Transfer type perspective safe-guarding and anti-counterfeiting film and method for protecting certificate security

A security protection, security and anti-counterfeiting technology, applied in stamps, instruments, identification devices, etc., can solve the problems of imitation and difficult identification, and achieve the effects of improving service life, good softness, and high scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

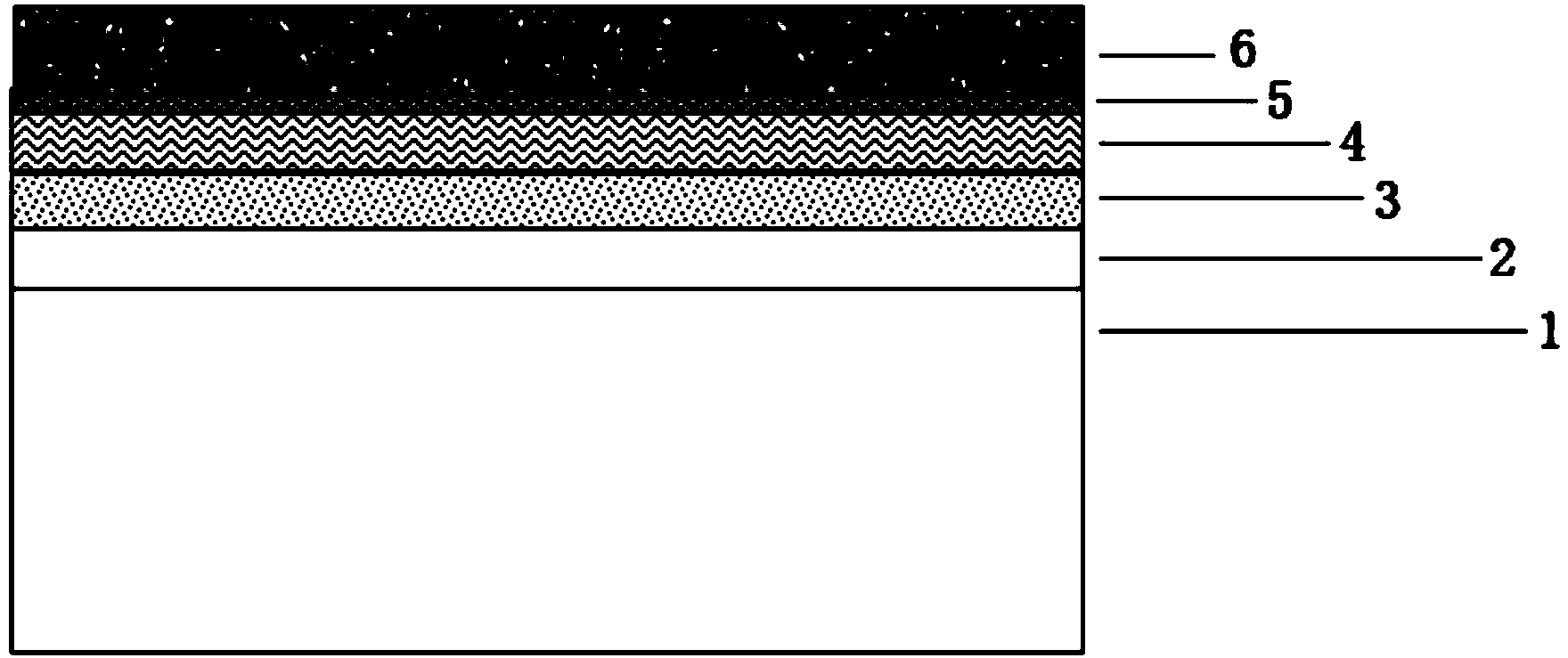

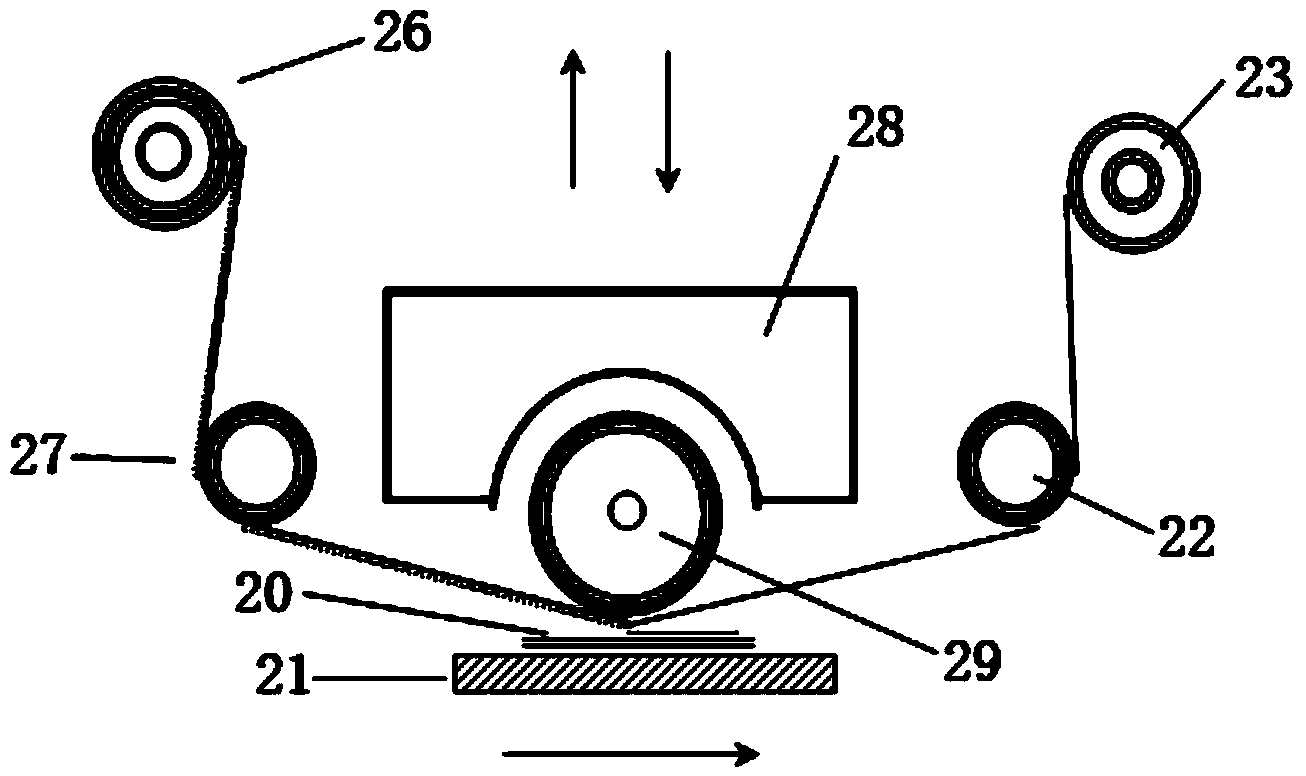

[0040] A security anti-counterfeiting film for transfer type documents such as figure 1 As shown, the base layer 1 of 20 μm optical grade PET base film is used, and the separation layer 2 is coated on the surface layer by the same coating machine, and the modified two-component epoxy resin is used as the protective layer 3 coating, and the reaction is cured. Then coat the information layer 4, and use commercial molding equipment to copy the optical structure on the motherboard to the surface of the information layer, and perform corona treatment on the surface of the information layer. Use a continuous vacuum coating machine to perform zinc sulfide electroplating on the molded information layer to embed the dielectric film layer 5, and finally use a coating machine to apply high-temperature hot-melt adhesive to obtain an adhesive layer 6, and carry out the above-mentioned semi-finished coil material suitable for certificate transfer Slitting of equipment specifications and len...

Embodiment 2

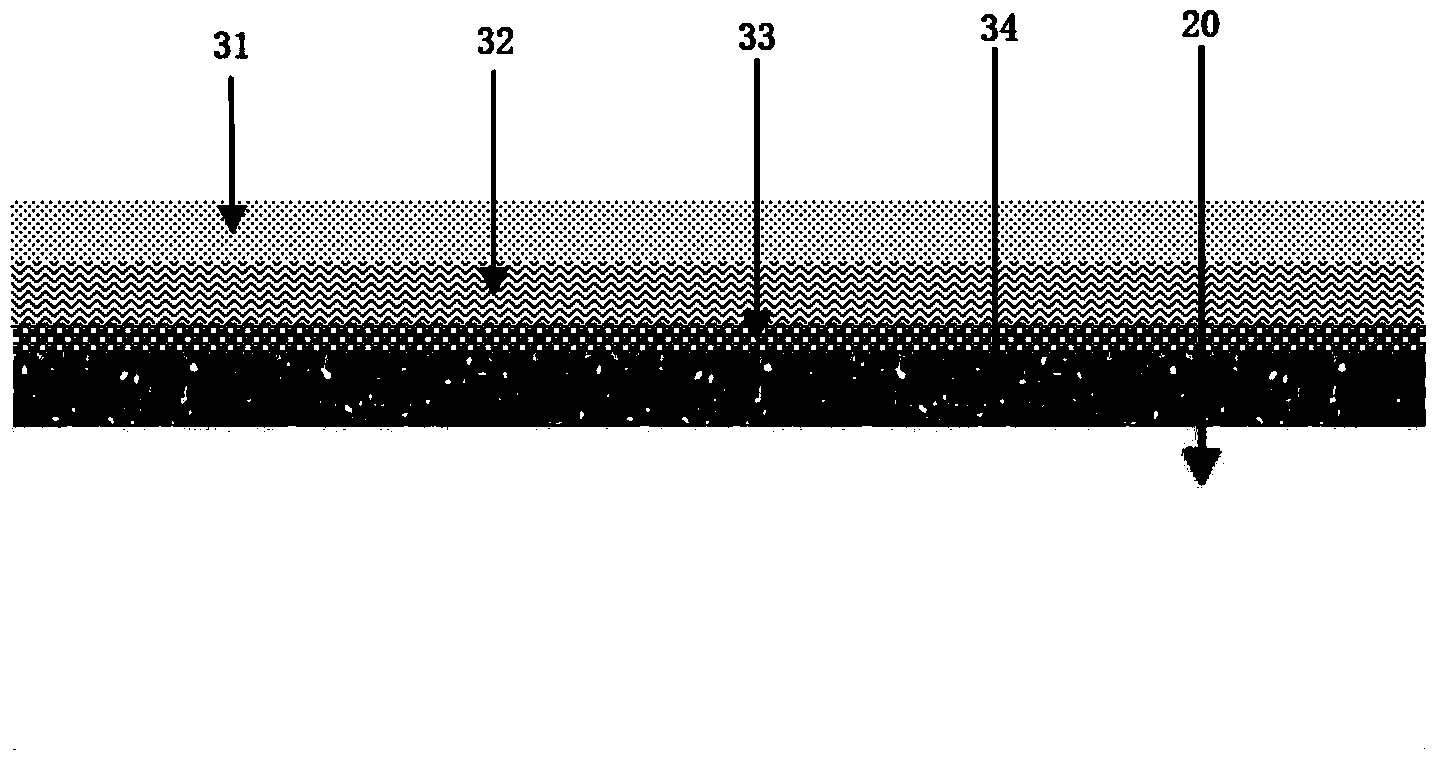

[0042] The second transfer-type document security anti-counterfeiting film such as figure 1, using 20μm optical grade PET base film base layer 1, coating the separation layer 2 on the surface layer with a coating machine, using modified two-component epoxy resin as the protective layer 3 coating, and coating after reaction curing UV information layer 4, copying and curing the optical structure on the motherboard on the surface of the UV layer; corona treatment is carried out on the surface of the information layer, and the information image obtained by copying is tracked and positioned with a digital printing machine to print the cursor code, as shown in Figure 4 (a ); Use a continuous vacuum coating machine to carry out zinc sulfide electroplating and landfill on the information layer after molding. figure 1 , and finally use a coating machine for high-temperature hot-melt adhesive coating to obtain a coating see figure 1 , cut the above-mentioned semi-finished coil material...

Embodiment 3

[0044] The third type of security anti-counterfeiting film for transfer documents figure 1 , use 20μm optical grade PET base film base layer 1, and use a coating machine to coat the separation layer 2 on the surface layer; use modified two-component epoxy resin as the protective layer coating 3; after reaction and curing, coat Cloth the information layer 4; adopt commercial positioning molding and printing integrated equipment, first input the film material coated with the information layer into the molding unit, copy the optical structure on the motherboard to the surface of the information layer by hot pressing, and then directly enter the printing unit , register the printed ink tracking line and position the cursor through the molded information, see Figure 4(a); corona treatment is performed on the surface of the information layer; zinc sulfide electroplating is used to bury the molded information layer with a continuous vacuum coating machine, see Figure 4(a). figure 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com