A kind of high-strength plastic aluminum alloy and preparation method thereof

An aluminum alloy, high-strength technology, applied in the field of high-strength plastic aluminum alloy and its preparation, can solve the problems of increasing the workload of support personnel and equipment maintenance costs, endangering flight safety, affecting tasks, etc., and achieves abundant raw material reserves, low prices, and costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A high-strength plastic aluminum alloy, including Cu, Mg, Ag, and Mn elements, the mass percentage content of each element in the aluminum alloy is: Cu is 5% to 6%, Mg is 0.2% to 1.0%, and Ag is 0.2% to 0.5%, Mn is 0.2-0.4%, and the balance is Al.

[0024] The high-strength plastic aluminum alloy in this embodiment is specifically completed according to the following steps:

[0025] S1. Alloy smelting and casting: according to the aluminum alloy in which Cu is 5%-6%, Mg is 0.2%-1.0%, Ag is 0.2-0.5%, Mn is 0.2-0.4%, and the balance is Al, weigh an appropriate amount of pure Al, pure Mg and Al-20wt% Cu, Al-20wt% Ag and Al-10wt% Mn master alloy; The master alloy is separated and preheated at 160°C for 15-30 minutes; heat the pure aluminum in a resistance furnace, keep it at 680-760°C to melt the masterbatch, and then add the preheated pure Mg, Al-20wt% Cu, Al -20wt% Ag and Al-10wt% Mn master alloy, heat up to 680-760°C and keep it warm for 15-30 minutes, wait until the a...

Embodiment 2

[0032] In this example, a high-strength plastic aluminum alloy was prepared and tested according to the following steps:

[0033] 1. Casting: According to the mass fraction of Cu in the aluminum alloy is 5%, the mass fraction of Mg is 0.2%, the mass fraction of Ag is 0.2%, the mass fraction of Mn is 0.2%, and the balance is Al. Weigh an appropriate amount of pure Al, pure Mg and Al-20wt% Cu, Al-20wt% Ag and Al-10wt% Mn master alloys; Al is completely melted, then add pure Mg, Al-Cu master alloy, Al-Ag master alloy, Al-Mn master alloy in turn, at a temperature of 760°C, mechanically stir for 15 minutes, then cool down to 700°C and stand for 15 minutes to obtain alloy melt body, cast into an iron mold at 300°C to obtain an aluminum alloy ingot, and air-cool to room temperature.

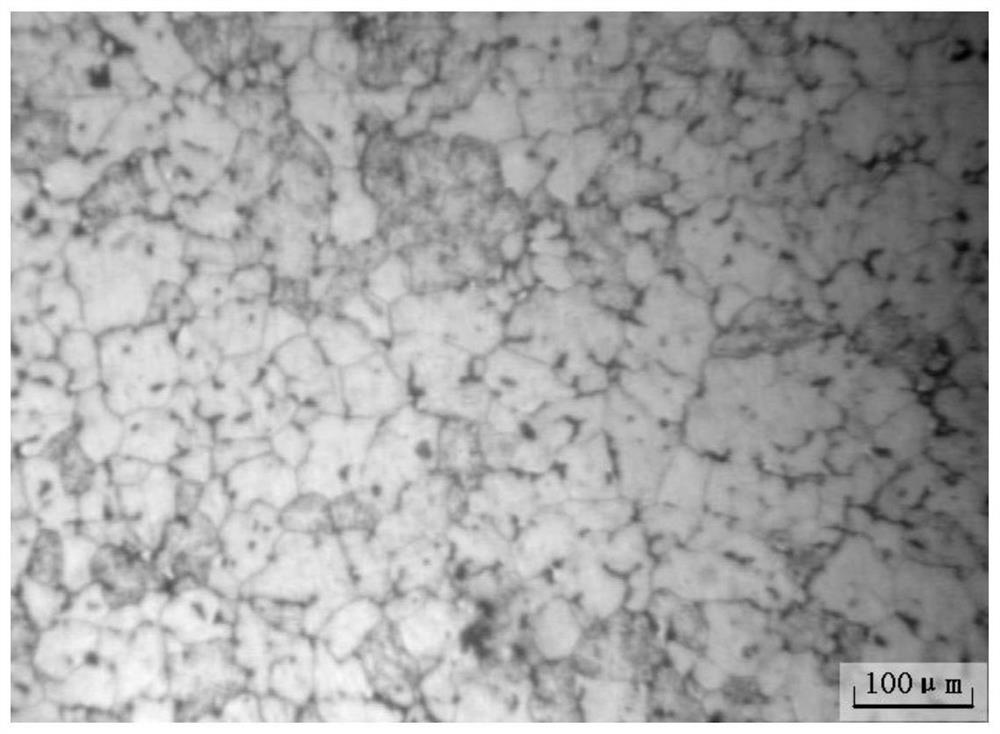

[0034] 2. Homogenization treatment: place the aluminum alloy ingot in a resistance heating furnace, keep it at 310°C for 15 hours, then raise the temperature to 560°C for 8 hours, and obtain the homoge...

Embodiment 3

[0038] In this example, a high-strength plastic aluminum alloy was prepared and tested according to the following steps:

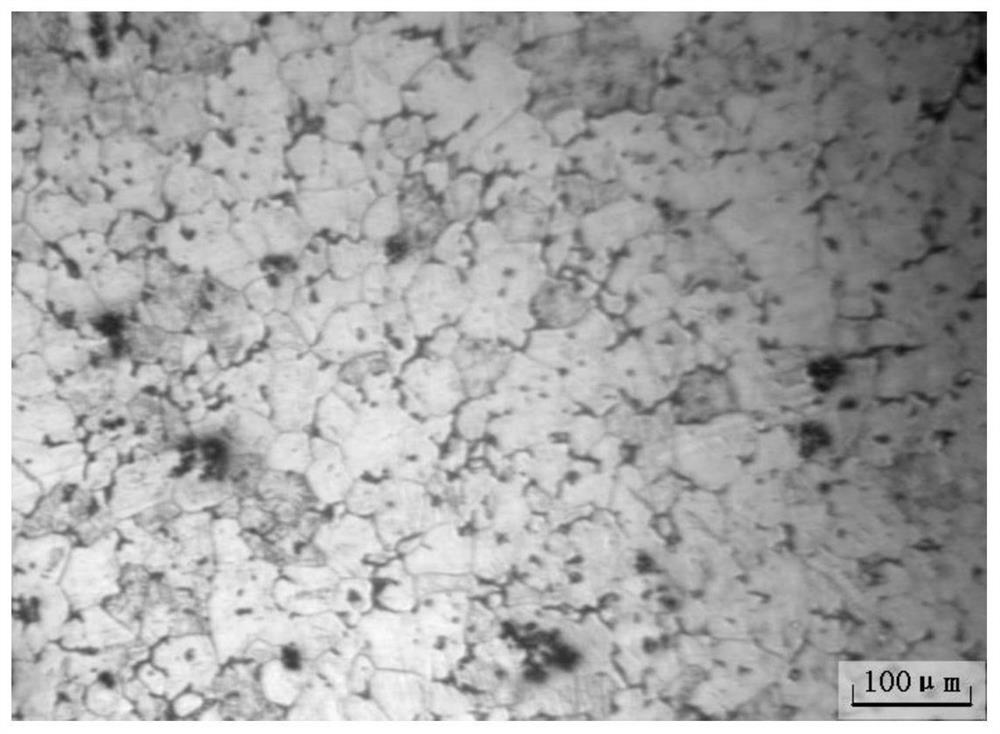

[0039] 1. Casting: According to the mass fraction of Cu in the aluminum alloy is 5.5%, the mass fraction of Mg is 0.6%, the mass fraction of Ag is 0.3%, the mass fraction of Mn is 0.3%, and the balance is Al. Weigh an appropriate amount of pure Al, pure Mg and Al-20wt% Cu, Al-20wt% Ag and Al-10wt% Mn master alloys; Al is completely melted, then add pure Mg, Al-Cu master alloy, Al-Ag master alloy, Al-Mn master alloy in turn, at a temperature of 760°C, mechanically stir for 15 minutes, then cool down to 700°C and stand for 15 minutes to obtain alloy melt body, cast into an iron mold at 300°C to obtain an aluminum alloy ingot, and air-cool to room temperature.

[0040] 2. Homogenization treatment: place the aluminum alloy ingot in a resistance heating furnace, keep it at 320°C for 12 hours, then raise the temperature to 580°C for 6 hours, and obtain the homo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com