Decorative ribbon cutting machine

A cutting machine and decorative tape technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of low work efficiency and burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

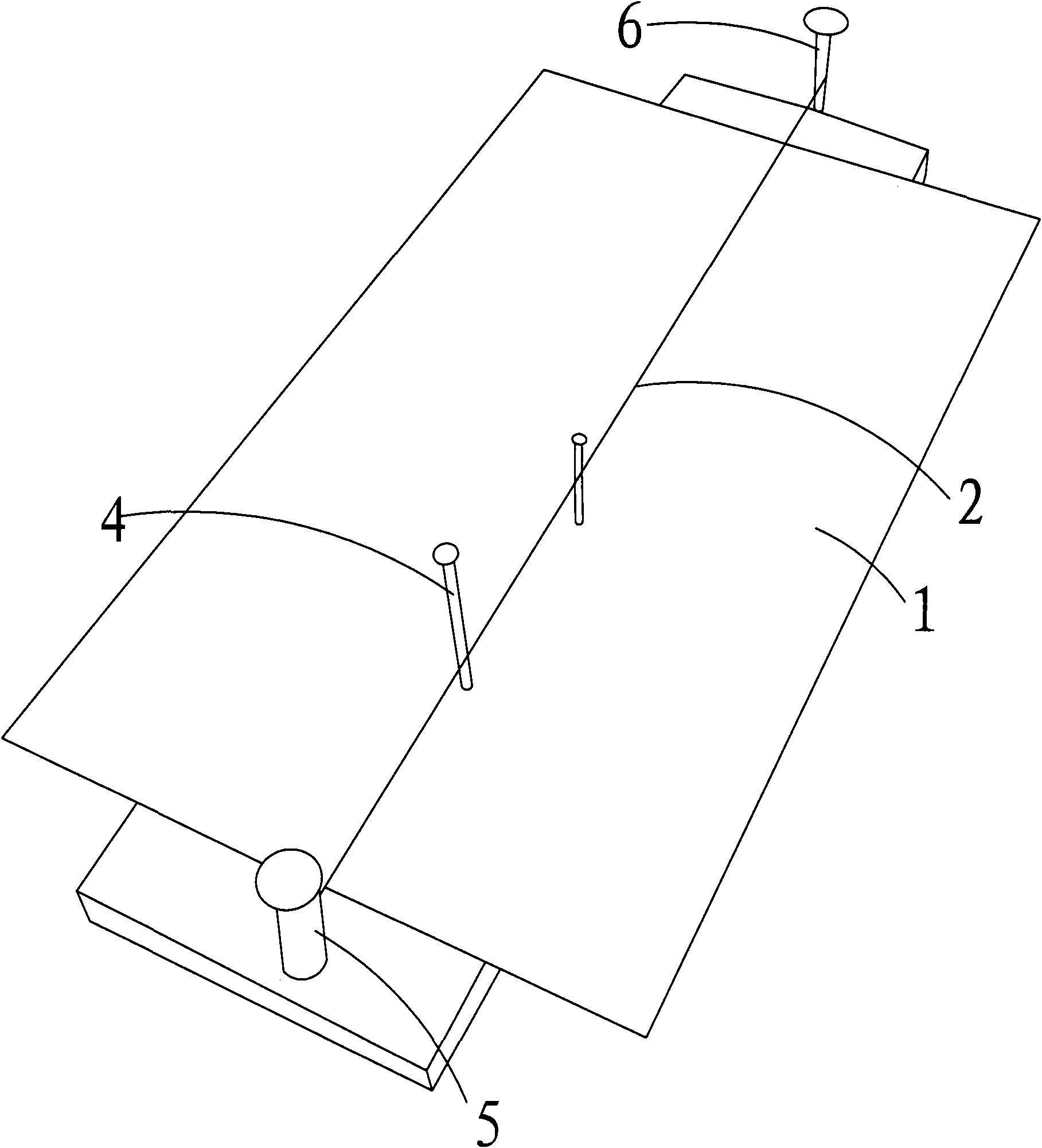

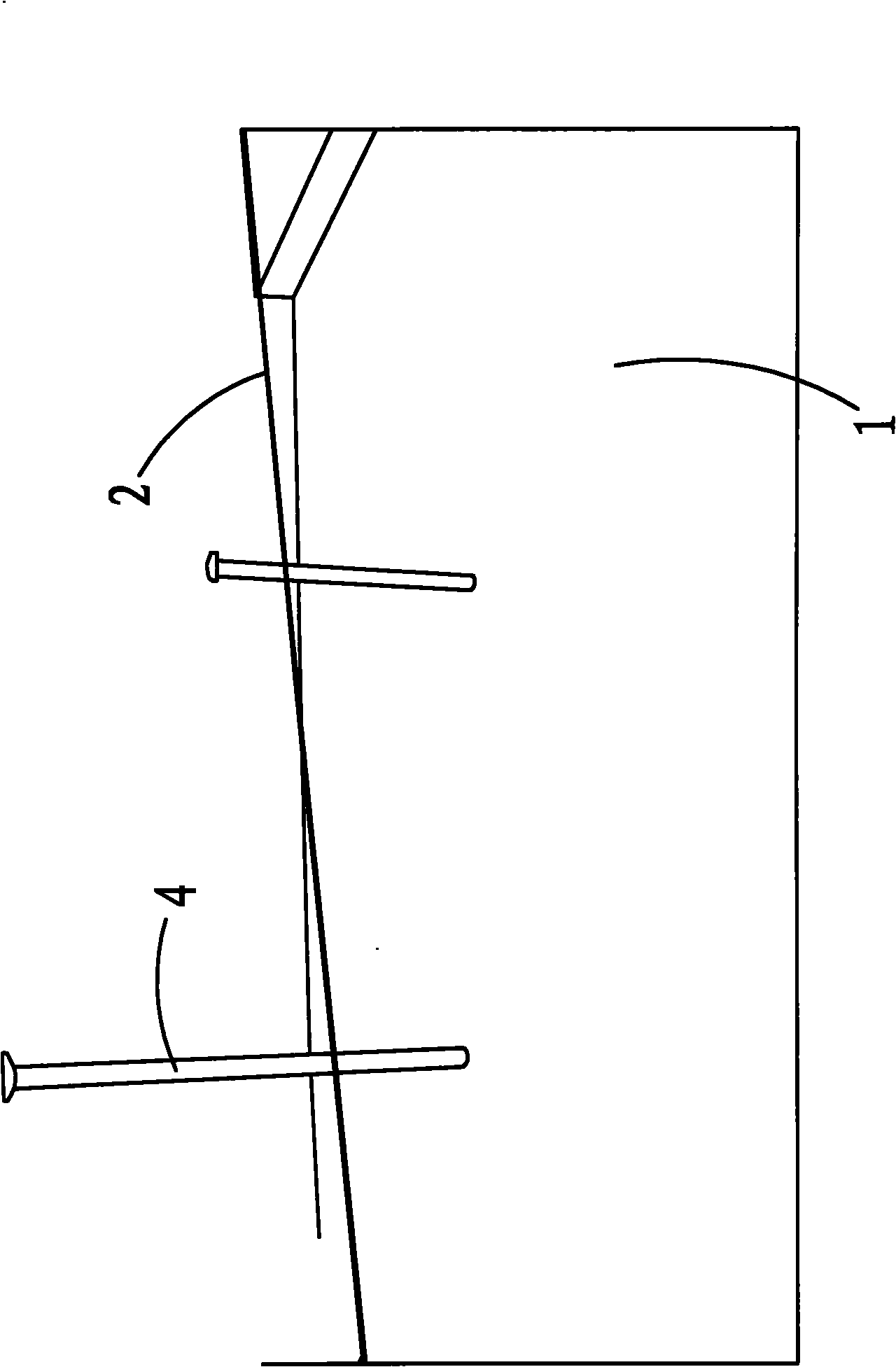

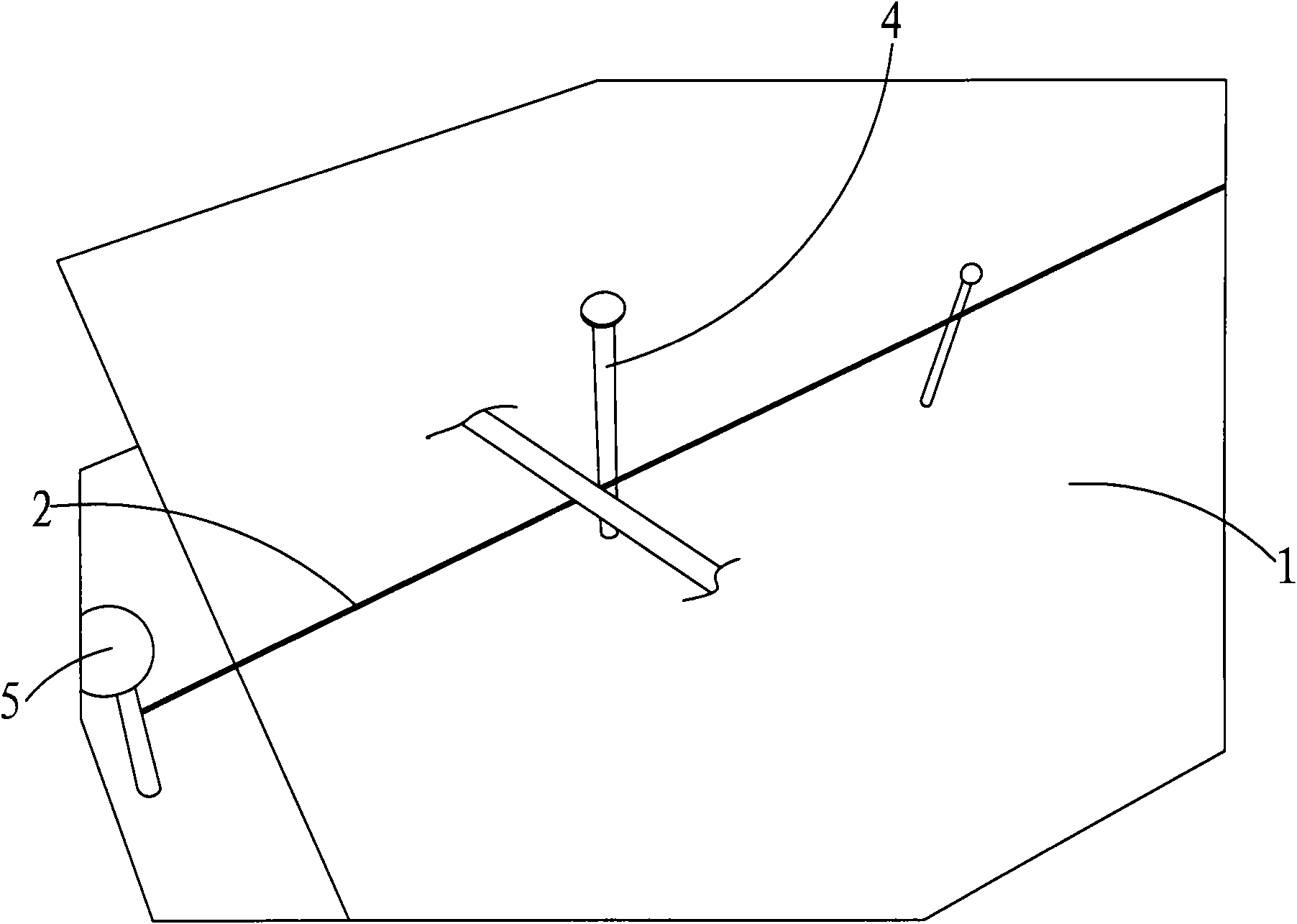

[0014] as attached figure 1 - attached Figure 4 As shown, a decorative tape cutting machine includes a frame 1 , a heating wire 2 arranged on the frame 1 , and a power supply 3 electrically connected to the heating wire 2 . After the power supply 3 is connected, the heating wire 2 generates heat, and the decorative tape can be cut off only by being close to the heating wire 2 .

[0015] as attached figure 1 - attached image 3 As shown, the frame 1 is also provided with positioning columns 4 . It is convenient to cut the decorative belt into a certain size, and the operation is convenient.

[0016] as attached figure 1 , attached image 3 As shown, the frame 1 is fixed with a first mounting column 5 and a second mounting column 6, and the heating wire 2 is connected between the first mounting column 5 and the second mounting column 6 Between, the positioning column 4 is located between the first installation column 5 and the second installation column 6 .

[0017] As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com