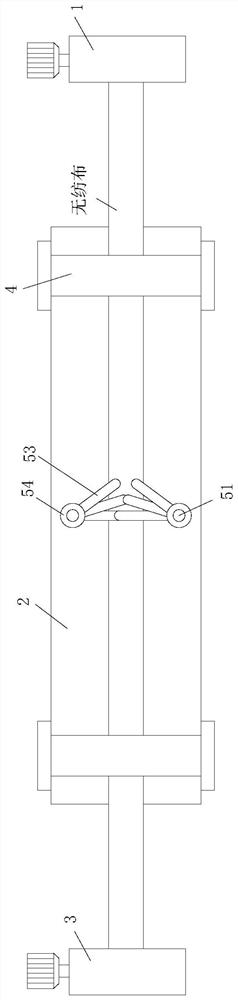

Non-woven fabric pleating device and mask production line

A non-woven fabric and pleating technology, which is applied in the fields of non-woven fabric pleating devices and mask production lines, can solve the problems of low wrinkling efficiency and lack of support for non-woven fabrics, and achieve improved application value, strong structural strength, and cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

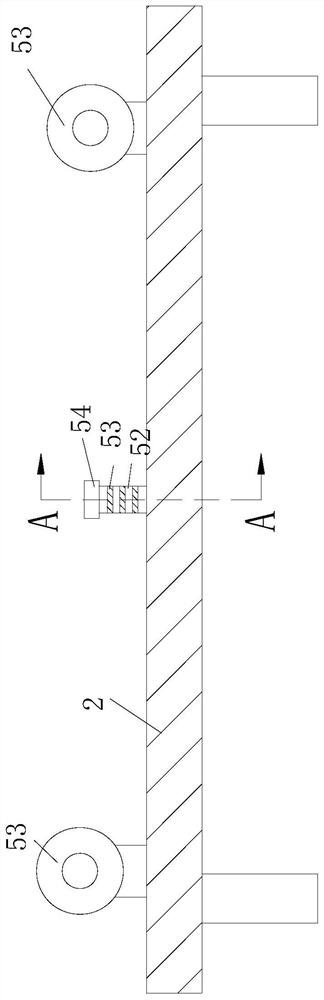

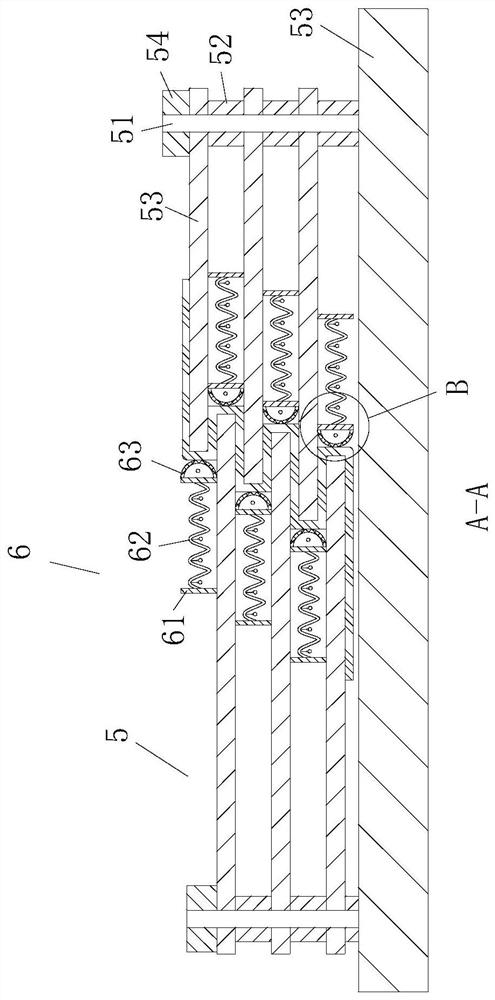

[0030]As a specific embodiment of the present invention, the wrinkle plate 53 is provided with a guide plate 7 on one side of the roller 1, the guide plate 7 tilt, the width of the guide plate 7 adjacent to the wrinkle plate 53 And gradually increase. The present invention can increase the contact area of the wrinkle plate 53 and the nonwoven fabric in the right side of the wrinkle plate 53, and can effectively guide the nonwoven fabric in the movement, thereby It is made faster, and thereby increasing the application value of the present invention, and the guide plate 7 of the present invention can be inclined, and the non-woven fabric to the wrinkle plate 53 can be effectively transitioned, and the guide plate 7 The width gradually increases with the wrinkle plate 53, which can cause strength strength of the guide plate 7 and not easily break from the wrinkle plate 53.

[0031] As a specific embodiment of the present invention, the guide plate 7 is fixedly coupled with a swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com