Splitting circular knife and splitting machine

A technology of slitting machine and circular knife, applied in metal processing and other directions, can solve the problems of generating burrs, increasing the difficulty and loss of base paper processing, and achieving the effect of uniform force, easy subsequent processing, and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

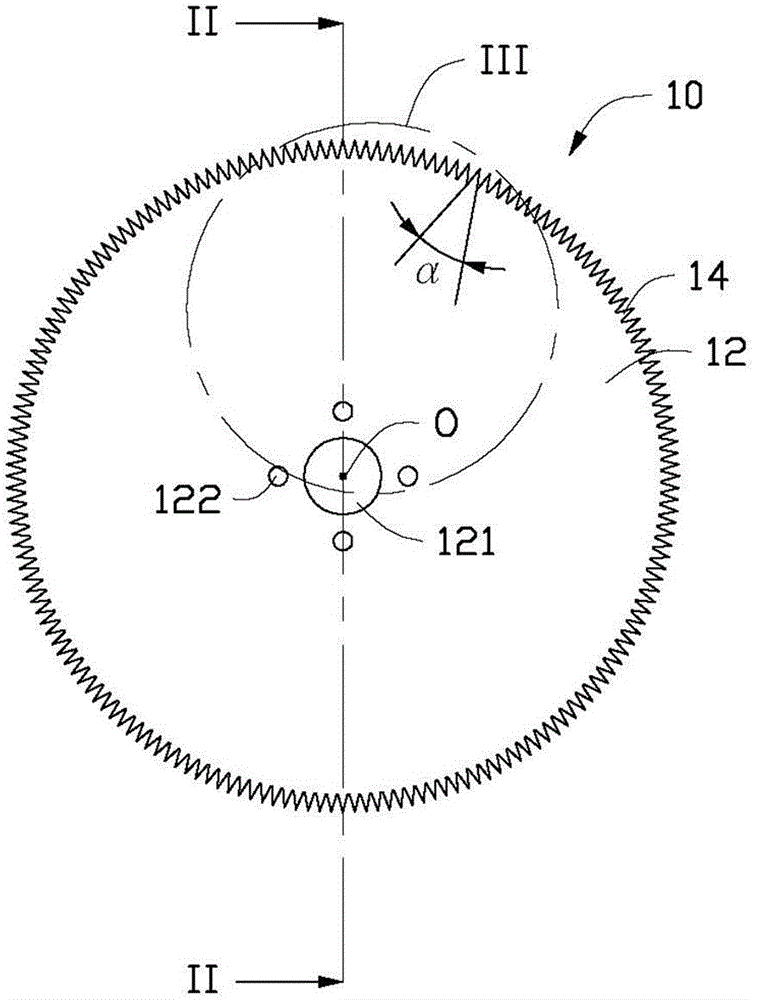

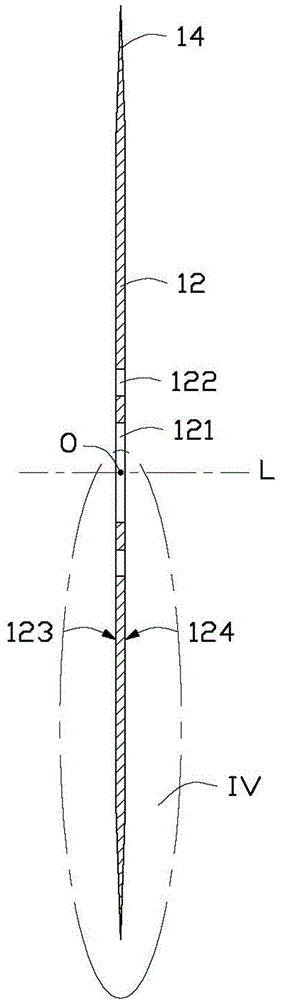

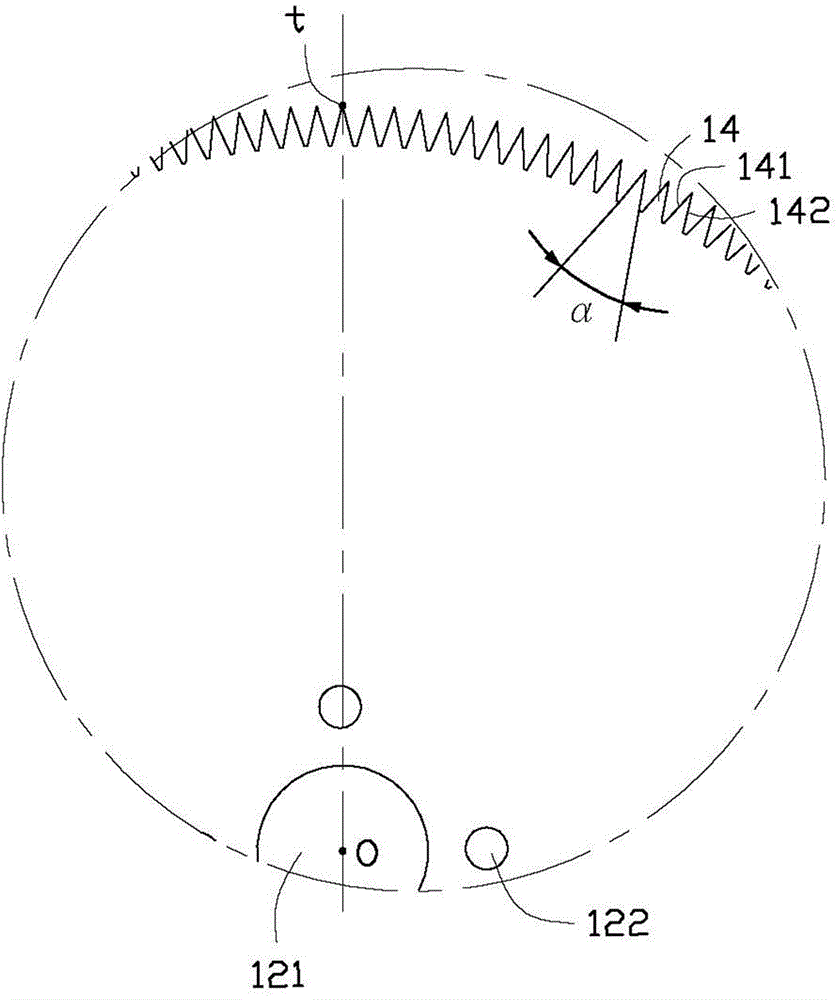

[0019] Such as figure 1 and figure 2 As shown, a circular cutting knife 10 provided by the present invention includes a circular knife body 12 and knife teeth 14 distributed on the periphery of the knife body 12 .

[0020] The cutter body 12 has two opposing sides 123 , 124 . The side surfaces 123 , 124 are flat and parallel to each other, and the distance between the two side surfaces 123 , 124 is the thickness of the cutter body 12 . A shaft hole 121 is opened at the central axis L of the cutter body 12 . The size of the shaft hole 121 can be determined according to the dimensions of the components to be installed on the cutter body 12 . A plurality of fixing holes 122 are defined around the shaft hole 121 on the cutter body 12 . The fixing holes 122 are used for passing the fixing parts to fix the circular cutting knife 10 on related components.

[0021] Cutter tooth 14 is a straight tooth shape. The cutter teeth 14 are evenly distributed on the periphery of the cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com