Preparation process of FeCrCoMnNi high-entropy alloy based composite material

A preparation process and composite material technology are applied in the field of preparation of high-entropy alloy-based composite materials to achieve the effects of high hardness, simple structure and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

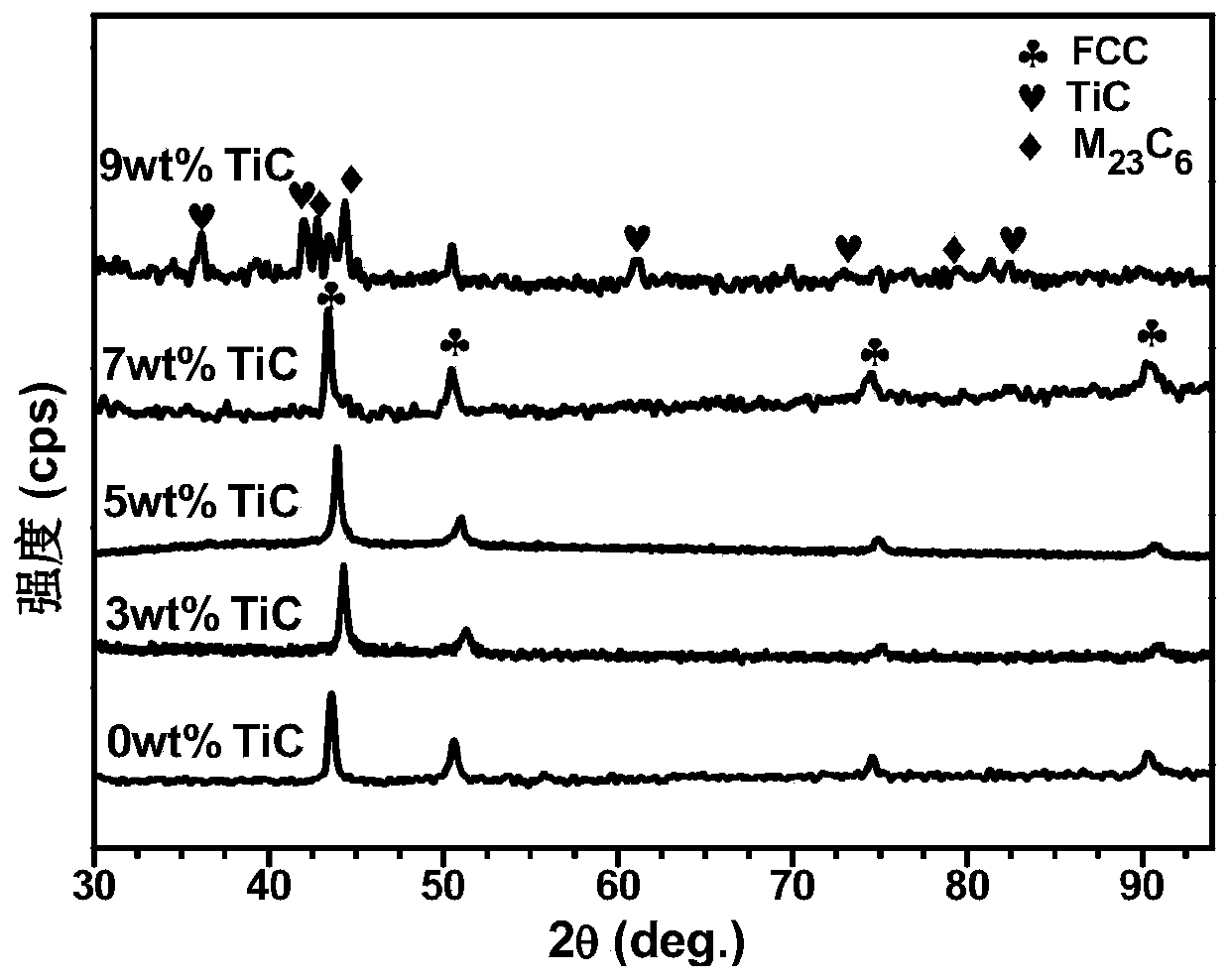

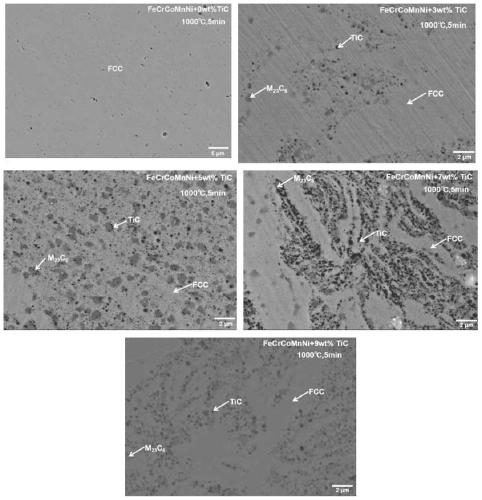

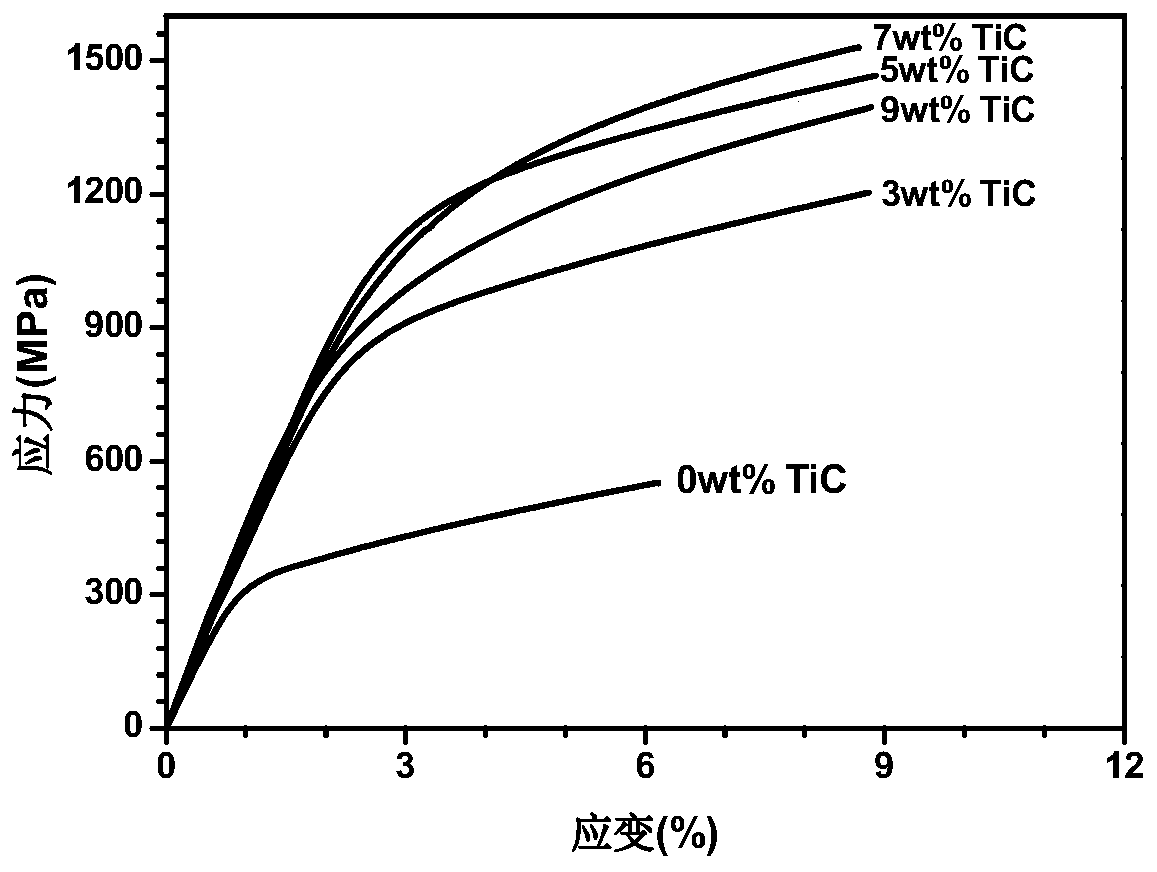

[0026] In this embodiment, the process of preparing FeCrCoMnNi high-entropy alloy-based composite material by spark plasma sintering is as follows:

[0027] 1. Preparation of mixed powder

[0028] Weigh 3wt% nano-TiC powder and 97wt% FeCrCoMnNi high-entropy alloy powder, pour the two powders into a stainless steel ball mill tank, add cemented carbide balls, the ball-to-material ratio is 10:1, the ball mill tank is first evacuated and then filled with argon Air, ball milled for 20 hours until completely mixed uniformly, the reaction sintered mixed powder is obtained;

[0029] 2. Assembly

[0030] Prepare a graphite mold with an inner diameter of 20mm, two matching graphite indenters, two graphite gaskets, and graphite paper; cut the graphite paper into two circular graphite papers with a diameter of 20mm and a rectangle that just covers the inner wall of the graphite mold Graphite paper: Paste the rectangular graphite paper on the inner wall of the graphite mold, and assemble...

experiment example 2

[0035] In this embodiment, the process of preparing FeCrCoMnNi high-entropy alloy-based composite material by spark plasma sintering is as follows:

[0036] 1. Preparation of mixed powder

[0037] Weigh 5wt% nano-TiC powder and 95wt% FeCrCoMnNi high-entropy alloy powder, pour the two powders into a stainless steel ball mill tank, add cemented carbide balls, the ball-to-material ratio is 10:1, the ball mill tank is first evacuated and then filled with argon Air, ball milled for 20 hours until completely mixed uniformly, the reaction sintered mixed powder is obtained;

[0038] 2. Assembly

[0039] Prepare a graphite mold with an inner diameter of 20mm, two matching graphite indenters, two graphite gaskets, and graphite paper; cut the graphite paper into two circular graphite papers with a diameter of 20mm and a rectangle that just covers the inner wall of the graphite mold Graphite paper: Paste the rectangular graphite paper on the inner wall of the graphite mold, and assemble i...

Embodiment 3

[0044] In this embodiment, the process of preparing FeCrCoMnNi high-entropy alloy-based composite material by spark plasma sintering is as follows:

[0045] 1. Preparation of mixed powder

[0046] Weigh 7wt% nano-TiC powder and 93wt% FeCrCoMnNi high-entropy alloy powder, pour the two powders into a stainless steel ball mill tank, add cemented carbide balls, the ball-to-material ratio is 10:1, the ball mill tank is first evacuated and then filled with argon Air, ball milled for 20 hours until completely mixed uniformly, the reaction sintered mixed powder is obtained;

[0047] 2. Assembly

[0048] Prepare a graphite mold with an inner diameter of 20mm, two matching graphite indenters, two graphite gaskets, and graphite paper; cut the graphite paper into two circular graphite papers with a diameter of 20mm and a rectangle that just covers the inner wall of the graphite mold Graphite paper: Paste the rectangular graphite paper on the inner wall of the graphite mold, and assemble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com