A heat treatment method for deformed zinc-aluminum-vanadium alloy

A technology of zinc-aluminum-vanadium alloy and heat treatment method, which is applied in the field of non-ferrous metal material processing, can solve the problems of low comprehensive performance of deformed zinc-aluminum alloys, and achieve the effects of increased yield strength, broad application prospects, and increased elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

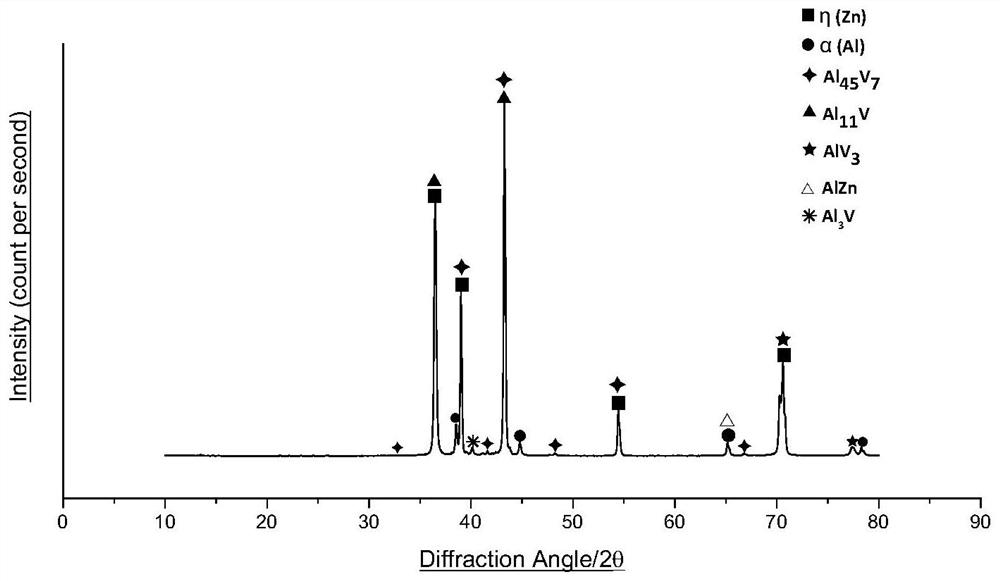

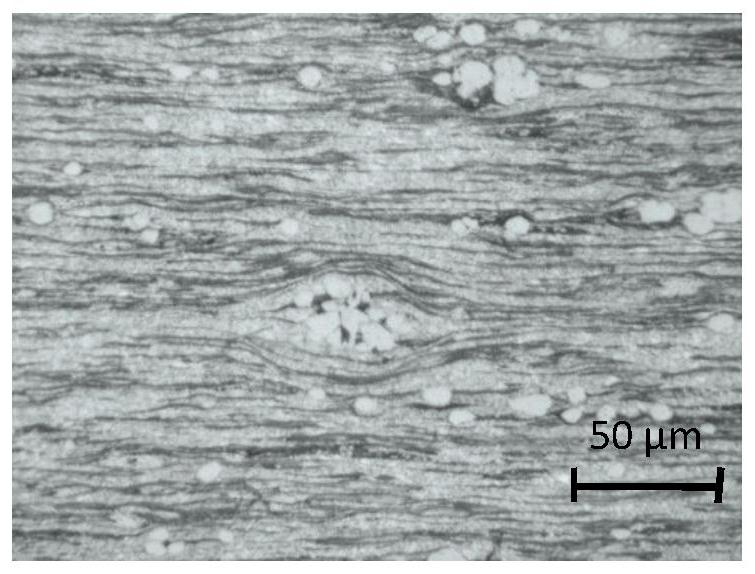

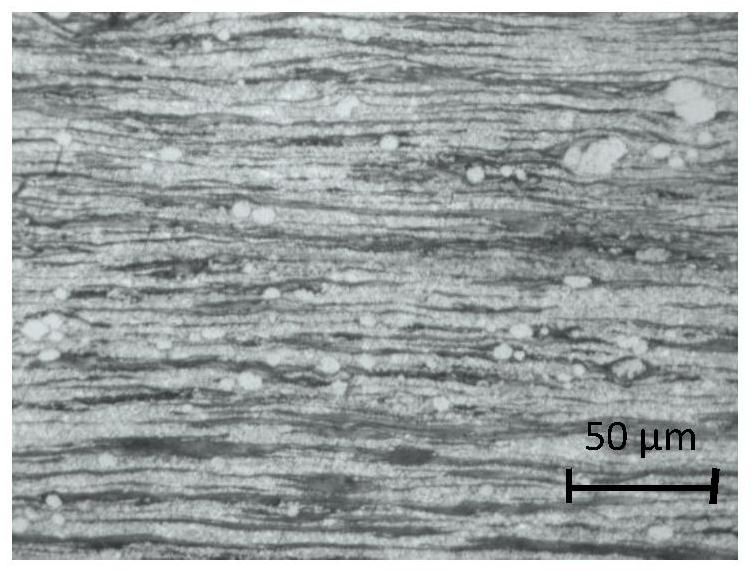

Image

Examples

Embodiment 1

[0043]1. Heat treatment process of deformed zinc-vanadium aluminum alloy

[0044]The alloy after homogenization treatment and hot and cold plastic deformation treatment is quenched and heat treated by 4 times of ice water quenching cycle:

[0045](100~120℃)×30min×Quick quenching(≥35℃ / S)+(100~120℃)×30min×Quick quenching(≥35℃ / S)+(100~120℃)×30min×Quick quenching( ≥35℃ / S)+(100~120℃)×30min×quick quenching (≥35℃ / S)

[0046]2. Room temperature tensile test

[0047]The mechanical properties of the finally obtained zinc-vanadium aluminum alloy were tested. The result is:

[0048]

Embodiment 2

[0050]1. Heat treatment process of deformed zinc-vanadium aluminum alloy

[0051]The alloy after homogenization treatment and hot and cold plastic deformation treatment is quenched and heat treated by 4 times of ice water quenching cycle:

[0052](120~140℃)×60min×Quick quenching(≥55℃ / S)+(120~140℃)×60min×Quick quenching(≥55℃ / S)+(120~140℃)×60min×Quick quenching( ≥55℃ / S)+(120~140℃)×60min×quick quenching (≥55℃ / S)

[0053]2. Room temperature tensile test

[0054]The mechanical properties of the finally obtained zinc-vanadium aluminum alloy were tested. The result is:

[0055]

Embodiment 3

[0057]1. Heat treatment process of deformed zinc-vanadium aluminum alloy

[0058]The alloy after homogenization treatment and hot and cold plastic deformation treatment is quenched and heat treated by 4 times of ice water quenching cycle:

[0059](140~160℃)×90min×Quick quenching(≥75℃ / S)+(140~160℃)×90min×Quick quenching(≥75℃ / S)+(140~160℃)×90min×Quick quenching( ≥75℃ / S)+(140~160℃)×90min×quick quenching (≥75℃ / S)

[0060]2. Room temperature tensile test

[0061]The mechanical properties of the finally obtained zinc-vanadium aluminum alloy were tested. The result is:

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com