Nanoparticle toughened ZTC4 titanium alloy and preparation method thereof

A nanoparticle, ZTC4 technology, applied in the field of titanium alloys, can solve the problems of not meeting the requirements of strong plasticity and no significant effect of strengthening and toughening titanium alloys, and achieve the effect of increasing strength, high strength and toughness, and increasing elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

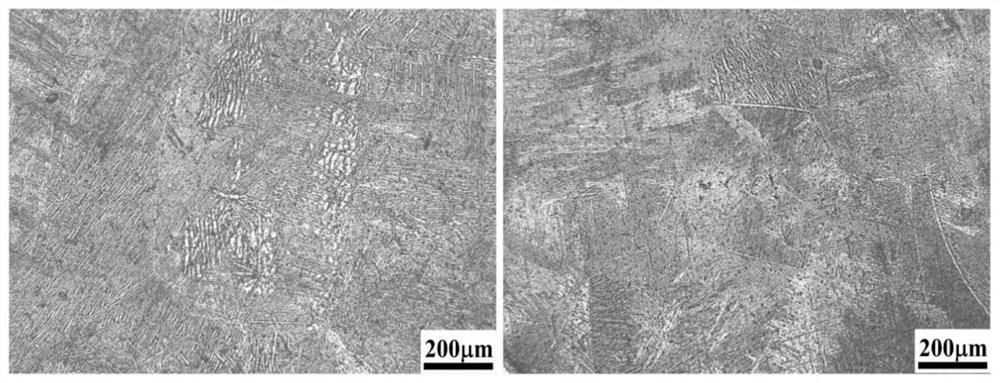

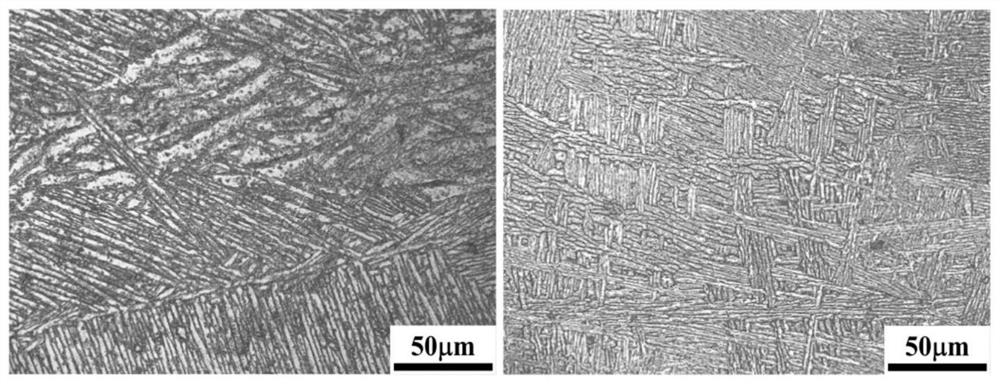

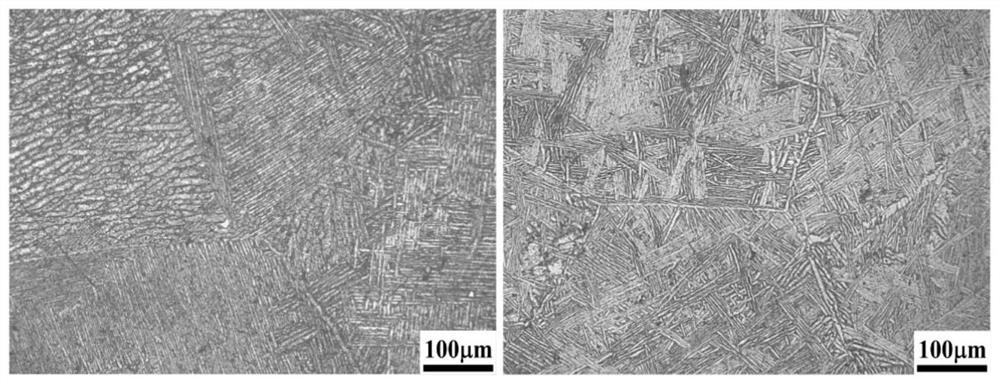

Image

Examples

Embodiment 1

[0031] This embodiment provides a kind of ZTC4 titanium alloy, and its preparation method comprises the following steps:

[0032] S1, the Nano B 4 C powder and titanium powder with a particle size of 300 mesh are mixed according to a molar ratio of 1:3 to obtain a mixture; then, the mixture and aluminum powder with a particle diameter of 500 mesh are placed in a ball mill at a mass ratio of 30:70 at 50 Mix at a speed of 1 rpm for 24 hours to obtain alloy powder.

[0033] S2. Put the above alloy powder in aluminum foil, press it into a cylindrical compact with a diameter of 25 mm and a height of 35 mm, then put the compact into a graphite mold, and place the graphite mold in a vacuum heating furnace at 30 °C / min The heating rate is heated to 930°C for 10 minutes of heat preservation treatment, and then cooled to room temperature with the furnace to obtain nano-TiC and nano-TiB 2 Aluminum-based master alloy, wherein the particle size of nano-TiC is 60-120nm, nano-TiB 2 The pa...

Embodiment 2

[0040] This embodiment provides a kind of ZTC4 titanium alloy, and its preparation method comprises the following steps:

[0041] S1, the Nano B 4 C powder and titanium powder with a particle size of 300 mesh are mixed according to a molar ratio of 1:3 to obtain a mixture; then, the mixture and aluminum powder with a particle diameter of 500 mesh are placed in a ball mill at a mass ratio of 30:70 at 50 Mix at a speed of 1 rpm for 24 hours to obtain alloy powder.

[0042] S2. Put the above alloy powder in aluminum foil, press it into a cylindrical compact with a diameter of 25mm and a height of 35mm, then put the compact into a graphite mold, and place the graphite mold in a vacuum heating furnace at 30°C / min The heating rate is heated to 930°C for 10 minutes of heat preservation treatment, and then cooled to room temperature with the furnace to obtain nano-TiC and nano-TiB 2 Aluminum-based master alloy, wherein the particle size of nano-TiC is 60-120nm, nano-TiB 2 The parti...

Embodiment 3

[0049] This embodiment provides a kind of ZTC4 titanium alloy, and its preparation method comprises the following steps:

[0050] S1, the Nano B 4 C powder and titanium powder with a particle size of 300 mesh are mixed according to a molar ratio of 1:3 to obtain a mixture; then, the mixture and aluminum powder with a particle diameter of 500 mesh are placed in a ball mill at a mass ratio of 30:70 at 50 Mix at a speed of 1 rpm for 24 hours to obtain alloy powder.

[0051] S2. Put the above alloy powder in aluminum foil, press it into a cylindrical compact with a diameter of 25mm and a height of 35mm, then put the compact into a graphite mold, and place the graphite mold in a vacuum heating furnace at 30°C / min The heating rate is heated to 930°C for 10 minutes of heat preservation treatment, and then cooled to room temperature with the furnace to obtain nano-TiC and nano-TiB 2 Aluminum-based master alloy, wherein the particle size of nano-TiC is 60-120nm, nano-TiB 2 The parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com