Optimization Method of Forging Process Parameters for Hydrogenated tc4 Titanium Alloy

An optimization method and technology of process parameters, applied in the direction of metal processing equipment, etc., can solve the problems of poor practicability and achieve the effect of improving the tensile strength at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1. Optimization of forging process parameters of TC4 titanium alloy with hydrogen content of 0.4 wt%.

[0026] (1) The supply state TC4 titanium alloy rod with a diameter of 18mm is machined to obtain a thermal simulation compression sample with a diameter of 8mm and a height of 12mm, and the TC4 titanium alloy sample is cleaned with absolute ethanol;

[0027] (2) Will The TC4 titanium alloy sample was placed in a hydrogen furnace, and the vacuum was evacuated to 1×10 -3 Pa, heat up to 750°C at a speed of about 5-15°C / min, hold for 8 minutes, fill the flow rate of hydrogen at 1L / min, hold for 2hrs, cool to room temperature at a speed of 5-10°C / min, and obtain hydrogen TC4 titanium alloy sample;

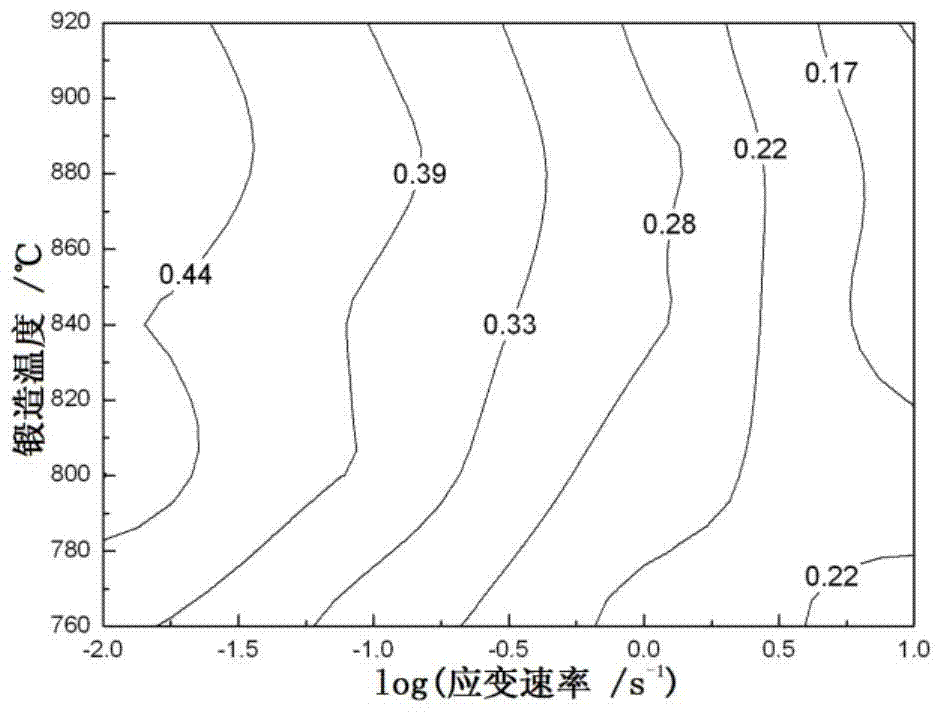

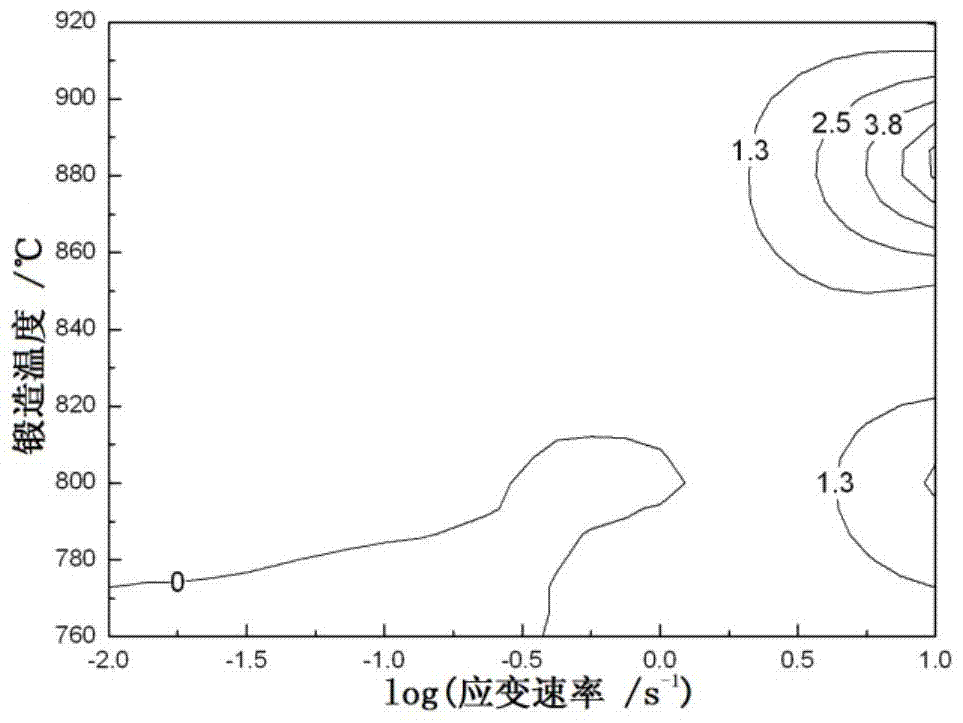

[0028] (3) Coat the FR5 glass lubricant on the surface of the hydrogenated TC4 titanium alloy thermal simulation compression sample, select natural hydrogen (supply state), hydrogen content 0.4wt%, deformation temperature 760°C, 800°C, 840°C, 880°C ℃, 920℃, strai...

Embodiment 2

[0042] Example 2: Optimization of forging process parameters of TC4 titanium alloy with 0.4 wt% hydrogen content.

[0043] The difference from step (6) in Example 1 is that the TC4 titanium alloy blade blank of the same size is placed in a forging die and heated to 820° C., and after 30 minutes of heat preservation, the blade is forged at a forging speed of 10 mm / min;

[0044] Table 2 Tensile strength of TC4 titanium alloy forged blade

[0045]

[0046] It can be seen from Table 2 that the room temperature tensile strength of TC4 titanium alloy forged blade with 0.4wt% hydrogen content is 1065MPa, which is 18.99% higher than the national standard (895MPa); TC4 titanium alloy forged blade with 0.4wt% hydrogen content The room temperature yield strength of the blade is 1000MPa, which is 21.21% higher than the national standard (825MPa); the 400°C tensile strength of the TC4 titanium alloy forged blade with 0.4wt% hydrogen content is 710MPa, which is 18.33% higher than the nat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com