A kind of polyethylene masterbatch composite auxiliary agent and preparation method thereof

A technology of compounding additives and polyethylene, applied in the field of plastic additives, can solve the problems that affect the optical properties and mechanical properties of film products, and can not effectively overcome the uneven dispersion of additives and anti-blocking agents at the same time, so as to eliminate fire hazards, Filling the mold is easy to reduce and improve the effect of hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

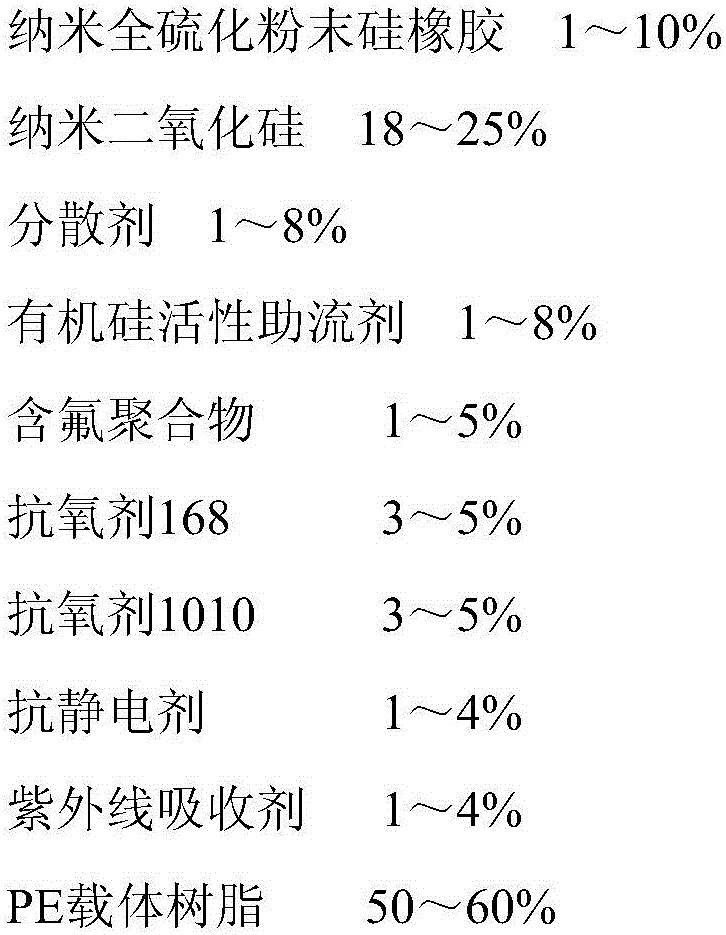

[0048] formula:

[0049]

[0050]

[0051] Preparation:

[0052] 1) Use a cantilever double-helix cone mixer to premix and roughly disperse all components;

[0053] Cantilever double-helix conical mixer, model: DSH-1.5CD, made of stainless steel, the process control speed is 40-50 rpm, and the mixing time is 60 minutes.

[0054] 2) After premixing and coarse dispersion, put the obtained mixed material into a horizontal ball mill for grinding and fine dispersion. Horizontal ball mill model: QM-500, stainless material, the process control speed of the horizontal ball mill is 75-80 revolutions per minute, the temperature is controlled at 80°C, and the stirring time is 80 minutes.

[0055] 3) After the fine dispersion is completed, put the obtained mixed material into the twin-screw granulator to extrude and granulate to strengthen the fine dispersion. The discharge temperature is controlled within the range of 10-30°C, and the process flow rate and output are controlled ...

Embodiment 2

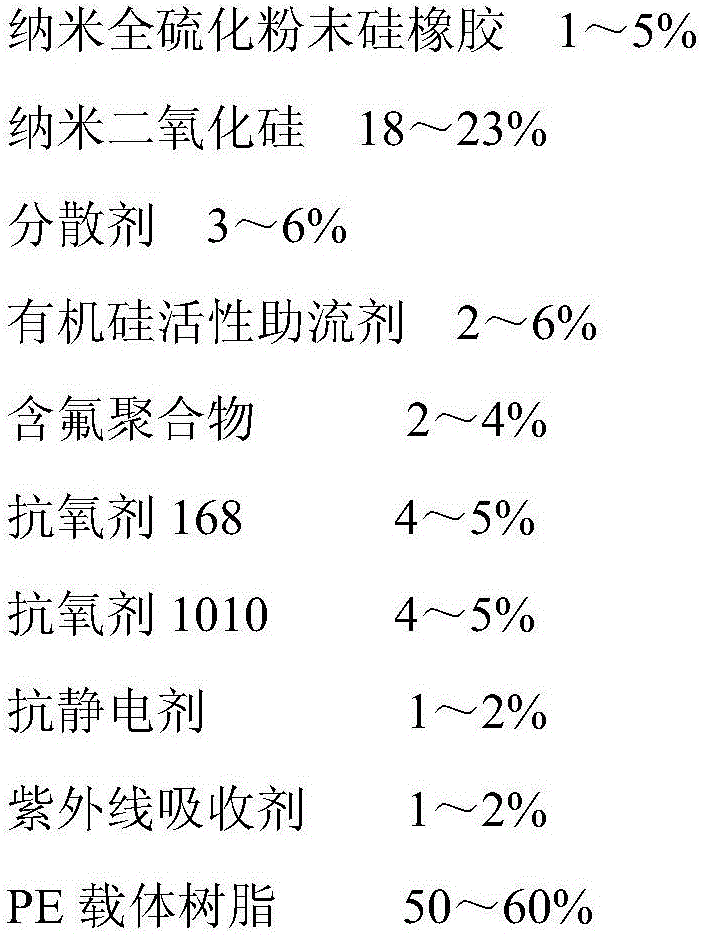

[0063] formula:

[0064]

[0065] The preparation method is the same as in Example 1.

[0066] Table 3 Contrast table between the main index of the auxiliary agent in Example 2 of the present invention and the inspection achievement index

[0067]

[0068]

[0069] Table 4 The indicators achieved after the compound additive product of Example 2 of the present invention is applied to PE

[0070]

[0071]

Embodiment 3

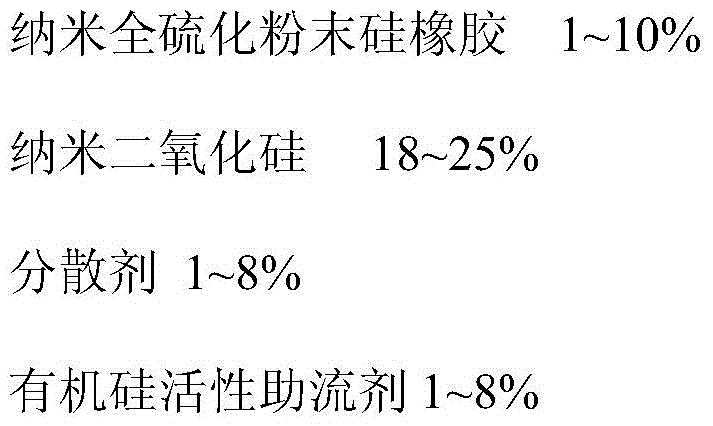

[0073] formula:

[0074]

[0075] The preparation method is the same as in Example 1.

[0076] Table 5 Contrast table between the main index of the auxiliary agent in Example 3 of the present invention and the inspection achievement index

[0077]

[0078]

[0079] Table 6 The indicators achieved after the compound additive product of Example 3 of the present invention is applied to PE

[0080]

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com