cm.

Owner:BEIHANG UNIV

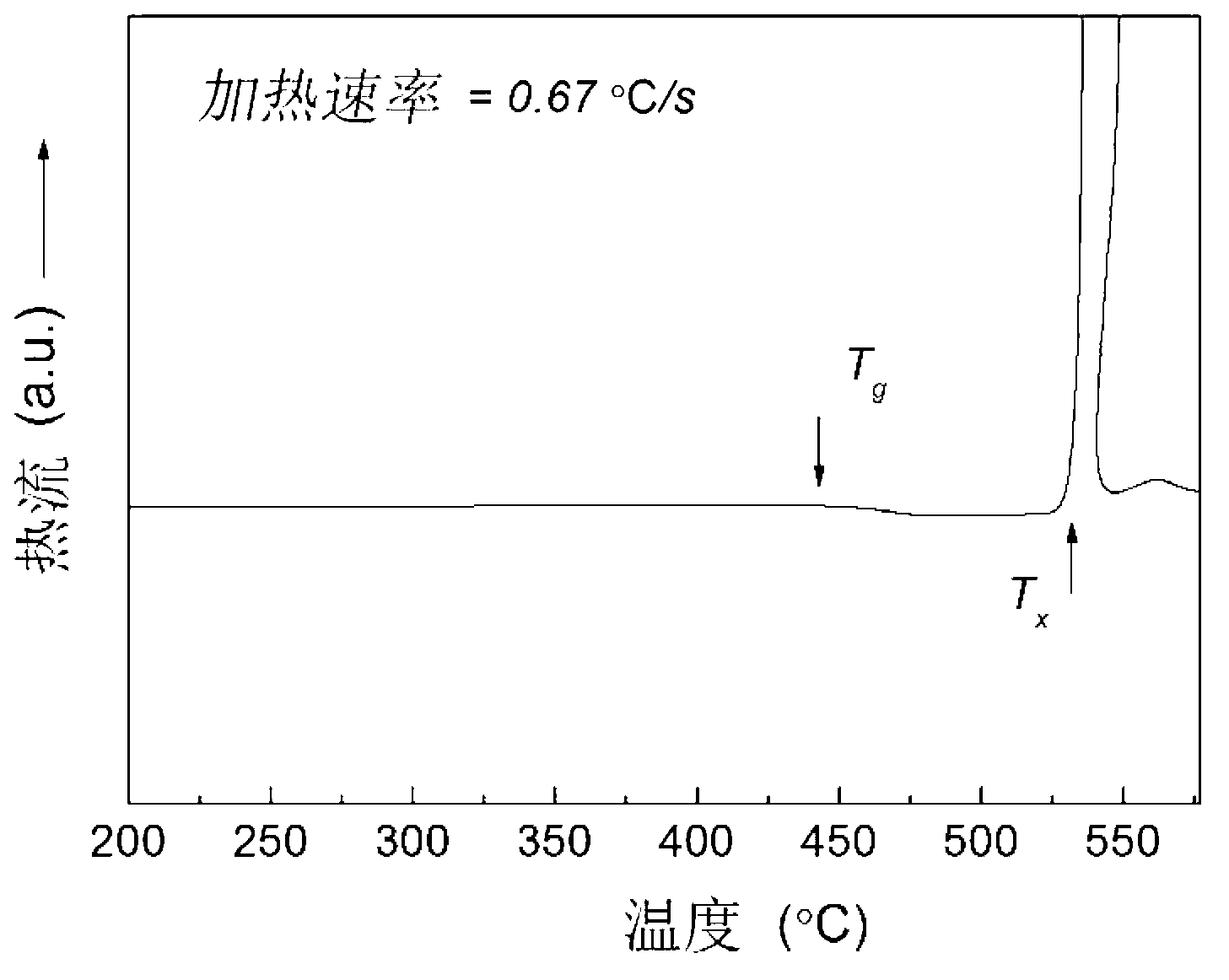

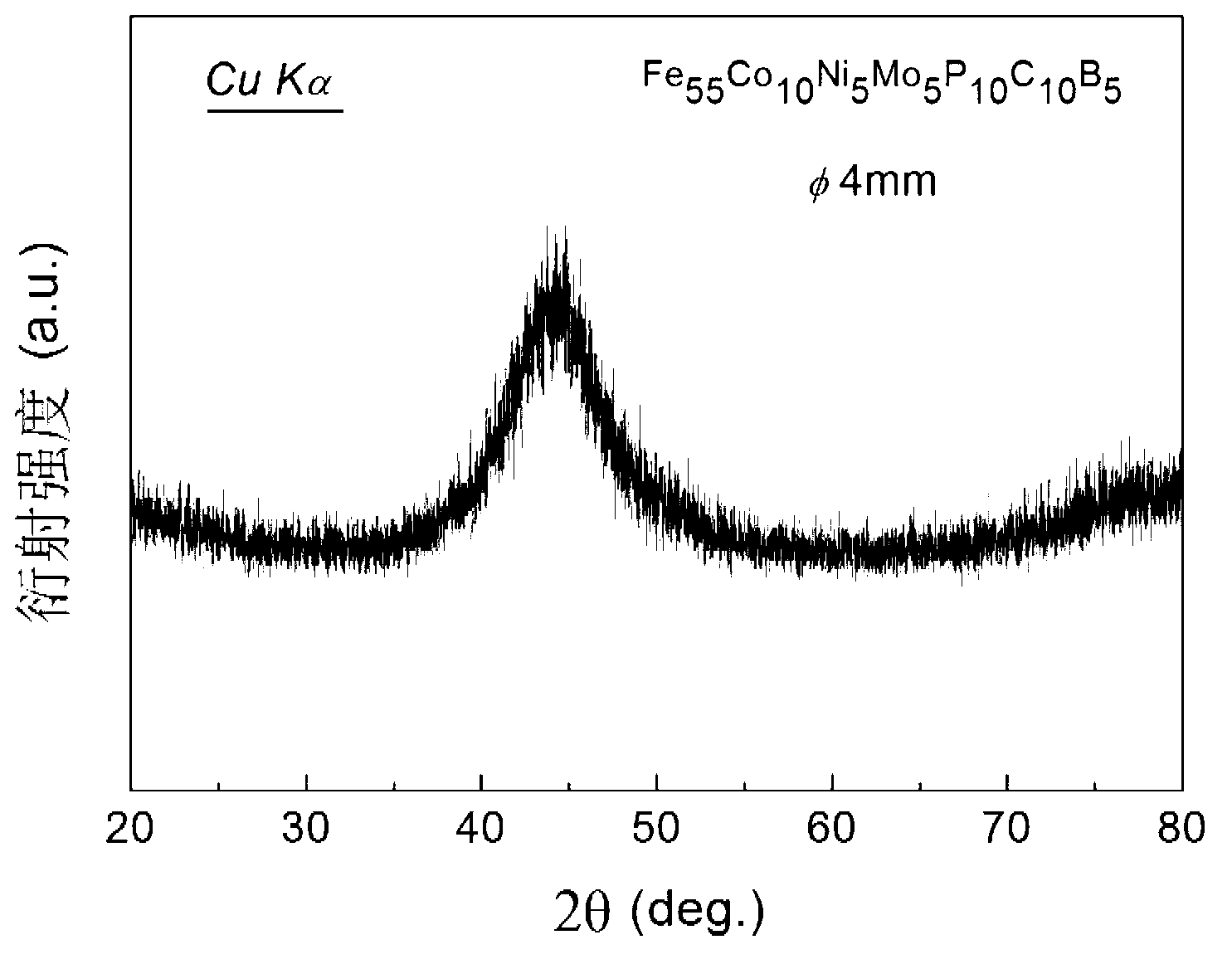

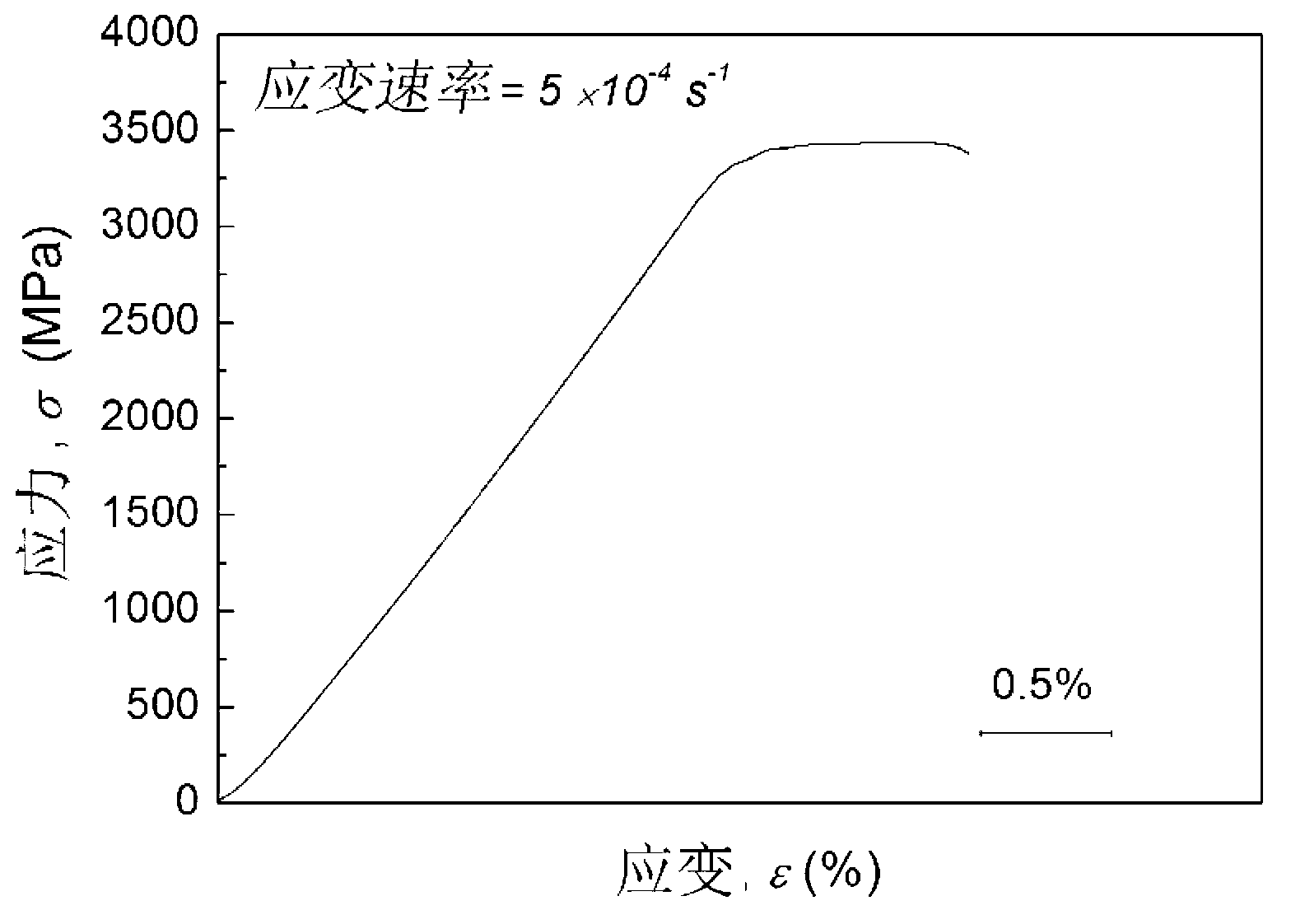

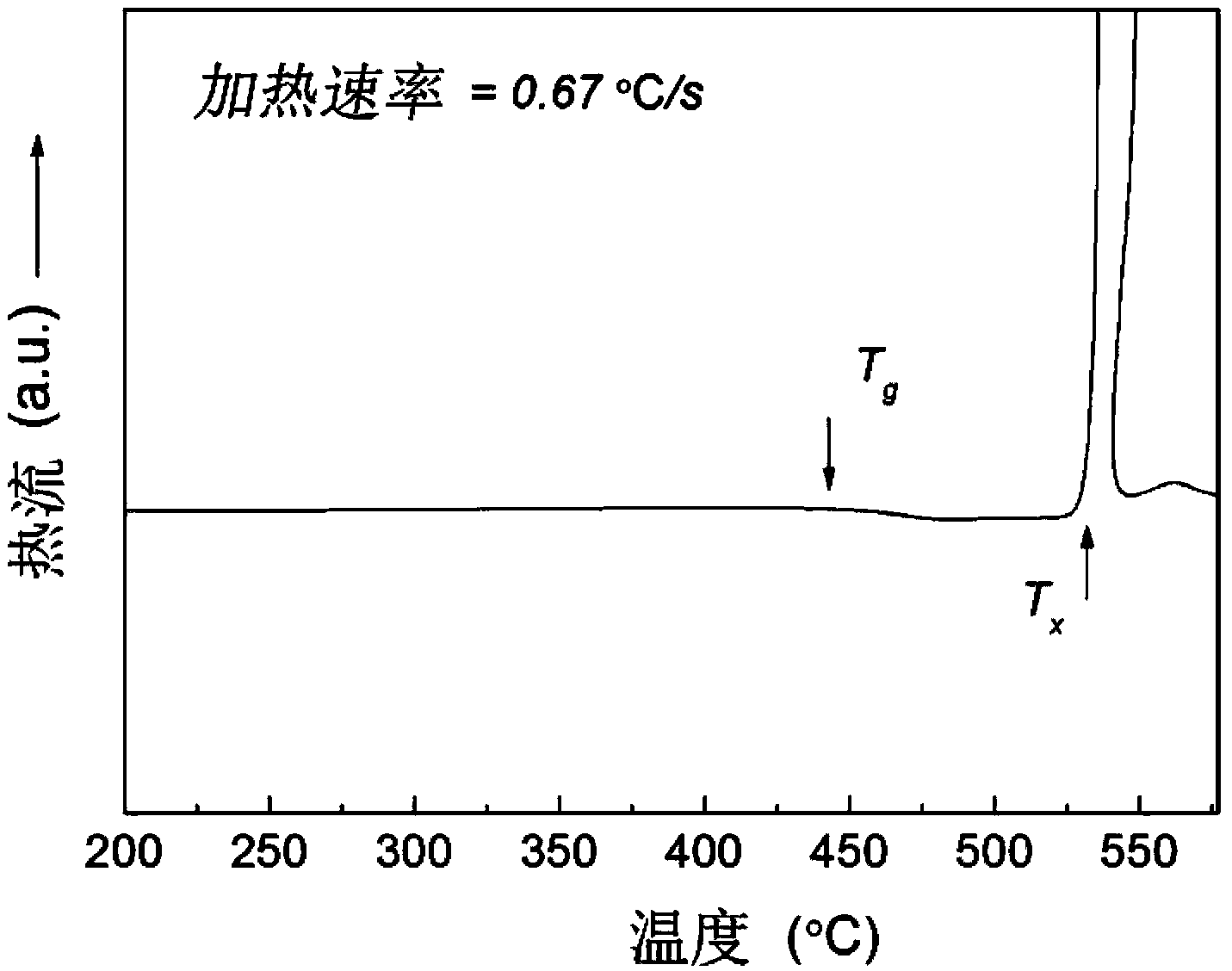

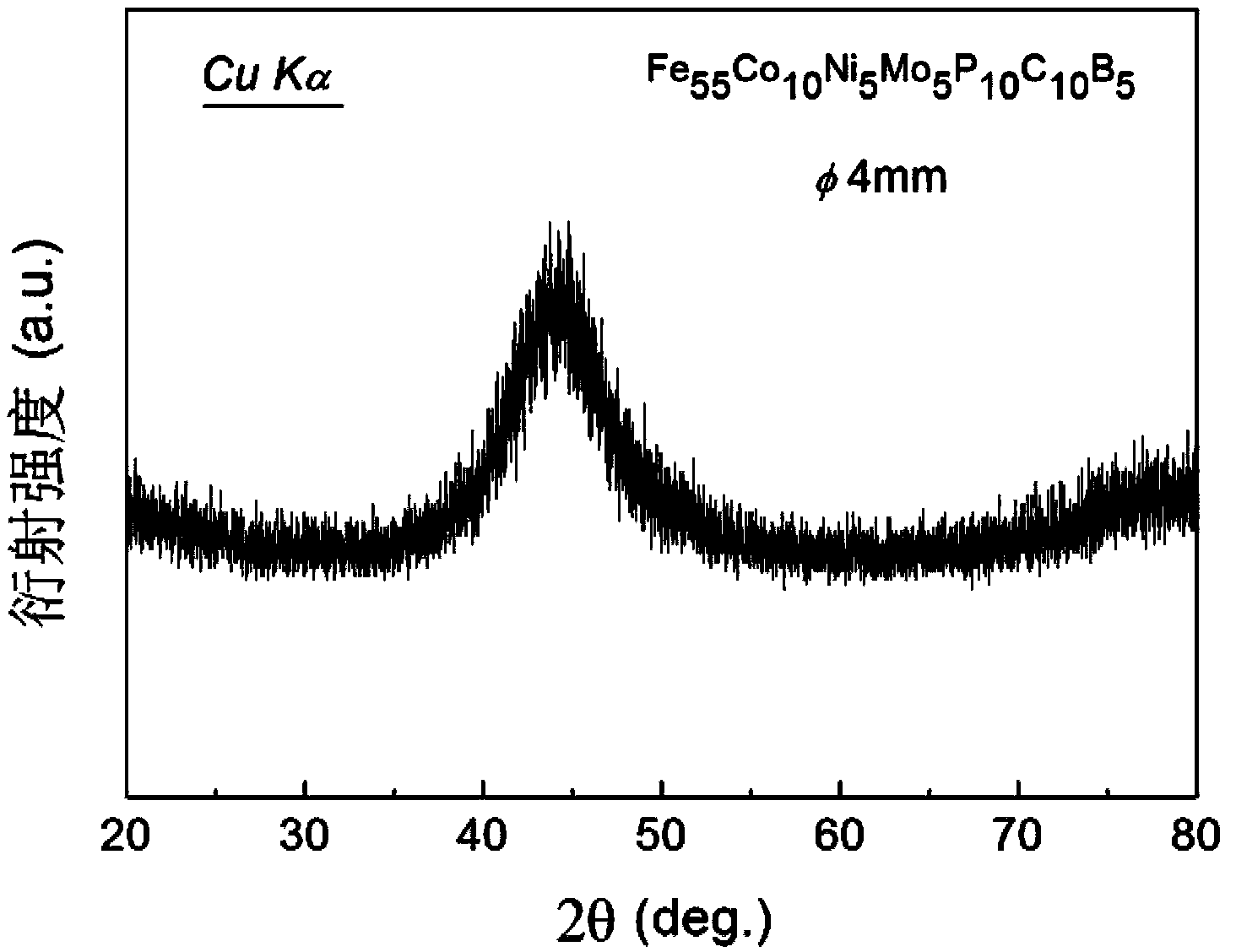

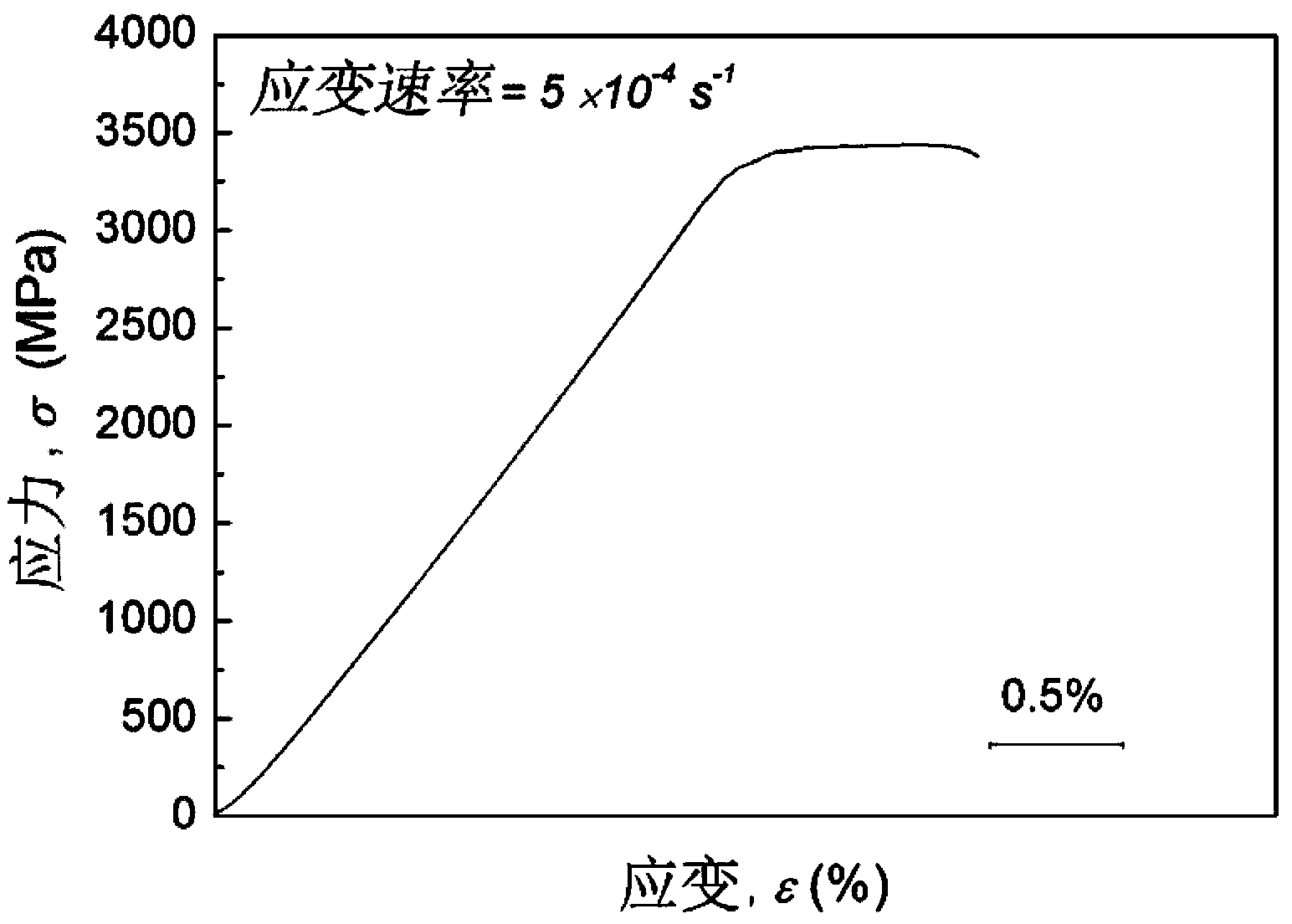

Iron-based bulk metallic glass alloy with large supercooled liquid phase region

The invention relates to an iron-based bulk metallic glass alloy with a large supercooled liquid phase region and belongs to the technical field of novel materials. The iron-based bulk metallic glass alloy with the large supercooled liquid phase region is characterized by consisting of iron, nickel, cobalt, molybdenum, chromium, tungsten, phosphorus, carbon, boron and silicon and having a composition expression of FexNiyCozMoaCrbWcPdCeBfSig, wherein x, y, z, a, b, c, d, e, f and g respectively represent atom percent content of each corresponding component; x is 50 to 70 percent; y is 0 to 20 percent; z is 0 to 15 percent; a is 2 to 6 percent; b is 0 to 4 percent; c is 0 to 3 percent; d is 8 to 15 percent; e is 10 to 12 percent; f is 2 to 6 percent; g is 0 to 2 percent; x+y+z is 50 to 75 percent; a+b+c is 4 to 10 percent; and x+y+z+a+b+c+d+e+f+g is equal to 100 percent. The alloy has the typical composition expression of Fe55Co10Ni5Mo5P10C10B5. The iron-based bulk metallic glass alloy has the effects and the benefits that the alloy simultaneously has the advantages of low glass transition temperature, large supercooled liquid phase interval, high glass-forming ability, low coercive force, excellent mechanical performance, low viscosity coefficient in a cold liquid phase interval and the like, can implement micron-grade and nano-grade superplasticity processing, and is a novel iron-based soft magnetic metallic glass alloy for superplasticity processing, with low production cost.

Owner:DALIAN UNIV OF TECH

High-aluminum stainless steel based on 310S

The invention discloses high-aluminum stainless steel based on 310S, which comprises the following compositions by mass percentage: 19.00 to 22.00 percent of nickel, 24.00 to 26.00 percent of chromium, less than or equal to 1.5 percent of silicon, less than or equal to 0.035 percent of phosphorus, less than or equal to 0.03 percent of sulfur, less than or equal to 0.08 percent of carbon, less than or equal to 2.0 percent of manganese, 2 to 10 percent of aluminum and the balance of iron.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Heat treatment process for improving strength and plasticity of magnesium alloy

The invention provides a heat treatment process for simultaneously improving the strength and the plasticity of a magnesium alloy, comprising the following steps of: carrying out solid solution on a magnesium alloy casting ingot prepared by utilizing a semicontinuous casting process at 360-4,000 DEG C, preserving the temperature for 8-12h, carrying out water quenching and cooling to room temperature, then heating the magnesium alloy treated by the technical scheme to 150-2,000 DEG C, ageing, preserving the temperature for 15-30h, and air-cooling to the room temperature. The heat treatment process of the invention can remarkably improve the room temperature yield strength, the tensile strength and the plasticity of the magnesium alloy material and can solve the contradiction of the strength and the plasticity of the magnesium alloy. The magnesium alloy treated by the heat treatment process can provide an important basis for the subsequent high-strength and high-plasticity deformed magnesium alloy and benefits to the full development of the use performance potential of the material. In addition, the invention has the advantages of simple equipment and lower cost and is easy to operate.

Owner:CHONGQING SUN MAGNESIUM COMPANY

High-toughness heat-resistant Mg-Gd alloy suitable for gravity casting and preparation method thereof

The invention provides a high-toughness heat-resistant Mg-Gd alloy suitable for gravity casting and a preparation method thereof. The alloy comprises the following chemical components of, in percentage, 4.0-10.0% of Gd, 2.0-6.0% of Zn, 0.5-1.2% of Al, 0.1-0.3% of Mn, 0.01-0.08% of M, and the balance Mg, wherein the M is one or two elements of Ti and B; the preparation method comprises the following steps that (1) burdening is performed according to a Mg-Gd alloy component; (2) an industrial pure magnesium ingot is melted; (3) heating is performed to 700 DEG C, and industrial pure zinc, an Mg-Gd and Mg-Mn intermediate alloy are melted; (4) heating is performed to 730 DEG C, after an industrial pure aluminum ingot, Al-Ti, Al-Ti-B and Al-B intermediate alloys added are all melted, refining isperformed to obtain a magnesium alloy melt; (5) gravity casting is performed; and (6) secondary solid solution and artificial aging treatment are performed. According to the high-toughness heat-resistant Mg-Gd alloy and the preparation method, after the alloy is subjected to the gravity casting, the secondary solid solution treatment and the artificial aging heat treatment, the tensile strength at room temperature is 300 MPa, the elongation percentage is 15%, the high-temperature tensile strength at 200 DEG C is 218 MPa, the elongation percentage is 20%, and the high-end requirement for lightweight development in the industries of aerospace, automobiles, telecommunication and the like is met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A <111> textured nano-twinned Cu bulk material and its preparation method

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Rare-earth-free low-alloy high-toughness aluminum alloy and preparation method thereof

The invention discloses a rare-earth-free low-alloy high-toughness aluminum alloy and a preparation method thereof, and relates to the field of metal materials and metal material processing, in particular to an aluminum alloy and a preparation method thereof. The invention aims to solve the problem of low yield strength of the existing aluminum alloy, and provides the rare-earth-free low-alloy high-toughness aluminum alloy and the preparation method of the rare-earth-free low-alloy high-toughness aluminum alloy. The rare-earth-free low-alloy high-toughness aluminum alloy is composed of Al and alloy elements, the mass fraction of the alloy elements is smaller than or equal to 10%, and the balance is Al. The alloy elements are composed of Cu, Mg, Ag, Mn, Zr, Sb, Be and Cr. The preparation method comprises the following steps: 1, smelting and casting to obtain cast alloy; 2, homogenization treatment; 3, machining; 4, extruding and deforming; and 5, carrying out aging heat treatment to obtain the rare-earth-free low-alloy high-toughness aluminum alloy. The steel has the advantages that the yield strength at room temperature reaches 486-540 MPa, the tensile strength reaches 584-630 MPa, and the ductility is 9.0% or above. The method is mainly used for preparing the rare earth-free low-alloy high-toughness aluminum alloy.

Owner:SHANDONG NANSHAN ALUMINUM

High-Cr-content cast heading machine cutter steel and manufacturing technique thereof

ActiveCN107881435AImprove thermal fatigue crack levelImprove oxidation and corrosion resistanceFurnace typesHeat treatment furnacesThermal fatigueNear net shape

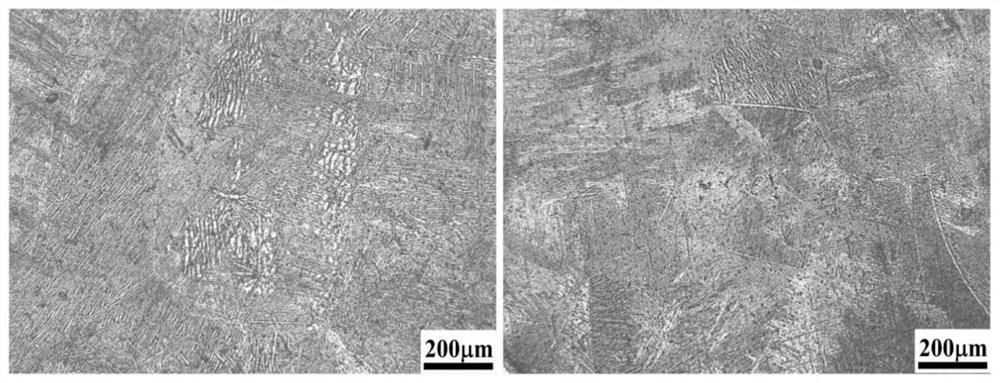

The invention relates to high-Cr-content cast heading machine cutter steel. The cutter steel comprises the chemical components of, by weight, 0.30%-0.55% of C, 8.0%-12.0% of Cr, 1.2%-3.0% of Mo, 0.5%-1.8% of Ni, 0.6%-1.0% of V, 0.1%-0.4% of Mn, 0.6%-0.8% of Si, 0.04%-0.30% of N, no more than 0.005% of S, no more than 0.03% of P and the balance Fe. The cutter steel manufacturing technique comprisesthe following steps that a near-net shape blank of a cutter is obtained through precise casting, then heat treatment is conducted, and a finished product is obtained directly after fine machining. Yield strength and tensile strength are improved while the hardness, impact toughness and elongation of the cutter steel all can reach the level of domestic forged heading machine cutter steel; the oxidation corrosion resistant capability, thermal fatigue resistant performance and abrasive grain abrasion resistance are improved; and the production period is shortened, and the production cost is reduced.

Owner:JILIN UNIV

High-strength and high-plasticity aluminum alloy and preparation method thereof

The invention relates to the technical field of metal materials and machining of the metal materials, and discloses high-strength and high-plasticity aluminum alloy and a preparation method of the high-strength and high-plasticity aluminum alloy. The aluminum alloy comprises the following components in percentage by mass: 5%-6% of Cu, 0.2%-1.0% of Mg, 0.2%-0.5% of Ag, 0.2%-0.4% of Mn, wherein themass fraction of alloy elements is smaller than or equal to 10%, and the balance is Al. By reasonably controlling the contents of Cu, Mg, Ag and Mn in the aluminum alloy, the aluminum alloy has high strength and high plasticity. The preparation method comprises the following steps: 1, carrying out smelting and casting to obtain an aluminum alloy ingot; 2, carrying out homogenization treatment; and3, carrying out extruding deforming to obtain the high-strength and high-plasticity aluminum alloy. The mechanical properties such as deformation strength and plasticity and toughness of the aluminumalloy are superior to those of traditional commercial wrought aluminum alloy 2D70, the as-cast comprehensive mechanical properties of the aluminum alloy are superior to those of traditional commercial cast aluminum alloy 2024, and the aluminum alloy is suitable for aerospace materials.

Owner:YANTAI NANSHAN UNIV

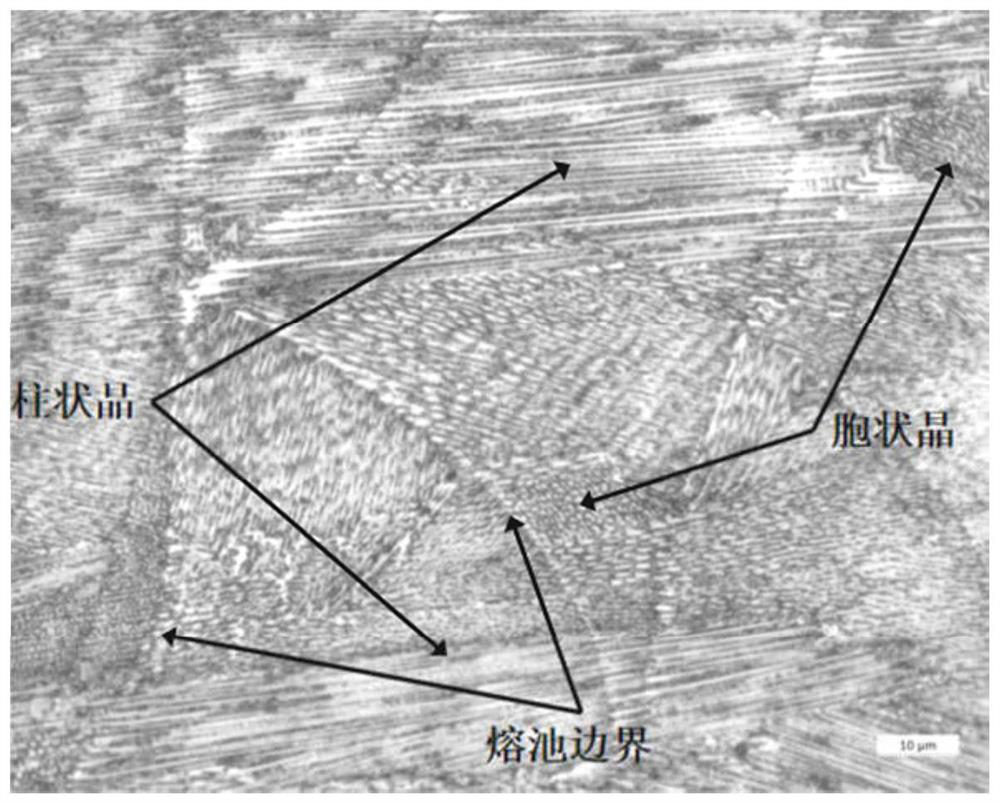

Preparation method of high-strength and high-plasticity Inconel718 alloy based on SLM

ActiveCN113477942AIncrease profitLow costAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSolution treatment

A preparation method of a high-strength and high-plasticity Inconel 718 alloy based on SLM comprises the following steps: S1, selective laser melting forming is conducted, specifically, an Inconel 718 alloy blank is printed through a selective laser melting method; and the Inconel 718 alloy blank is sequentially subjected to step S2: isostatic pressing heat treatment, step S3: stress relief annealing treatment, step S4: solution treatment and step S5: two-stage aging treatment, specifically, the temperature of isostatic pressing heat treatment is 1165-1170 DEG C, the pressure intensity is 125-135 Mpa, and the time is 210-270 min; the temperature of stress relief annealing is 790-810 DEG C, and the time of stress relief annealing is 20-40 min; the temperature of solution treatment is 940-960 DEG C, and the time of solution treatment is 20-40 min; and in two-stage aging treatment, the temperature of first-stage aging treatment is 750-770 DEG C, the time of first-stage aging treatment is 470-490 min, the temperature of second-stage aging treatment is 640-660 DEG C, and the time of second-stage aging treatment is 470-490 min. The Inconel 718 alloy prepared by the method has strength, plasticity and hardness and has excellent comprehensive mechanical properties, and the application of the Inconel 718 alloy can be expanded to the field of more precise and complex structures.

Owner:SOUTHWEST JIAOTONG UNIV

High-strength high-toughness heat-resistant Mg-Er alloy suitable for gravity casting and preparation method thereof

The invention provides a high-strength high-toughness heat-resistant Mg-Er alloy suitable for gravity casting and a preparation method thereof. The alloy is prepared from the following chemical components in percentage by mass: 4.0-10.0% of Er, 2.0-6.0% of Zn, 0.5-1.2% of Al, 0.1-0.3% of Mn, 0.01-0.08% of M, and the balance Mg, specifically, M is one or two elements of Ti and B. The preparation method comprises the following steps: (1) carrying out burdening according to the Mg-Er alloy components; (2) melting an industrial pure magnesium ingot; (3) rising the temperature to 700 DEG C to meltindustrial pure zinc, the Mg-Er intermediate alloy and a Mg-Mn intermediate alloy; (4) rising the temperature to 730 DEG C, and adding and melting an industrial pure aluminum ingot, an Al-Ti intermediate alloy, an Al-Ti-B intermediate alloy, and an Al-B intermediate alloy to obtain a magnesium alloy melt; (5) carrying out gravity casting; and (6) carrying out secondary solid solution and artificial aging treatment. After gravity casting, secondary solid solution treatment and artificial aging heat treatment, the alloy provided by the invention has tensile strength of 296 MPa and elongation rate of 18% at room temperature; while at high temperature of 200 DEG C, the tensile strength is 215 MPa and the elongation is 23%; and the requirements of aerospace, automobile, telecommunication and other industries for light weight are met.

Owner:FENGYANG L S NET FORMING CO LTD +1

High-strength-toughness and heat-resistance Mg-Gd alloy suitable for low-pressure casting and preparation method thereof

ActiveCN109881066AImprove mechanical propertiesImprove high temperature performanceChemical compositionHeat resistance

The invention discloses a high-strength-toughness and heat-resistance Mg-Gd alloy suitable for low-pressure casting and a preparation method thereof. The chemical composition of the alloy comprises the following in mass percentage: 4.0-8.0% of Gd, 1.2-4.8% of Zn, 0.5-1.2% of Al, 0.1-0.3% of Mn, 0.01-0.08% of M and the balance Mg and other unavoidable impurities, wherein, M is at least one elementof Ti and B. After the low-pressure casting, secondary solid-soluble treatment and artificial aging heat treatment are conducted on the high-strength-toughness and heat-resistance Mg-Gd alloy suitablefor low-pressure casting, the room temperature tensile strength is more than 280 MPa, the extension rate is more than 16%, the high-temperature stretching tensile strength at 200 DEG C is more than 190 MPa, the elongation rate is more than 16%, and the high-end demand of the lightweight development in the industries such as aerospace, military and automobiles is met.

Owner:SHANGHAI JIAO TONG UNIV

Nano twin crystal copper material with ultrahigh strength and superhigh conductivity as well as preparation method

InactiveCN1234914CImprove propertiesUnique microstructurePhotography auxillary processesProcess efficiency improvementElectrical resistance and conductanceElectrolysis

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

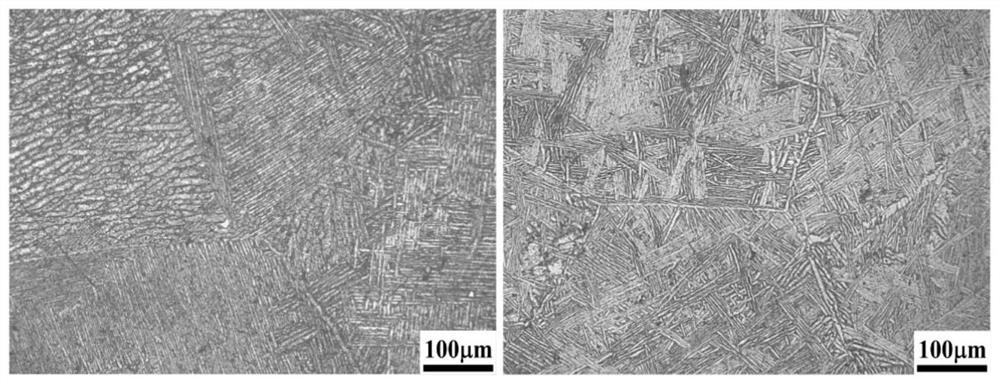

Nanoparticle reinforced ZTC4 titanium alloy and preparation method thereof

The invention is applicable to the technical field of titanium alloys, and provides a nanoparticle reinforced ZTC4 titanium alloy and a preparation method thereof. The reinforcing nano particles are nano TiC particles and can be used for improving the strength of the ZTC4 titanium alloy. Specifically, the ZTC4 titanium alloy comprises the following components in percentage by mass: 5.5%-6.8% of Al, 3.5%-4.5% of V, 88.4%-90.99% of Ti, 0.01%-0.3% of nano TiC particles and the balance of impurity elements, wherein the sum of the mass percentages of the components is 100%. The nano TiC particles are added into the ZTC4 titanium alloy, so that the strength of the ZTC4 titanium alloy is remarkably improved unexpectedly, it can be guaranteed that the elongation of the ZTC4 titanium alloy is not greatly changed, and great significance in application of the ZTC4 titanium alloy in a high-strength environment is achieved.

Owner:JILIN UNIV

Rare earth-free low-alloy super-high-toughness magnesium alloy and preparation method thereof

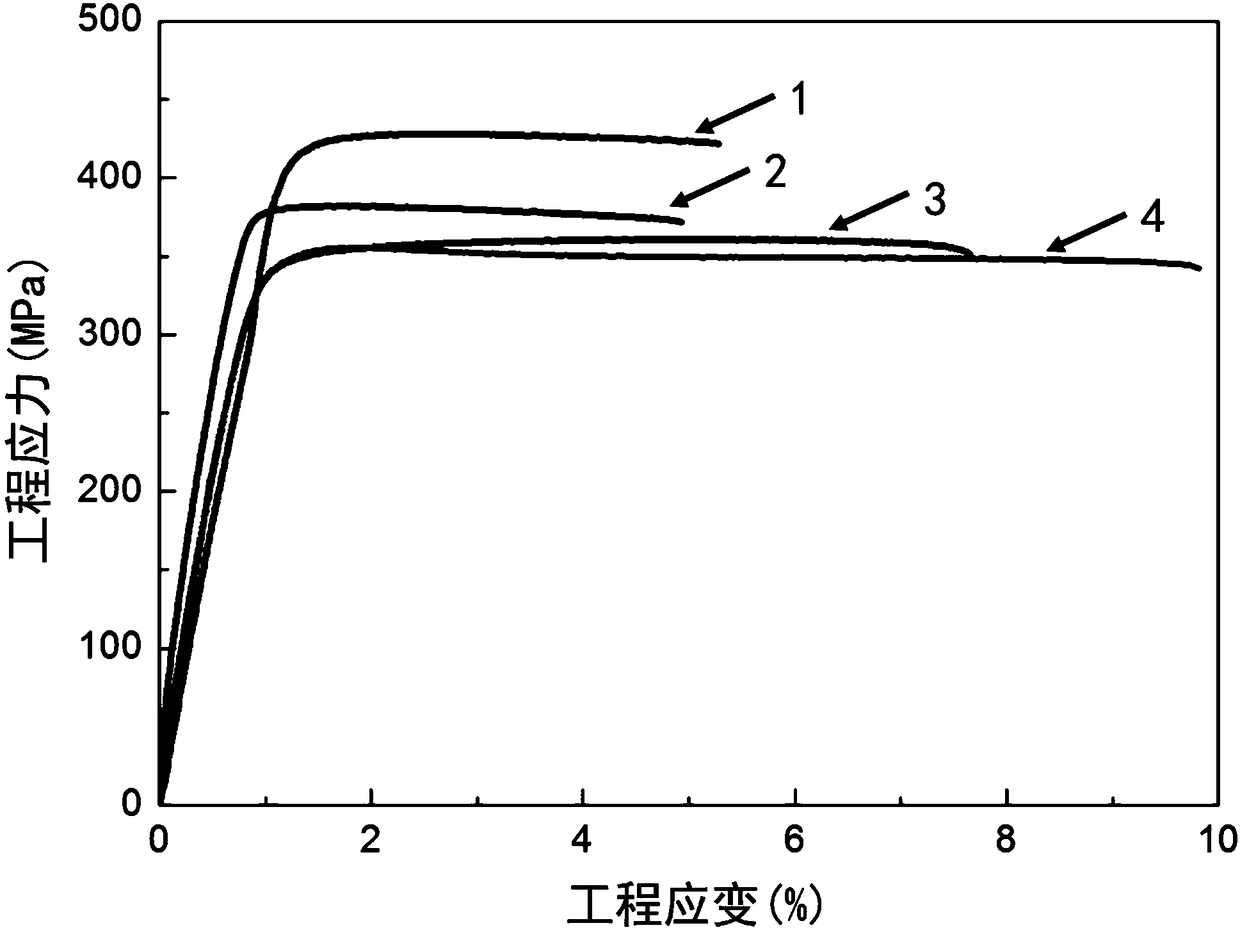

The invention provides a rare earth-free low-alloy super-high-toughness magnesium alloy and a preparation method thereof, relates to the fields of metal materials and metal material processing, and particularly relates to a magnesium alloy and a preparation method thereof. The invention aims to solve the problem of low yield strength of the existing magnesium alloy, and to provide a rare earth-free low-alloy super-high-toughness magnesium alloy and a preparation method thereof. The low-alloy super-high-toughness magnesium alloy is prepared from Mg and alloying elements, wherein the mass fraction of the alloying elements is equal to or less than 2.5%, and the balance of Mg; the alloying elements are composed of Al, Ca and Mn, or Al, Ca, Sr and Mn. The preparation method comprises the following steps: 1, smelting and casting to obtain a cast alloy; 2, performing homogenization treatment; 3, performing extrusion deformation to obtain the rare earth-free low-alloy super-high-toughness magnesium alloy. The advantages are as follows: the yield strength at the room temperature reaches up to 334 to 430 MPa, the tensile strength reaches 356 to 440 MPa, and the ductility is 5.0% or above. The preparation method provided by the invention is mainly used for preparing the rare earth-free low-alloy super-high-toughness magnesium alloy.

Owner:HARBIN INST OF TECH

A kind of high-strength plastic aluminum alloy and preparation method thereof

The invention relates to the technical field of metal materials and processing thereof, and discloses a high-strength plastic aluminum alloy and a preparation method thereof. The composition content of the aluminum alloy is as follows: the mass fraction of Cu is 5%-6%, and the mass fraction of Mg is 0.2%- 1.0%, the mass fraction of Ag is 0.2-0.5%, the mass fraction of Mn is 0.2-0.4%, and the mass fraction of alloy elements is ≤10%, and the balance is Al. By reasonably controlling the contents of Cu, Mg, Ag and Mn in the aluminum alloy, the aluminum alloy has both high strength and high plasticity. The preparation method: 1. melting and casting to obtain an aluminum alloy ingot; 2. homogenizing treatment; 3. extruding and deforming to obtain a high-strength and tough aluminum alloy. Its deformed mechanical properties such as strength, plasticity and toughness are superior to the traditional commercial deformed aluminum alloy 2D70, and its comprehensive mechanical properties in the as-cast state are superior to the traditional commercial cast aluminum alloy 2024, which is suitable for aerospace materials.

Owner:YANTAI NANSHAN UNIV

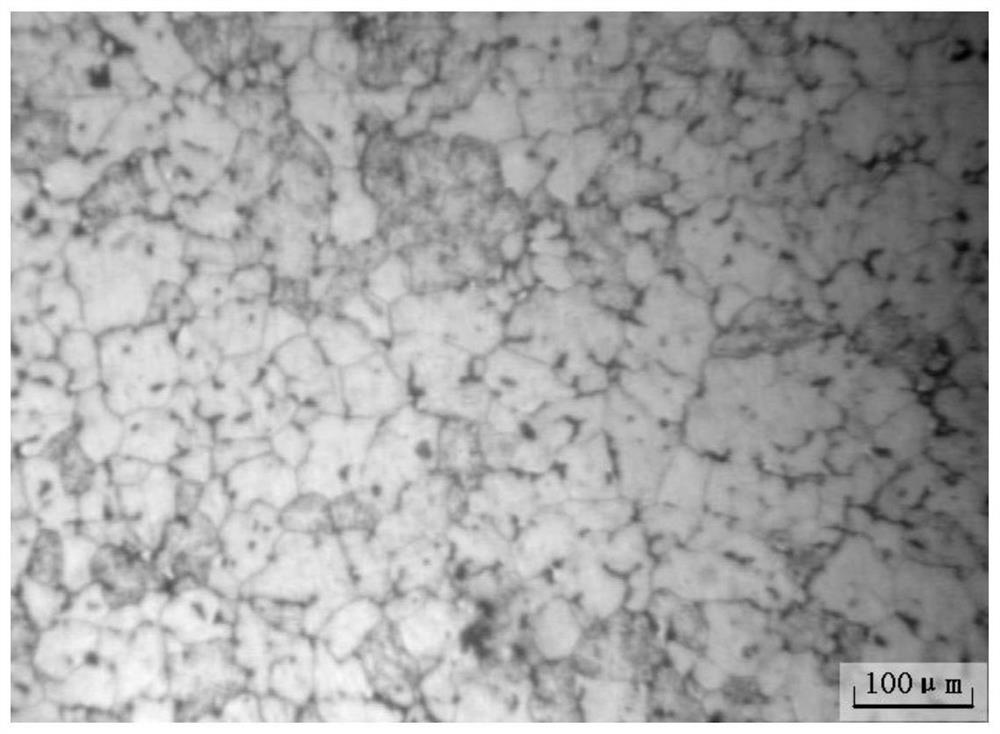

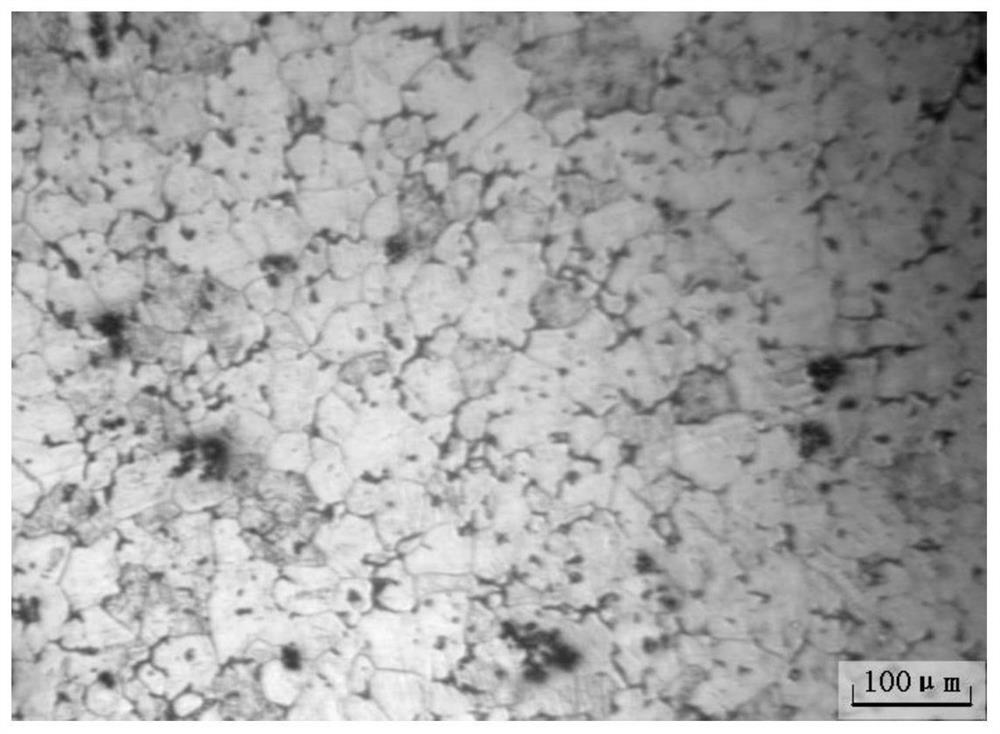

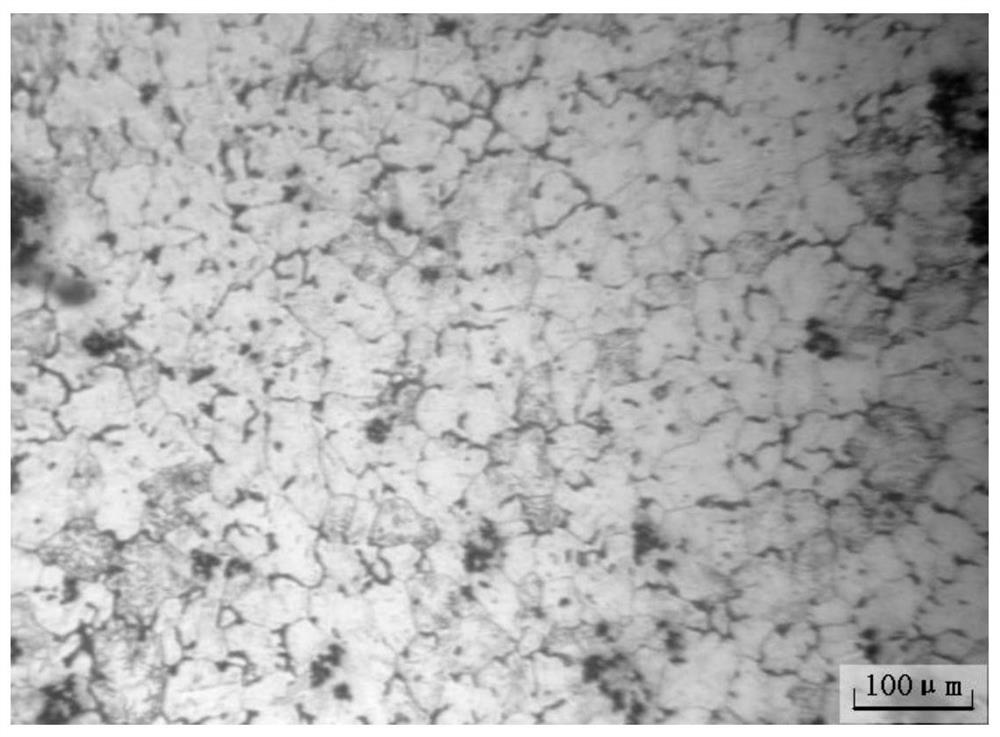

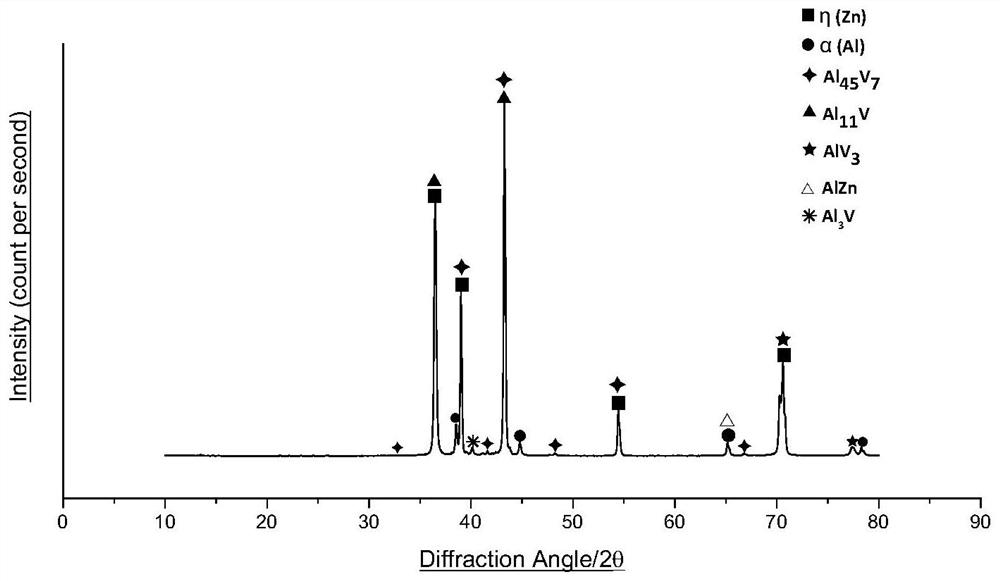

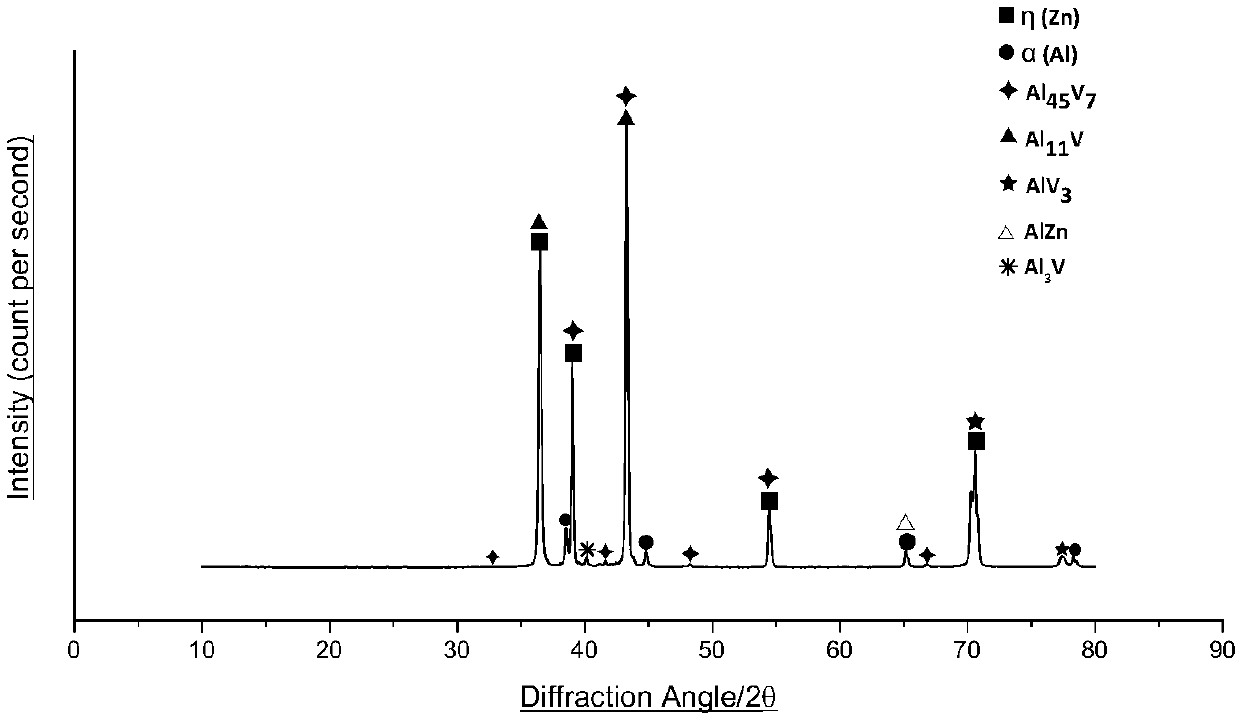

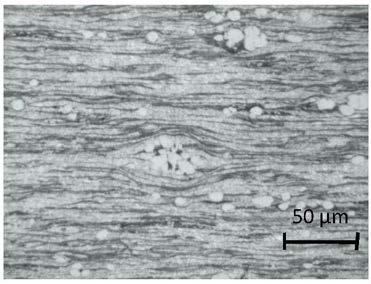

A heat treatment method for deformed zinc-aluminum-vanadium alloy

The invention belongs to the technical field of nonferrous metal material processing and particularly relates to a heat treatment method of transformation zinc-aluminum-vanadium alloy. According to the heat treatment method of the transformation zinc-aluminum-vanadium alloy, multi-pass repeated heat treatment containing splat cooling circular quenching is adopted, and in other words, when heat preservation is conducted on a zinc-aluminum-vanadium alloy semi-finished product obtained after hot and cold plastic working for 0.5-2.0 hours at the temperature of 100-190 DEG C, the zinc-aluminum-vanadium alloy semi-finished product is delivered out of a furnace for splat cooling quenching; then, the zinc-aluminum-vanadium alloy semi-finished product is reheated to 100-190 DEG C, heat preservationis conducted for 0.5-2.0 hours, and the zinc-aluminum-vanadium alloy semi-finished product is delivered out of the furnace for splat cooling quenching; and heat treatment is repeated by two or more cycles as above. The tensile strength, achieved at the room temperature, of the zinc-aluminum-vanadium alloy obtained after the special heat treatment mode exceeds 402 MPa; and the percentage elongation after fracture reaches 10% or above. Compared with a common heat treatment method, by means of the heat treatment method, the tensile strength of the zinc-aluminum-vanadium alloy is improved by 60%or above, and good plasticity is maintained. Therefore, the heat treatment method can achieve the quite good engineering value.

Owner:CENT SOUTH UNIV

Rare-earth-free low-alloy ultra-high-strength magnesium alloy and preparation method thereof

The invention provides a rare earth-free low-alloy super-high-toughness magnesium alloy and a preparation method thereof, relates to the fields of metal materials and metal material processing, and particularly relates to a magnesium alloy and a preparation method thereof. The invention aims to solve the problem of low yield strength of the existing magnesium alloy, and to provide a rare earth-free low-alloy super-high-toughness magnesium alloy and a preparation method thereof. The low-alloy super-high-toughness magnesium alloy is prepared from Mg and alloying elements, wherein the mass fraction of the alloying elements is equal to or less than 2.5%, and the balance of Mg; the alloying elements are composed of Al, Ca and Mn, or Al, Ca, Sr and Mn. The preparation method comprises the following steps: 1, smelting and casting to obtain a cast alloy; 2, performing homogenization treatment; 3, performing extrusion deformation to obtain the rare earth-free low-alloy super-high-toughness magnesium alloy. The advantages are as follows: the yield strength at the room temperature reaches up to 334 to 430 MPa, the tensile strength reaches 356 to 440 MPa, and the ductility is 5.0% or above. The preparation method provided by the invention is mainly used for preparing the rare earth-free low-alloy super-high-toughness magnesium alloy.

Owner:HARBIN INST OF TECH

A kind of preparation technology of fecrcomnni high entropy alloy matrix composite material

ActiveCN110257684BImprove performanceSimple organizational structureHigh entropy alloysUltimate tensile strength

The invention discloses a preparation process of a FeCrCoMnNi high-entropy alloy-based composite material, which is prepared by a discharge plasma sintering process of FeCrCoMnNi powder and nano-TiC powder. -9%. In the present invention, when the sintering temperature is 1000°C, the loading pressure is 50MPa, the holding time is 5min, and the addition amount of TiC is 7%, the performance of the FeCrCoMnNi high-entropy alloy matrix composite material obtained by spark plasma sintering is better, and the hardness, room temperature yield strength and 600°C high temperature yield strength are better. They are 1092.4HV, 979.7MPa, 563.6MPa respectively. TiC and the M formed by the reaction 23 C 6 The strengthening phase is evenly distributed in the FeCrCoMnNi high-entropy alloy matrix, which plays the role of dispersion strengthening.

Owner:HEFEI UNIV OF TECH

Heat treatment process for improving strength and plasticity of magnesium alloy

Owner:CHONGQING SUN MAGNESIUM COMPANY

A kind of nanoparticle reinforced ztc4 titanium alloy and preparation method thereof

The invention is applicable to the technical field of titanium alloys, and provides a nano particle reinforced ZTC4 titanium alloy and a preparation method thereof. The reinforced nano particles are nano TiC particles, which can be used to improve the strength of the ZTC4 titanium alloy. Specifically, the ZTC4 titanium alloy includes the following components in terms of mass percentage: Al 5.5% to 6.8%, V 3.5% to 4.5%, Ti 88.4% to 90.99%, nano TiC particles 0.01% to 0.3%, and the balance is impurities Elements, the sum of the mass percentages of each component is 100%. In the present invention, by adding nano TiC particles in the ZTC4 titanium alloy, the strength of the ZTC4 titanium alloy is significantly improved unexpectedly, and can ensure that the elongation of the ZTC4 titanium alloy does not change greatly, which is very important for realizing the ZTC4 titanium alloy in the ZTC4 titanium alloy. Applications in high-strength environments are of great significance.

Owner:JILIN UNIV

A kind of nanoparticle toughened ztc4 titanium alloy and preparation method thereof

The invention is applicable to the technical field of titanium alloys, and provides a nano-particle toughened ZTC4 titanium alloy and a preparation method thereof. The toughened nano-particles include nano-TiC and nano-TiB 2 , and nano-TiC and nano-TiB 2 The molar ratio is 1:(1~3). The casting alloy comprises the following components: 5.5%-6.8% of Al, 3.5%-4.5% of V, 88.4%-90.99% of Ti, and 0.01%-0.3% of strengthening and toughening nanoparticles. The present invention adds toughening nano-TiC and nano-TiB 2 The particles obtained unexpected effects: with and without adding nano-TiC and nano-TiB 2 Compared with the ZTC4 titanium alloy with particles, the tensile strength, yield strength and elongation of the ZTC4 titanium alloy added with nanoparticles are all improved at the same time, especially the elongation is significantly improved, which has great significance for the application of ZTC4 titanium alloy in complex environments. Great significance.

Owner:JILIN UNIV

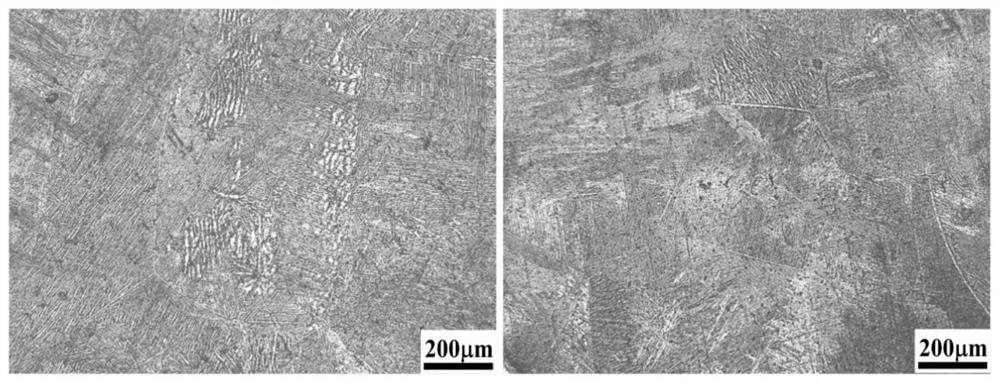

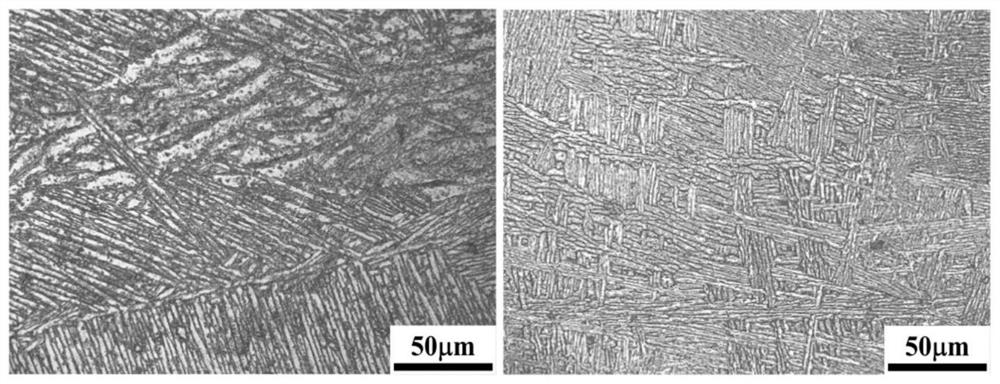

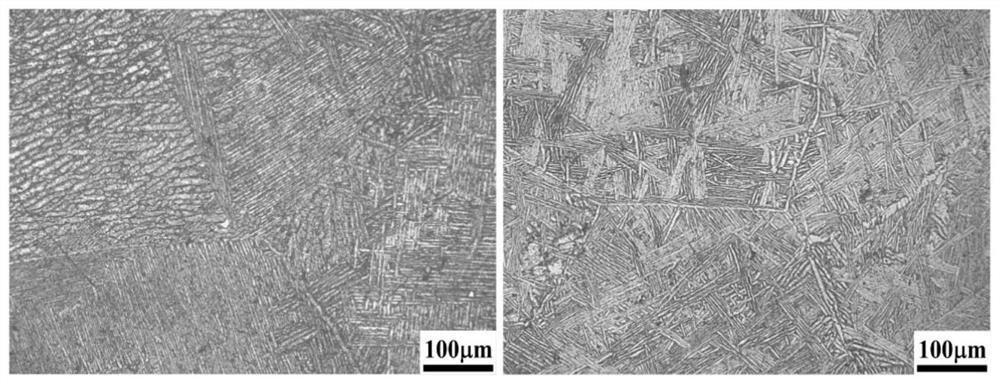

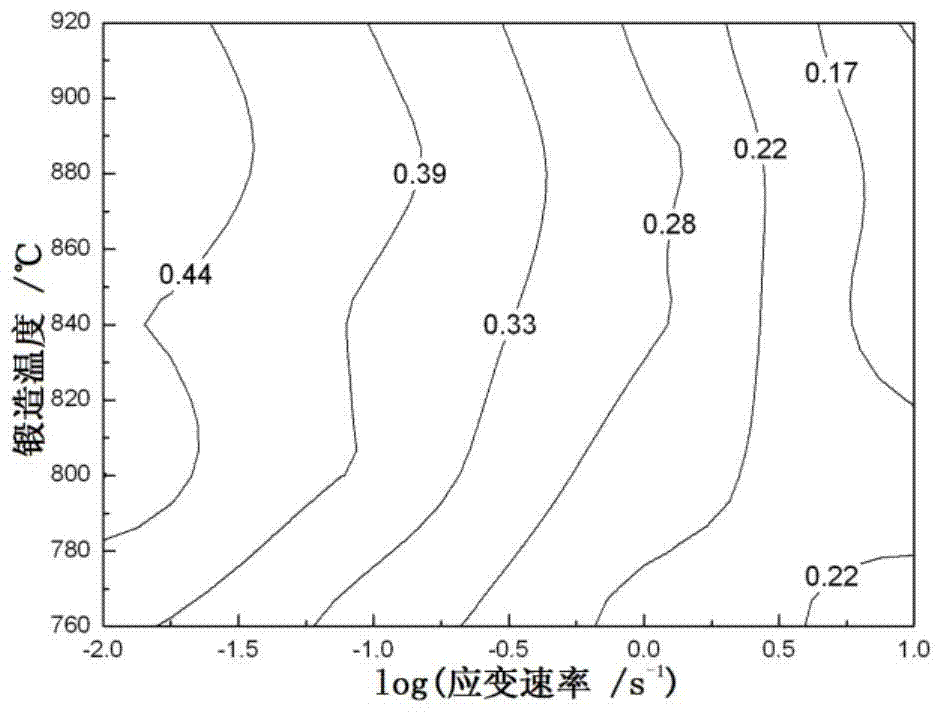

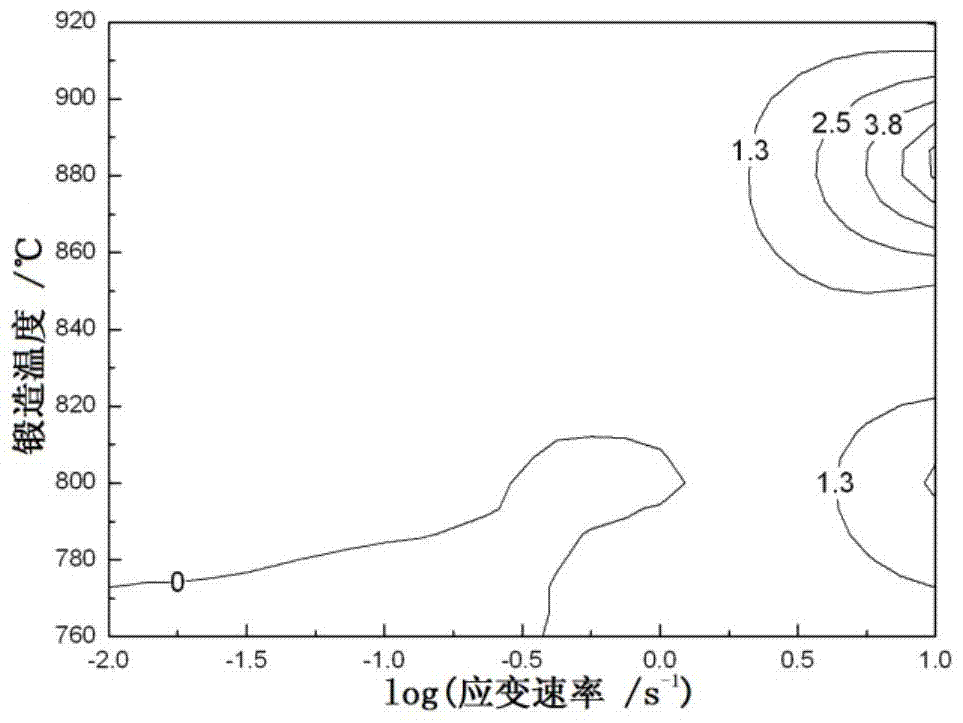

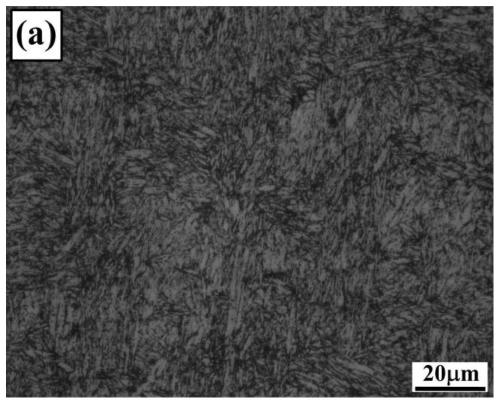

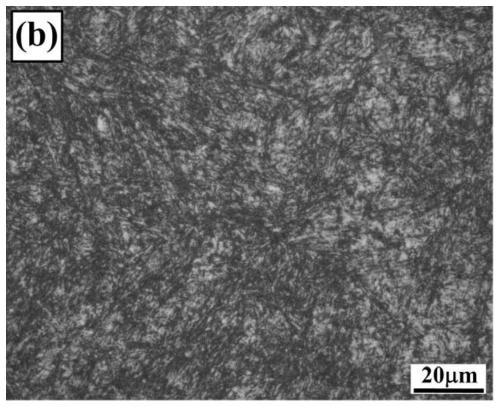

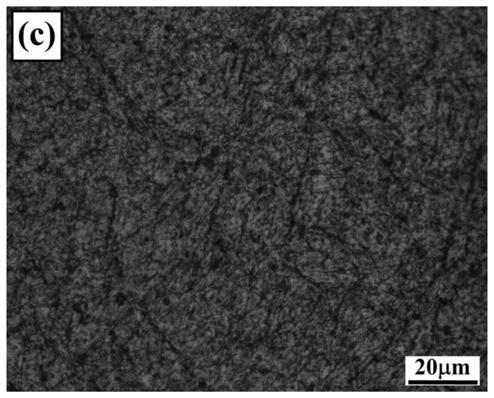

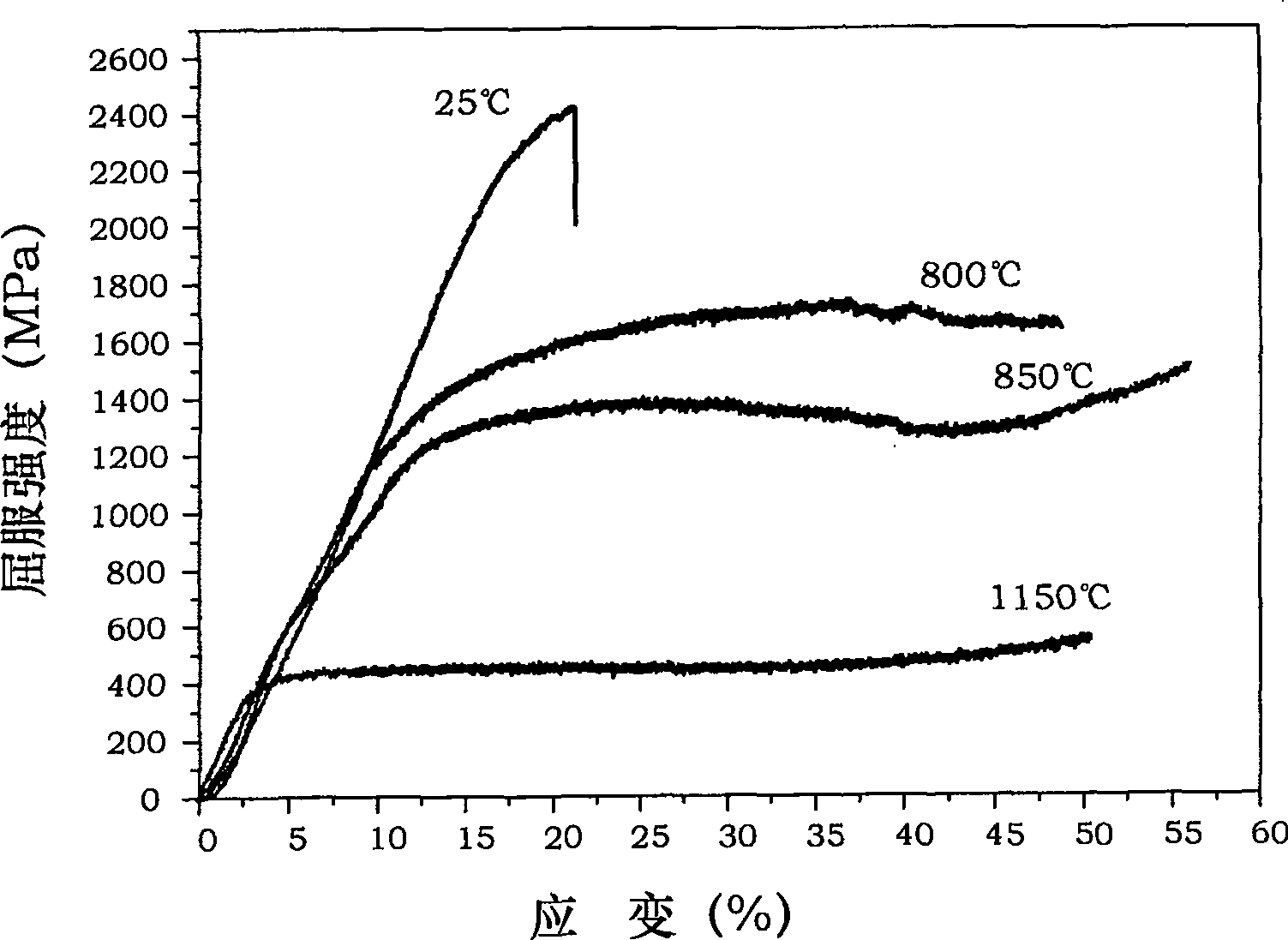

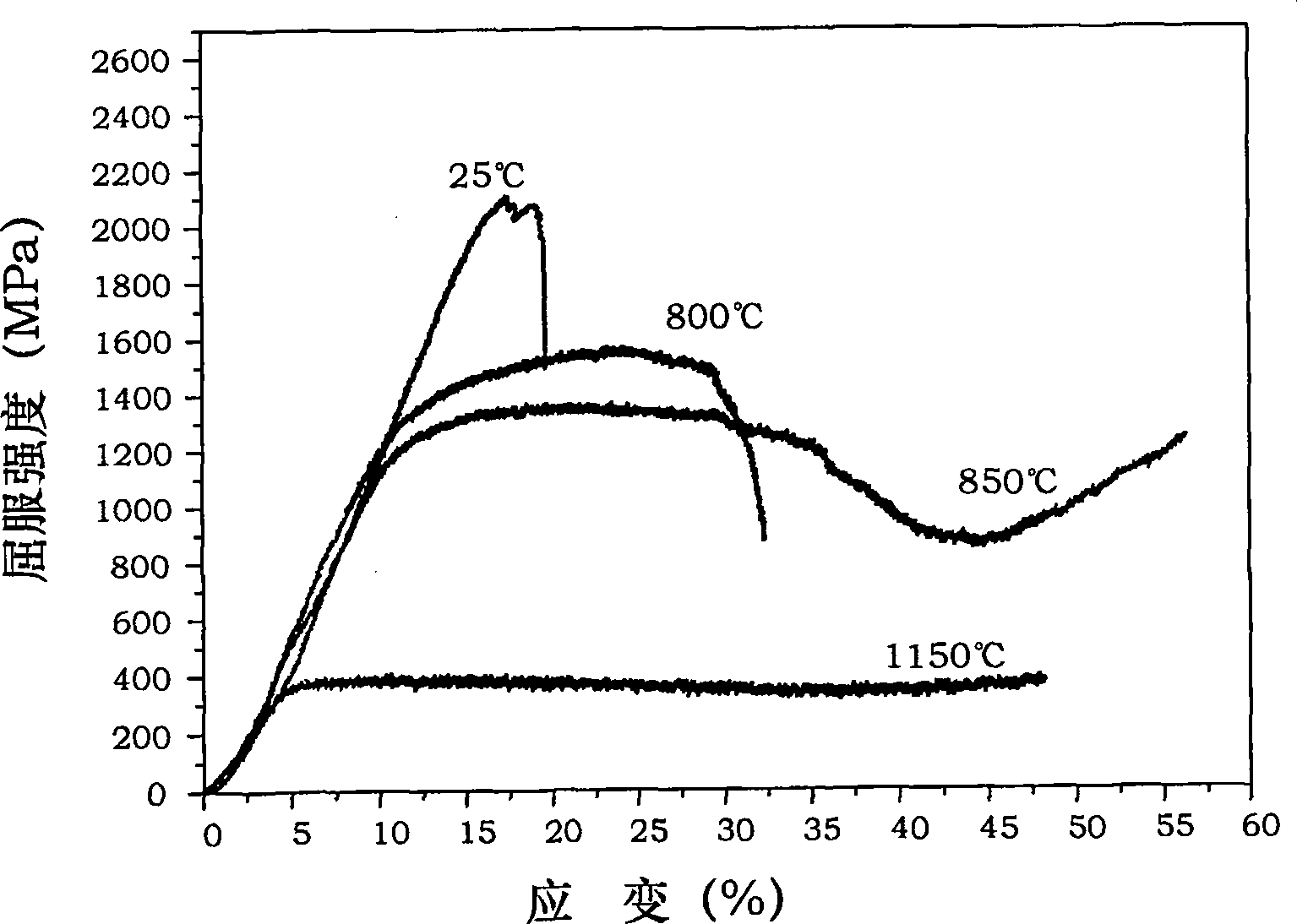

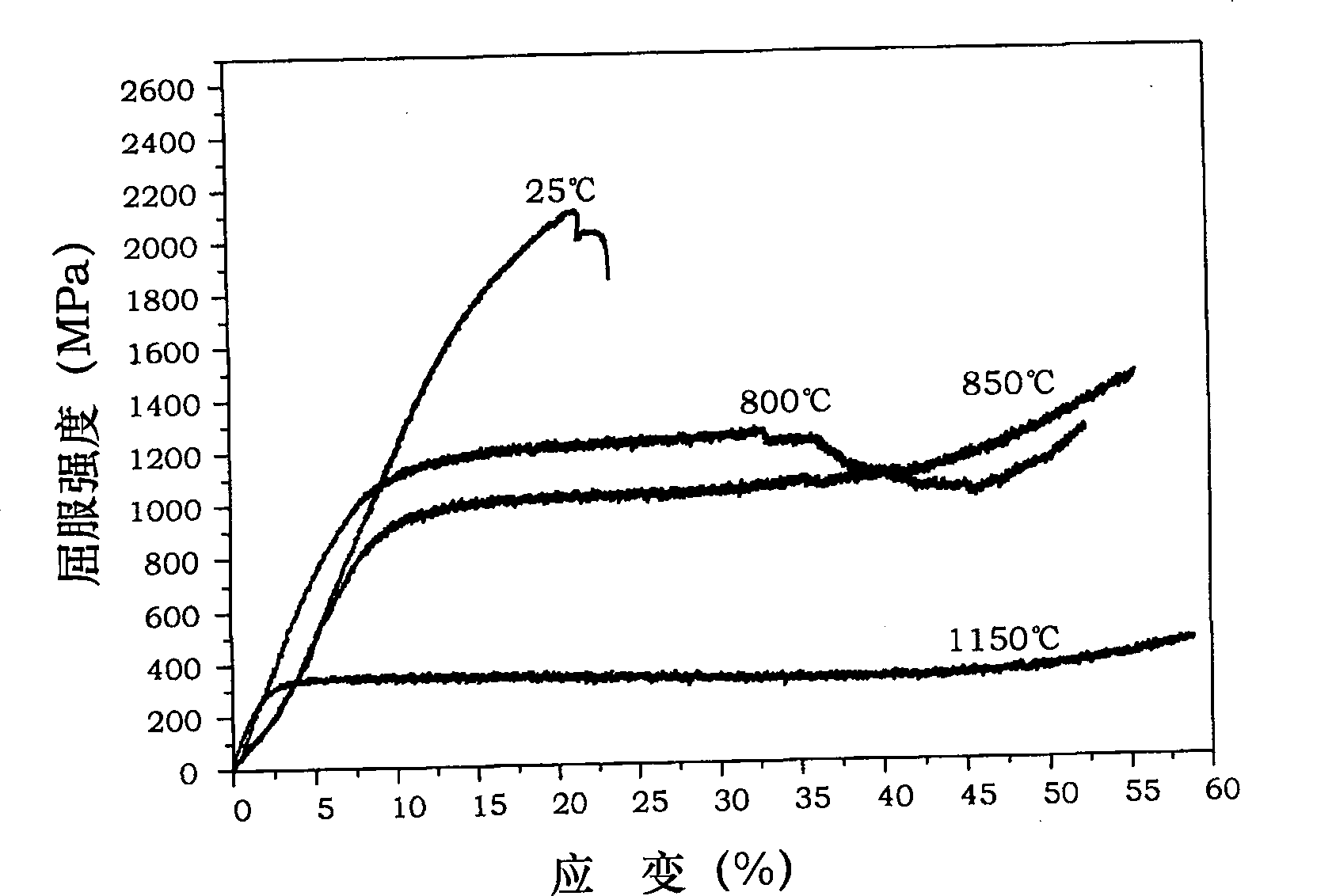

Optimization Method of Forging Process Parameters for Hydrogenated tc4 Titanium Alloy

ActiveCN105562573BIncreased tensile strength at room temperatureIncreased yield strength at room temperatureMetal-working apparatusFlow stressHydrogen content

Owner:南京三航智能制造科技有限公司

Iron-based bulk metallic glass alloy with large supercooled liquid phase region

Owner:DALIAN UNIV OF TECH

High Cr Cast Roadheader Tool Steel and Its Manufacturing Process

ActiveCN107881435BHigh strengthImprove red hardnessFurnace typesHeat treatment furnacesChemical compositionThermal fatigue

The invention relates to high-Cr-content cast heading machine cutter steel. The cutter steel comprises the chemical components of, by weight, 0.30%-0.55% of C, 8.0%-12.0% of Cr, 1.2%-3.0% of Mo, 0.5%-1.8% of Ni, 0.6%-1.0% of V, 0.1%-0.4% of Mn, 0.6%-0.8% of Si, 0.04%-0.30% of N, no more than 0.005% of S, no more than 0.03% of P and the balance Fe. The cutter steel manufacturing technique comprisesthe following steps that a near-net shape blank of a cutter is obtained through precise casting, then heat treatment is conducted, and a finished product is obtained directly after fine machining. Yield strength and tensile strength are improved while the hardness, impact toughness and elongation of the cutter steel all can reach the level of domestic forged heading machine cutter steel; the oxidation corrosion resistant capability, thermal fatigue resistant performance and abrasive grain abrasion resistance are improved; and the production period is shortened, and the production cost is reduced.

Owner:JILIN UNIV

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Hf

InactiveCN100523247CImprove high temperature strengthImprove performanceRoom temperatureUltimate tensile strength

The invention discloses a Hf-modified NiAl-Cr(Mo) dual-phase eutectic intermetallic compound, the composition range of which is 33at% Ni, 30at% Cr, 4at% Mo, 0.1-11at% Hf and The balance of Al. The NiAl-Cr(Mo) dual-phase eutectic alloy is modified by reducing the content of Al element and adding Hf element in the composition range near the eutectic point of NiAl-Cr(Mo) dual-phase eutectic alloy. Hf element and NiAl The Heusler (L21-Ni2AlHf) phase is formed, and the Heusler phase is introduced on the basis of the Ni-rich NiAl-Cr (Mo) two-phase structure with good room temperature plasticity and toughness to further improve the high-temperature strength of the eutectic intermetallic compound. The yield strength of the Hf-modified NiAl-Cr(Mo) dual-phase eutectic intermetallic compound at 1150 DEG C is 300-420MPa and the density is 6.02-7.66g / cm3.

Owner:BEIHANG UNIV

Heat treatment method of transformation zinc-aluminum-vanadium alloy

The invention belongs to the technical field of nonferrous metal material processing and particularly relates to a heat treatment method of transformation zinc-aluminum-vanadium alloy. According to the heat treatment method of the transformation zinc-aluminum-vanadium alloy, multi-pass repeated heat treatment containing splat cooling circular quenching is adopted, and in other words, when heat preservation is conducted on a zinc-aluminum-vanadium alloy semi-finished product obtained after hot and cold plastic working for 0.5-2.0 hours at the temperature of 100-190 DEG C, the zinc-aluminum-vanadium alloy semi-finished product is delivered out of a furnace for splat cooling quenching; then, the zinc-aluminum-vanadium alloy semi-finished product is reheated to 100-190 DEG C, heat preservationis conducted for 0.5-2.0 hours, and the zinc-aluminum-vanadium alloy semi-finished product is delivered out of the furnace for splat cooling quenching; and heat treatment is repeated by two or more cycles as above. The tensile strength, achieved at the room temperature, of the zinc-aluminum-vanadium alloy obtained after the special heat treatment mode exceeds 402 MPa; and the percentage elongation after fracture reaches 10% or above. Compared with a common heat treatment method, by means of the heat treatment method, the tensile strength of the zinc-aluminum-vanadium alloy is improved by 60%or above, and good plasticity is maintained. Therefore, the heat treatment method can achieve the quite good engineering value.

Owner:CENT SOUTH UNIV

Nanoparticle toughened ZTC4 titanium alloy and preparation method thereof

The invention is applicable to the technical field of titanium alloys, and provides a nanoparticle toughened ZTC4 titanium alloy and a preparation method thereof. Toughened nanoparticles comprise nanoTiC and nano TiB2, and the molar ratio of the nano TiC to the nano TiB2 is 1: (1-3). The casting alloy comprises the following components in percentage by weight: 5.5%-6.8% of Al, 3.5%-4.5% of V, 88.4%-90.99% of Ti and 0.01%-0.3% of the toughened nanoparticles. By adding the toughened nano TiC and nano TiB2 particles, an unexpected effect is achieved: compared with ZTC4 titanium alloy without thenano TiC or nano TiB2 particles, the tensile strength, the yield strength and the elongation of the ZTC4 titanium alloy added with the nano particles are improved at the same time, and particularly,the elongation is remarkably improved. The nanoparticle toughened ZTC4 titanium alloy and the preparation method thereof have great significance in application of the ZTC4 titanium alloy in a complexenvironment.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com