Nano twin crystal copper material with ultrahigh strength and superhigh conductivity as well as preparation method

A nano-twinned copper, ultra-high-strength technology, applied in the field of ultra-high conductivity nano-twinned copper materials and preparation, ultra-high strength, can solve the problem of limited yield strength of pure Cu materials, and achieve excellent properties and high electrical conductivity , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

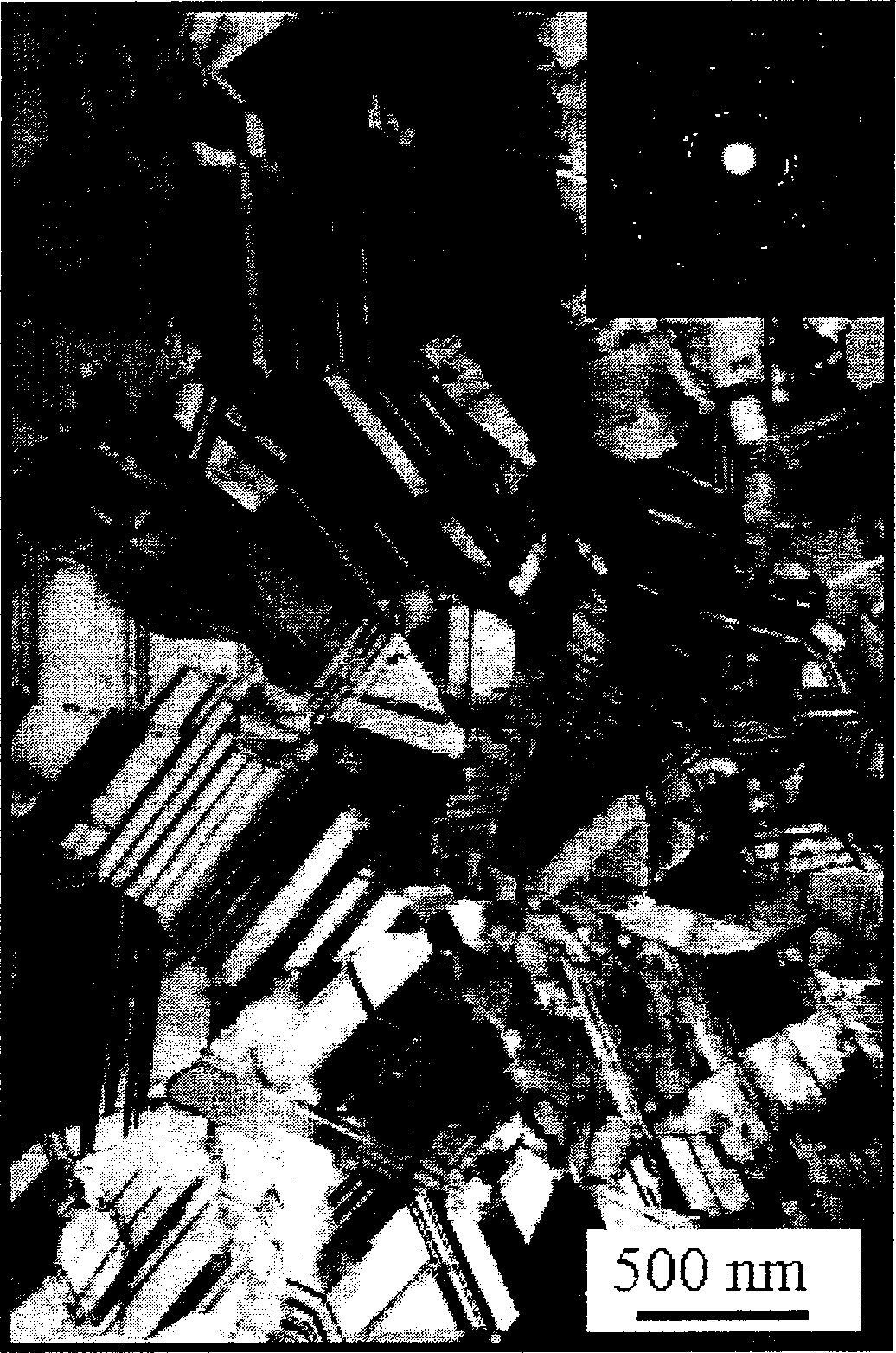

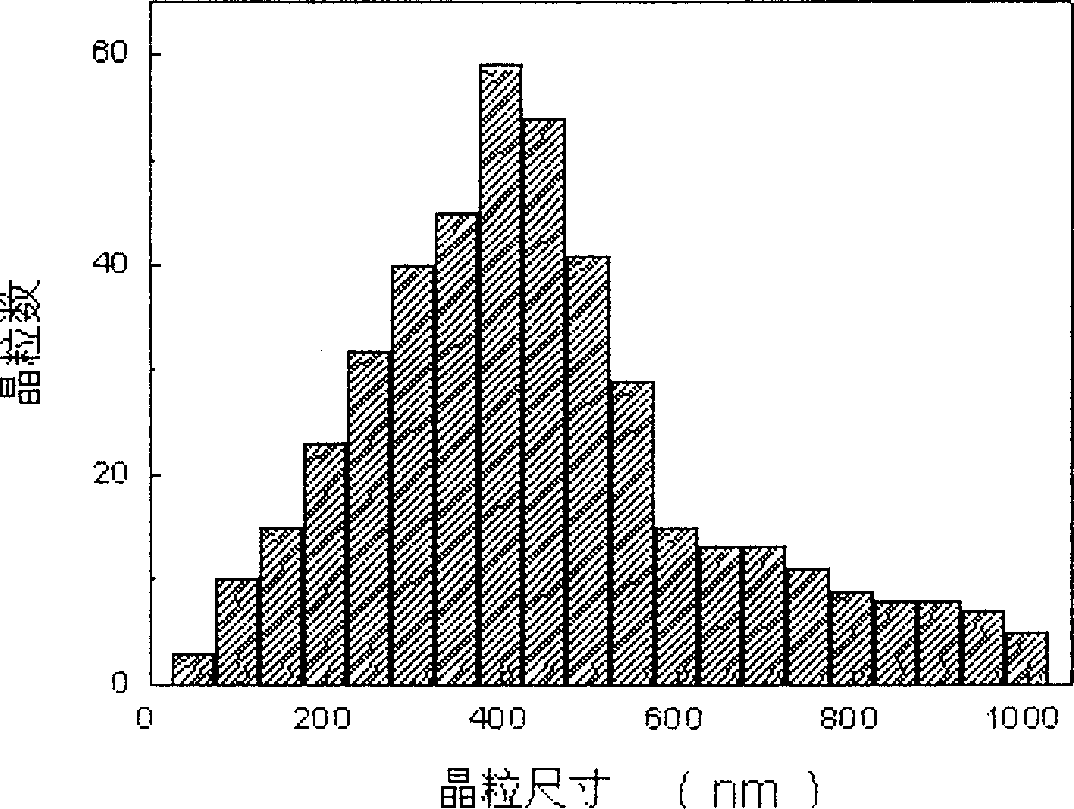

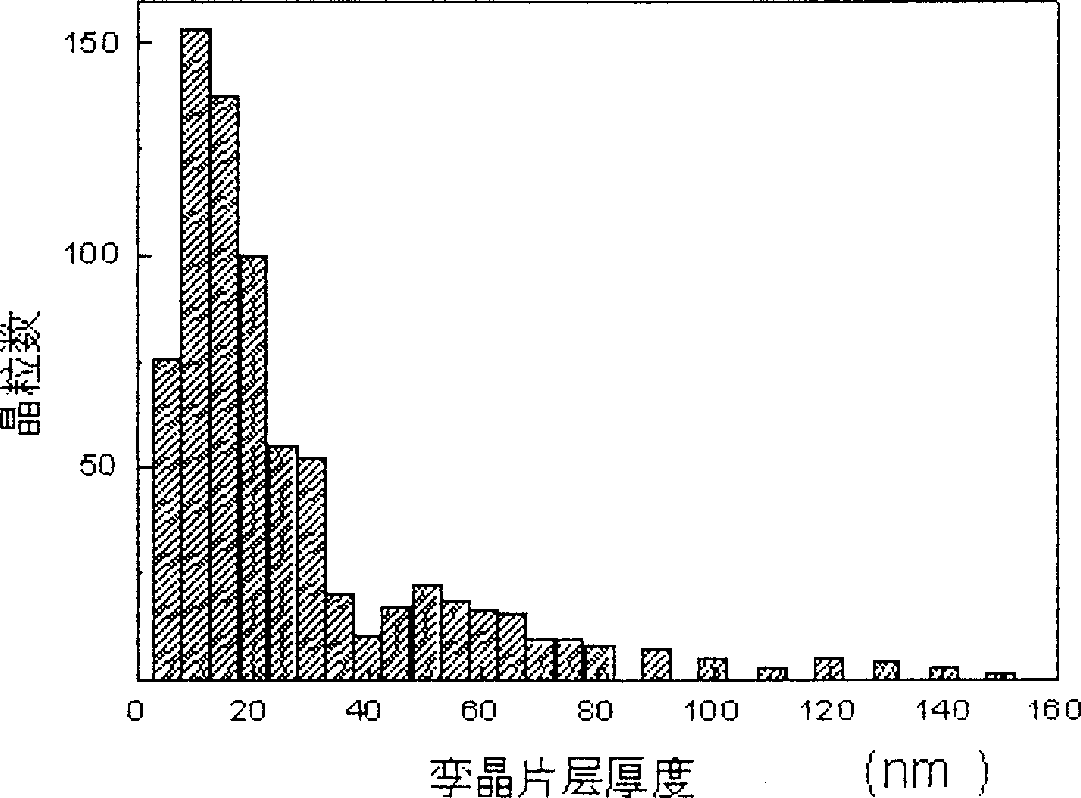

[0030] 1. Preparation of flaky nano-twin crystal Cu material by electrolytic deposition technology

[0031] Electrolytic deposition equipment: single pulse electrolytic deposition equipment

[0032] Electrolyte requirements for electrolytic deposition: electronically pure CuSO 4 Solution, strictly control the content of heavy metal impurities in the electrolyte, the water used for distributing the electrolyte should be high-purity deionized water, and the acidity of the electrolyte is: PH=1.

[0033] Requirements for cathode and anode: the anode is a pure copper plate with a purity higher than 99.99%, and the cathode is an iron plate coated with Ni-P amorphous layer.

[0034] 2. Electrolysis process parameters: pulse current density is 50A / cm 2 , pulse plating; conduction time (t on ) is 0.02s, closing time (t off ) is 2s, the distance between cathode and anode is 100mm, the area ratio of anode and cathode is 50:1; the electrolysis temperature is 20C, and the electrolytic ...

Embodiment 2

[0048] The difference from Example 1 is:

[0049] 1) Preparation of flaky nanocrystalline Cu materials by electrolytic deposition technology: Electron-grade high-purity copper sulfate CuSO for electrolyte 4 solution, add high-purity distilled water, and the acidity is PH=0.5; Yin and anode: the anode is a pure copper plate with a purity higher than 99.99%, and the cathode is an iron plate with a Ni-P amorphous layer on the surface, and the anode-to-cathode area ratio is 30 : 1.

[0050] 2) Additives: 0.02ml / l of gelatin aqueous solution with 5% concentration, 0.2ml / l of high-purity NaCl aqueous solution with 5% concentration; electrolysis process parameters: pulse current density is 80A / cm 2 , on-time (t on ) is 0.05s, the closing time (t off ) is 3s; the distance between cathode and anode is 50mm, and the temperature of electrolyte is 15℃;

[0051] High-purity, high-density, thin-sheet twinned nanocrystalline Cu materials can also be prepared under this process condition....

Embodiment 3

[0053] The difference from Example 1 is:

[0054] 1) Preparation of thin flaky nanocrystalline Cu materials by electrolytic deposition technology: electronically pure copper sulfate CuSO for electrolyte 4 Solution, add high-purity distilled water, acidity is PH=1.5; Yin, anode: the anode is a pure copper plate with a purity higher than 99.99%, and the cathode is a low-carbon steel plate with a Ni-P amorphous layer on the surface, and the anode-to-cathode area ratio is 40 : 1.

[0055] 2) Additives: 0.15ml / l of gelatin aqueous solution with 25% concentration, 1.0ml / l of high-purity NaCl aqueous solution with 25% concentration; electrolysis process parameters: pulse current density is 40A / cm 2 , on-time (t on ) is 0.01s, closing time (t off ) is 1s; the pole distance between cathode and anode is 150mm, and the electrolysis temperature is 25°C;

[0056] Under the process conditions, high-purity, high-density, thin-sheet twinned nanocrystalline Cu materials can also be prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com