Iron-based bulk metallic glass alloy with large supercooled liquid phase region

A technology of supercooled liquid phase region and bulk metal, applied in the field of new materials, can solve problems such as the use of difficult-to-metal glass alloys and low stability of supercooled liquids, and achieve the effects of low cost, low production cost and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

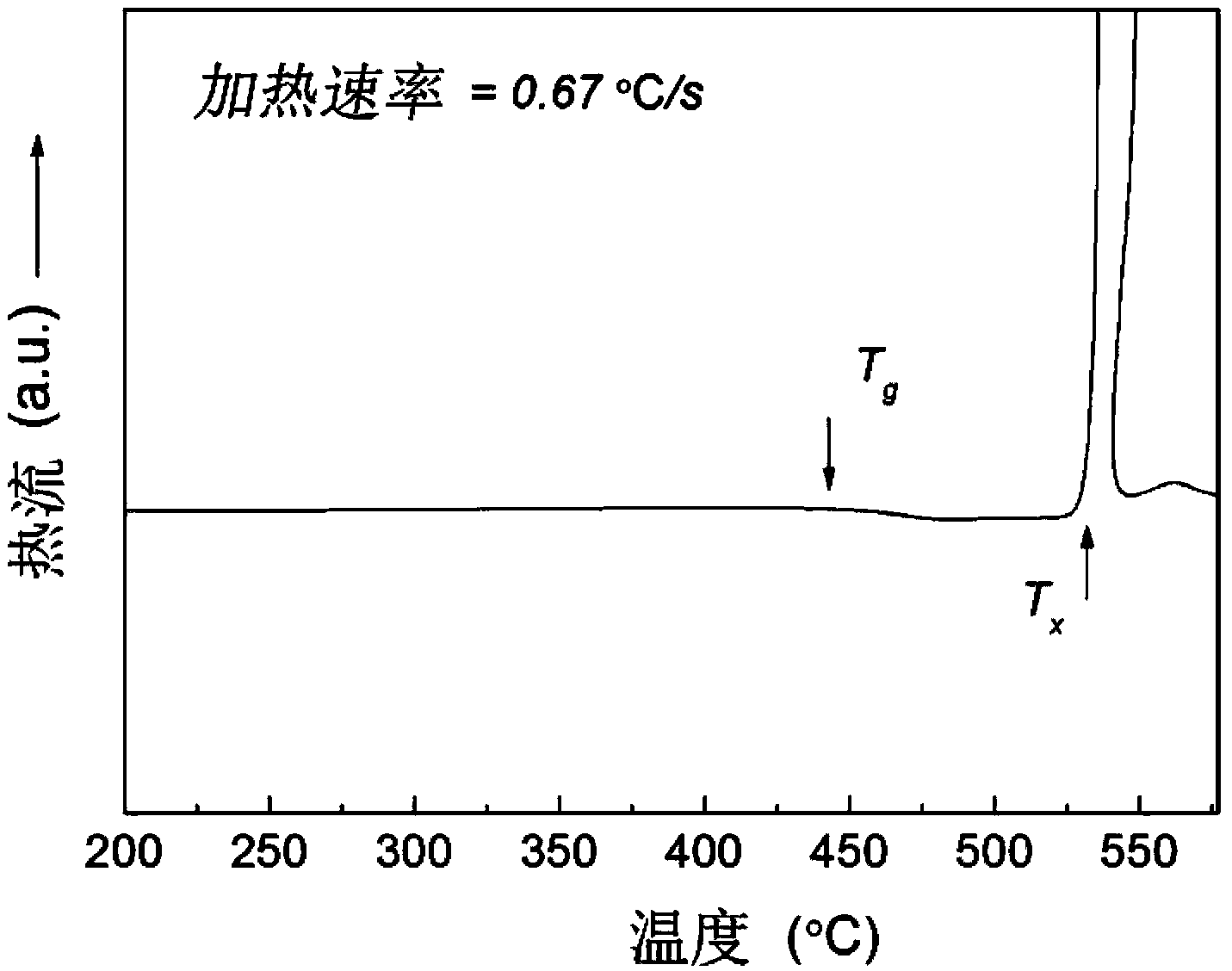

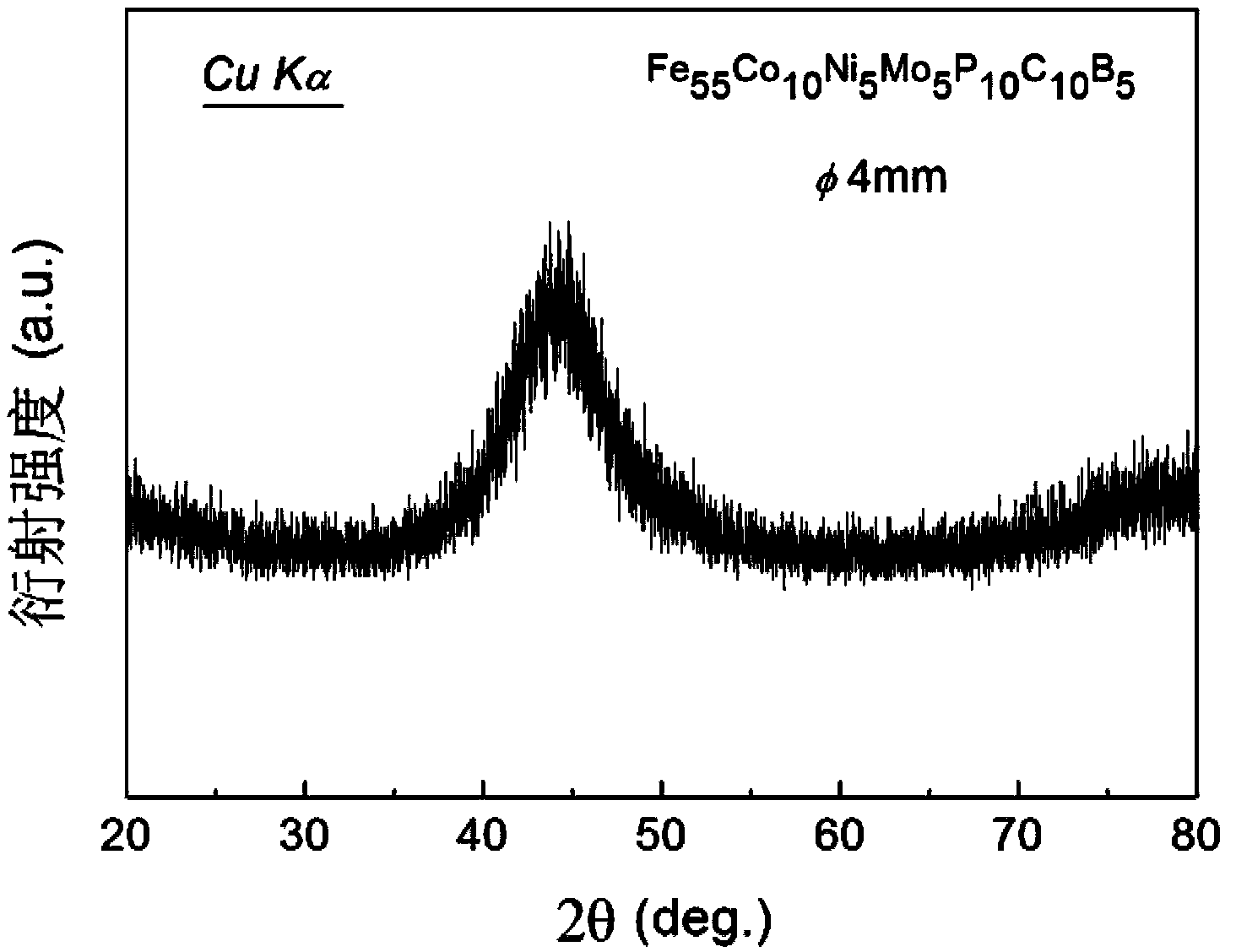

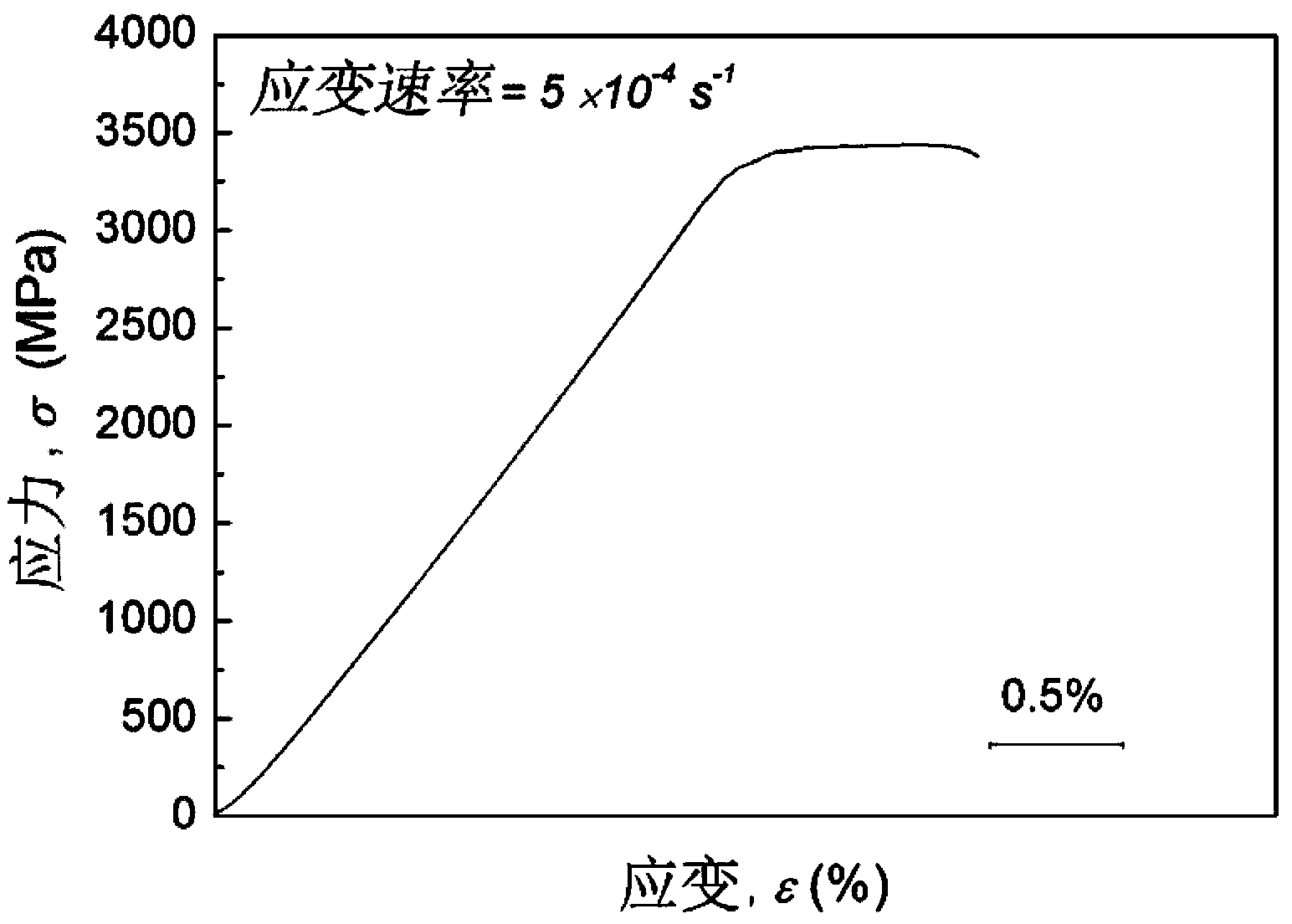

[0036] Fe 55 co 10 Ni 5 Mo 5 P 10 C 10 B 5 Preparation, testing and superplastic processing of metallic glass alloys.

[0037] (1) High-purity elements are used for compounding according to the chemical composition ratio of the alloy. Phosphorus is added through the iron-phosphorus alloy. The purity of the elements in terms of mass percentage is: iron: 99.9%, cobalt: 99.9%, nickel: 99.9%, molybdenum : 99.9%, carbon: 99.999%, boron: 99.5%, iron phosphorus: 99.9%.

[0038] (2) Put the proportioned raw materials into the crucible of the induction melting furnace, and evacuate to 2×10 -3 Pa, filled with argon, in the argon atmosphere, using high-frequency induction melting 4 times, to obtain a master alloy ingot with uniform composition.

[0039] (3) Break the master alloy ingot and put it into a quartz tube with a small hole at the bottom. After vacuuming, fill it with argon gas. In the argon atmosphere, first heat the master alloy to a molten state by high-frequency ind...

Embodiment 2

[0048] Fe 55 Ni 15 Mo 5 P 10 C 10 B 5 Preparation, testing and superplastic processing of metallic glass alloys. Step is with embodiment 1, and concrete data is listed in attached table.

Embodiment 3

[0050] Fe 65 Ni 5 Mo 5 P 10 C 10 B 5 Preparation, testing and superplastic processing of metallic glass alloys. Step is with embodiment 1, and concrete data is listed in attached table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com