Nanoparticle reinforced ZTC4 titanium alloy and preparation method thereof

A technology of ZTC4 and nano-particles, applied in the field of titanium alloys, has achieved great national economic significance and the effect of simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

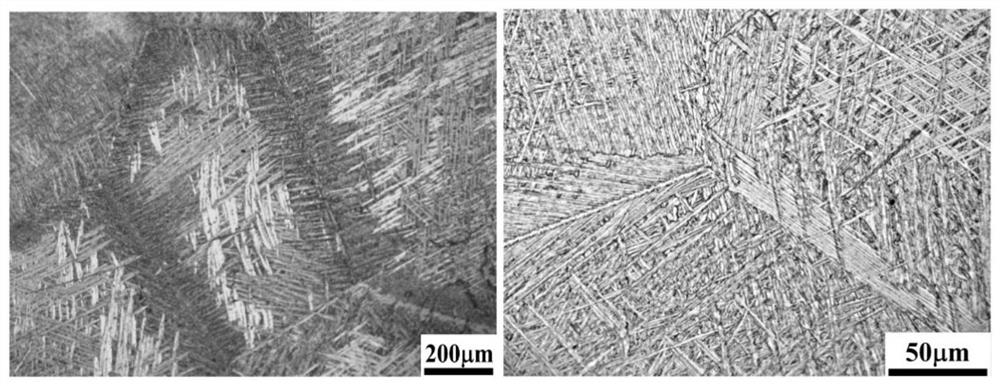

Image

Examples

Embodiment 1

[0031] This embodiment provides a kind of ZTC4 titanium alloy, and its preparation method comprises the following steps:

[0032] S1, carbon nanotubes and titanium powder with a particle size of 300 mesh are mixed according to a molar ratio of 1:1 to obtain a mixture; then, the mixture and a particle diameter of 500 mesh aluminum powder are placed in a mass ratio of 30:70 Mix in a ball mill at a speed of 50 rpm for 24 hours to obtain alloy powder.

[0033] S2. Put the above alloy powder in aluminum foil, press it into a cylindrical compact with a diameter of 25mm and a height of 35mm, then put the compact into a graphite mold, and place the graphite mold in a vacuum heating furnace at 30°C / min The heating rate is heated to 900°C for combustion synthesis, and after 10 minutes of heat preservation, it is cooled to room temperature with the furnace to obtain an aluminum-based master alloy containing nano-TiC particles, wherein the particle size of the nano-TiC particles is 60-120...

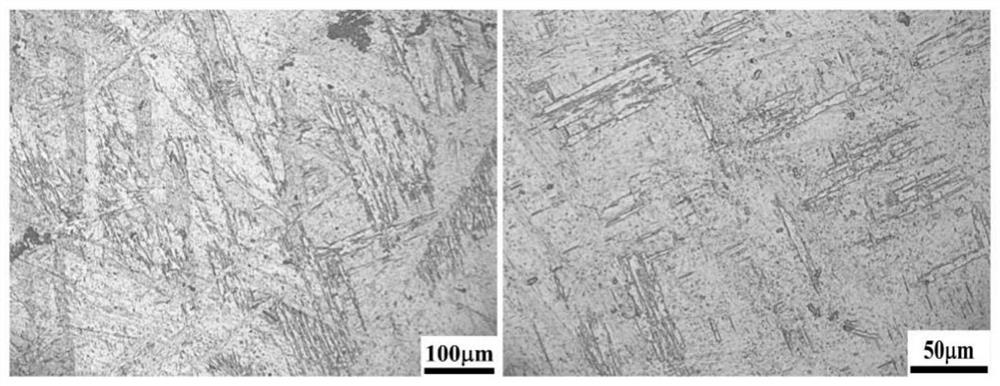

Embodiment 2

[0040] This embodiment provides a kind of ZTC4 titanium alloy, and its preparation method comprises the following steps:

[0041]S1, carbon nanotubes and titanium powder with a particle size of 300 mesh are mixed according to a molar ratio of 1:1 to obtain a mixture; then, the mixture and a particle diameter of 500 mesh aluminum powder are placed in a mass ratio of 30:70 Mix in a ball mill at a speed of 50 rpm for 24 hours to obtain alloy powder.

[0042] S2. Put the above alloy powder in aluminum foil, press it into a cylindrical compact with a diameter of 25mm and a height of 35mm, then put the compact into a graphite mold, and place the graphite mold in a vacuum heating furnace at 30°C / min The heating rate is heated to 900°C for combustion synthesis, and after 10 minutes of heat preservation, it is cooled to room temperature with the furnace to obtain an aluminum-based master alloy containing nano-TiC particles, wherein the particle size of the nano-TiC particles is 60-120n...

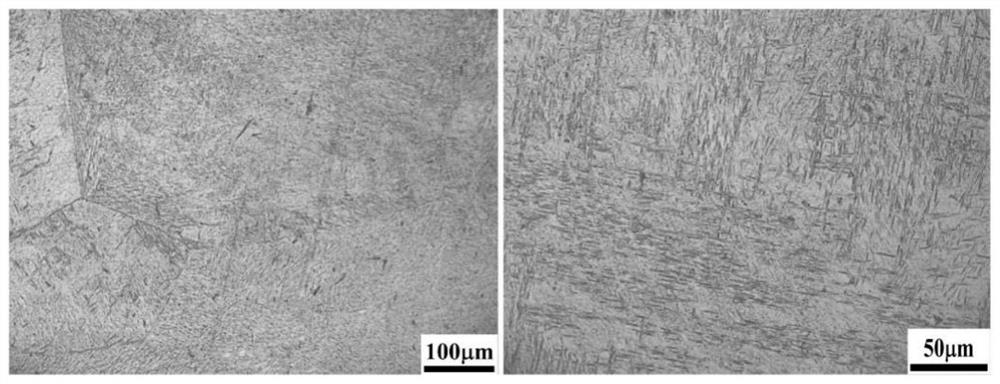

Embodiment 3

[0049] This embodiment provides a kind of ZTC4 titanium alloy, and its preparation method comprises the following steps:

[0050] S1, carbon nanotubes and titanium powder with a particle size of 300 mesh are mixed according to a molar ratio of 1:1 to obtain a mixture; then, the mixture and a particle diameter of 500 mesh aluminum powder are placed in a mass ratio of 30:70 Mix in a ball mill at a speed of 50 rpm for 24 hours to obtain alloy powder.

[0051] S2. Put the above alloy powder in aluminum foil, press it into a cylindrical compact with a diameter of 25mm and a height of 35mm, then put the compact into a graphite mold, and place the graphite mold in a vacuum heating furnace at 30°C / min The heating rate is heated to 900°C for combustion synthesis, and after 10 minutes of heat preservation, it is cooled to room temperature with the furnace to obtain an aluminum-based master alloy containing nano-TiC particles, wherein the particle size of the nano-TiC particles is 60-120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com