Protective device for karst cave and waterway drilling method using the protective device

A protection device and karst cave technology, which is applied in the field of exploration engineering, can solve the problems of taking a long time, cannot be taken out, and buried in the stratum, and achieves the effect of simplified overall structure, strong practicability, and stable burial.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

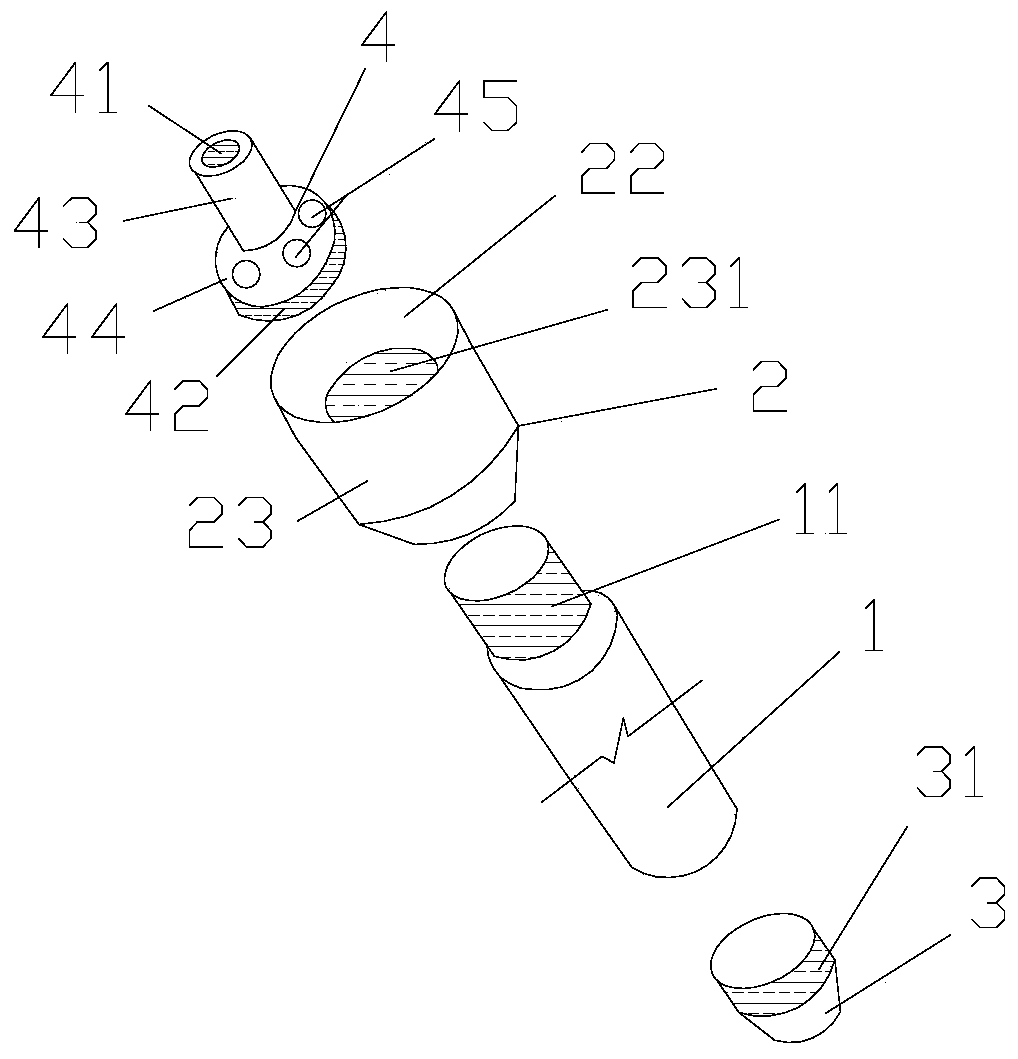

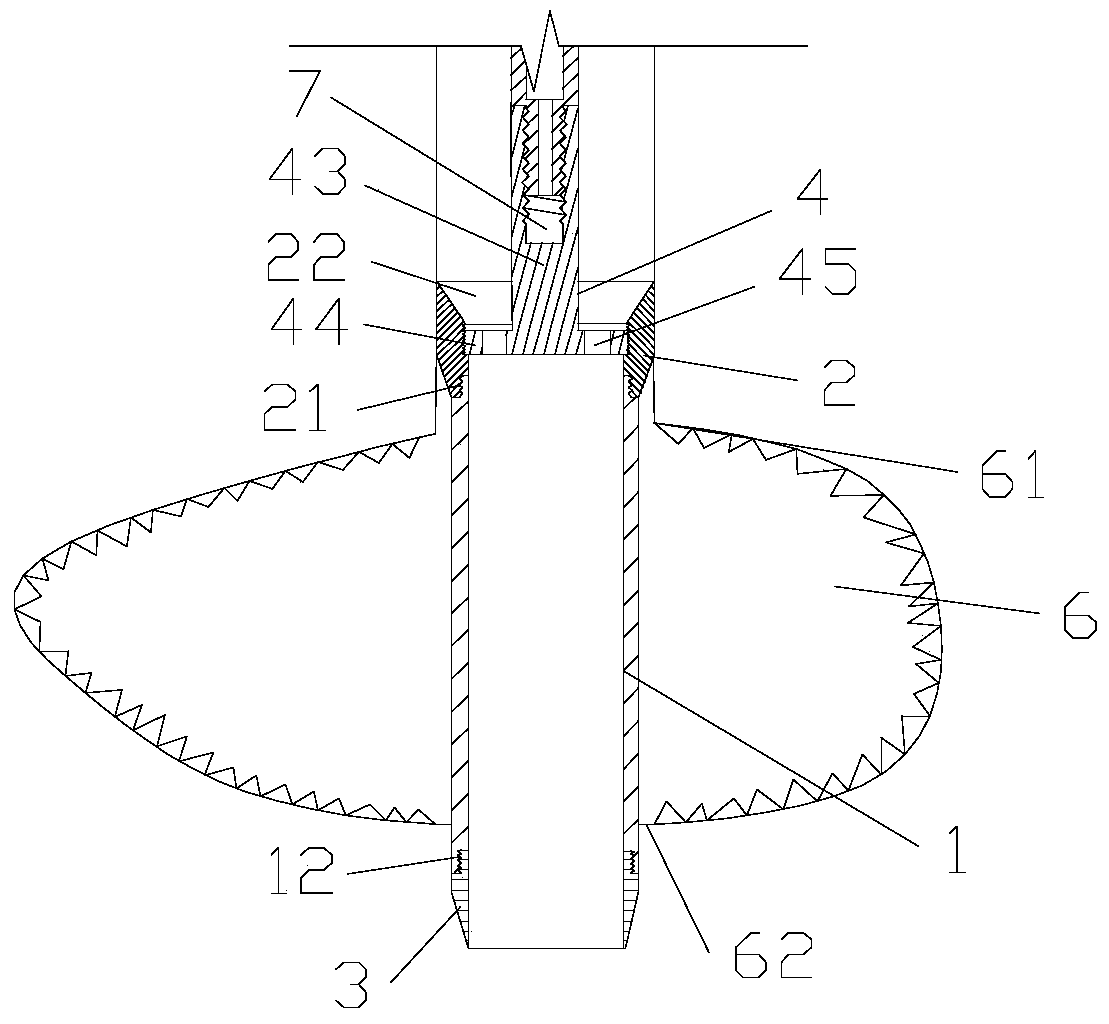

[0041] see figure 1 as well as figure 2 , a protective device for a cave, comprising a group of protective single pieces, the protective single piece includes a casing 1, a casing joint 2 arranged at the upper end of the casing 1 and connected to a drill pipe 7 through a casing adapter 4, and The sleeve blade 3 provided at the lower end of the sleeve 1, the sleeve joint 2 and the sleeve blade 3 both have a first through hole having the same inner diameter as the sleeve 1 and concentric with the central axis.

[0042] The outer wall of the upper end of the casing 1 is provided with a first external thread 11, and the inner wall of the lower end is provided with a first internal thread 12; along the vertical direction, the length of the casing 1 is 8%-20% larger than the height of the cave. %.

[0043] The outer wall of the upper end of the casing blade foot 3 is provided with a second external thread 31 that matches the first internal thread 12, and the outer wall of the low...

Embodiment 2

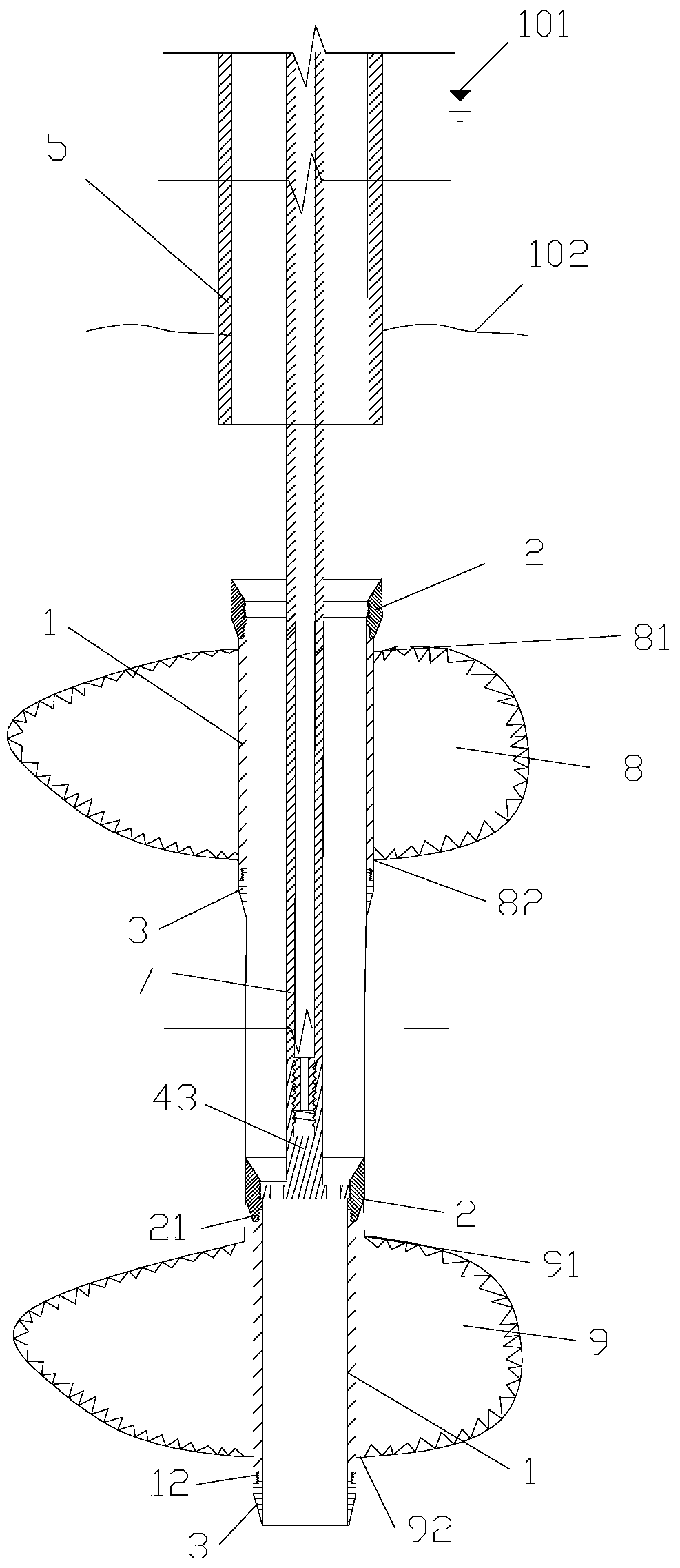

[0059] A protective device for karst caves, comprising a first set of protective single pieces and a second set of protective single pieces one size smaller than the first set of protective single pieces, the second set of protective single pieces can be obtained from the first set of protective single pieces completely through. The structure of the first group of protective individual pieces and the second group of protective individual pieces is the same as that of the protective individual piece in Embodiment 1.

[0060] The above-mentioned protective device for karst caves is applied to the water drilling process of the channel with two layers of karst caves. For the schematic diagram of the protective device for karst caves in this embodiment used for drilling, see image 3 .

[0061] The specific construction method includes the following steps:

[0062] Step 1: according to the conventional water drilling method, embed the large-diameter perforated pipe casing 5 from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com