Packaging film without fuzzing in bag making and manufacturing method thereof

A technology for packaging film and base film, applied in the field of packaging film, can solve the problems of easy burrs, fluff, foreign matter mixing, etc., and achieve the effect of improving burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

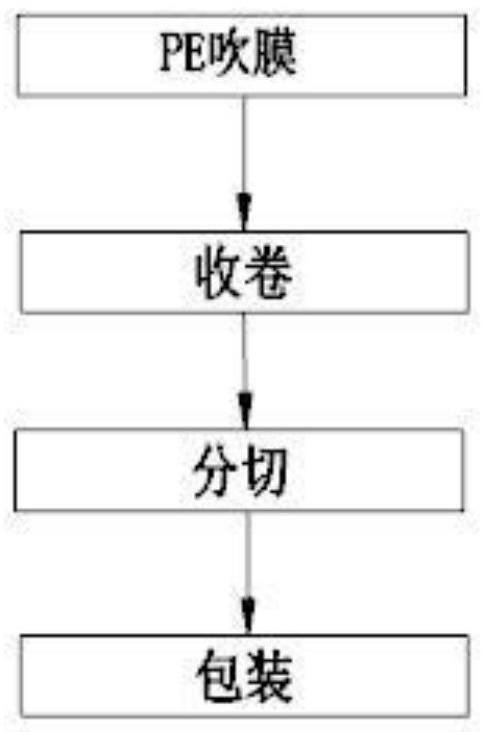

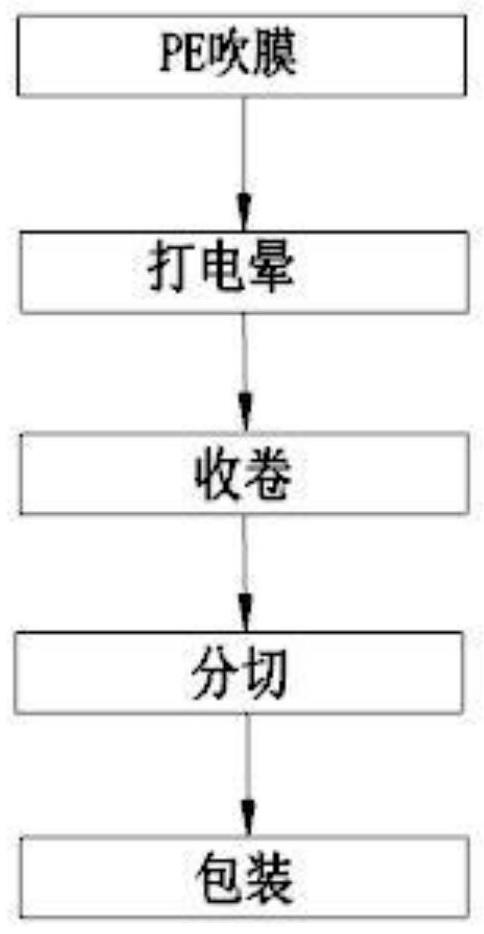

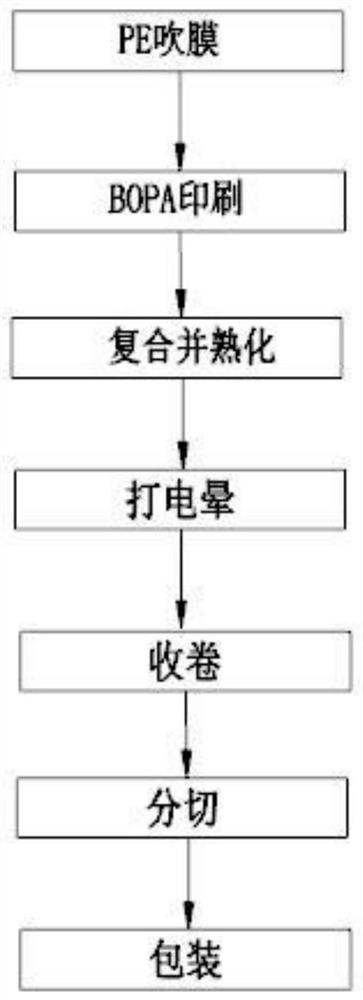

Method used

Image

Examples

Embodiment 1

[0095] A lint-free packaging film for bag making, comprising a three-layer co-extrusion blown film machine blown into a film to form a three-layer co-extrusion layer, wherein the three-layer co-extrusion layer is composed of an inner layer base film, a middle layer base film and an outer layer base film. composition, the inner base film is a heat-sealing layer, and the outer base film is a corona-treated layer or a composite layer;

[0096] The thickness of the inner layer base film is 42um, and the components of the inner layer base film are as follows by mass percentage:

[0097] LLDPE: 40%,

[0098] LDPE: 51%,

[0099] MLLDPE: 6.1%,

[0100] Opening slip agent: 2.5%,

[0101] PPA: 0.4%;

[0102] The components of the middle layer base film are as follows by mass percentage:

[0103] LLDPE: 49%,

[0104] LDPE: 50.8%,

[0105] PPA: 0.2%;

[0106] The components of the outer layer base film by mass percentage are as follows:

[0107] LLDPE: 49.6%,

[0108] LDPE: 50%,...

Embodiment 2

[0124] A lint-free packaging film for bag making, comprising a three-layer co-extrusion blown film machine blown into a film to form a three-layer co-extrusion layer, wherein the three-layer co-extrusion layer is composed of an inner layer base film, a middle layer base film and an outer layer base film. composition, the inner base film is a heat-sealing layer, and the outer base film is a corona-treated layer or a composite layer;

[0125] The thickness of the inner layer base film is 50um, and the components of the inner layer base film are as follows by mass percentage:

[0126] LLDPE: 43%,

[0127] LDPE: 50%,

[0128] MLLDPE: 5%,

[0129] Opening Slip: 1.7%,

[0130] PPA: 0.3%;

[0131] The components of the middle layer base film are as follows by mass percentage:

[0132] LLDPE: 49.5%,

[0133] LDPE: 50.2%,

[0134] PPA: 0.3%;

[0135] The components of the outer layer base film by mass percentage are as follows:

[0136] LLDPE: 49.8%,

[0137] LDPE: 50%,

[0...

Embodiment 3

[0152] A lint-free packaging film for bag making, comprising a three-layer co-extrusion blown film machine blown into a film to form a three-layer co-extrusion layer, wherein the three-layer co-extrusion layer is composed of an inner layer base film, a middle layer base film and an outer layer base film. composition, the inner base film is a heat-sealing layer, and the outer base film is a corona-treated layer or a composite layer;

[0153] The thickness of the inner layer base film is 75um, and the components of the inner layer base film are as follows by mass percentage:

[0154] LLDPE: 45%,

[0155] LDPE: 47.5%,

[0156] MLLDPE: 6%,

[0157] Opening Slip: 1.2%,

[0158] PPA: 0.3%;

[0159] The components of the middle layer base film are as follows by mass percentage:

[0160] LLDPE: 49.5%,

[0161] LDPE: 50.3%,

[0162] PPA: 0.2%;

[0163] The components of the outer layer base film by mass percentage are as follows:

[0164] LLDPE: 49.2%,

[0165] LDPE: 50.4%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com