Calibration method of x-ray machine tube current

A calibration method and technology of X-ray machines, which are applied in the fields of radiological diagnosis instruments, radiation generation arrangements, medical science, etc., can solve problems such as inaccurate current parameters, improve output accuracy, prolong service life, and reduce calibration time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

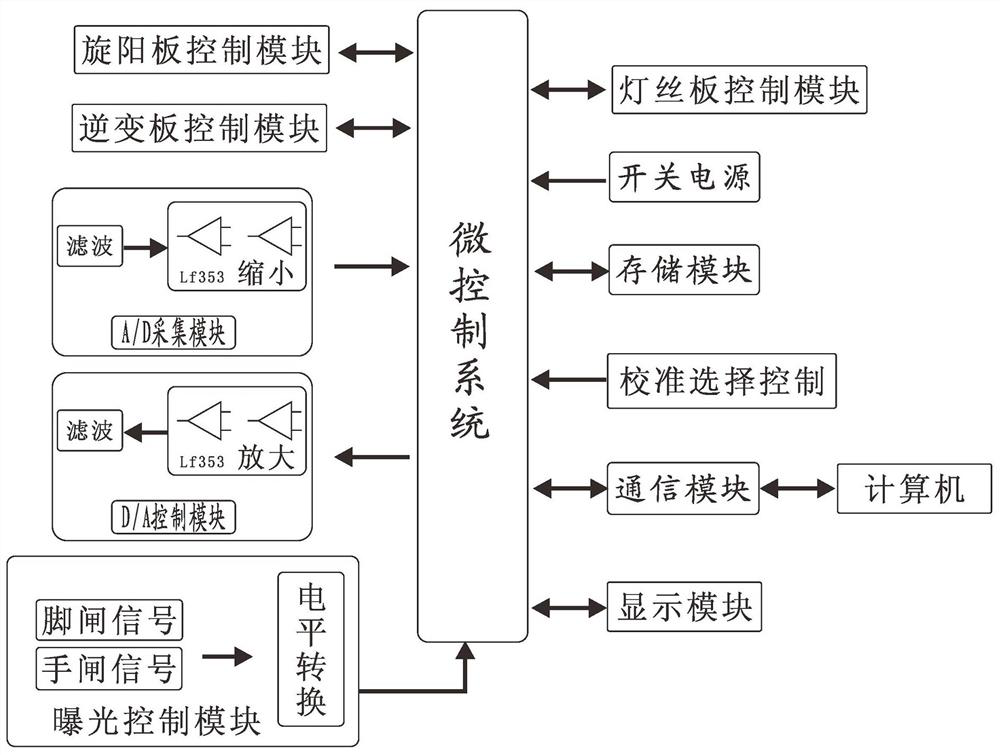

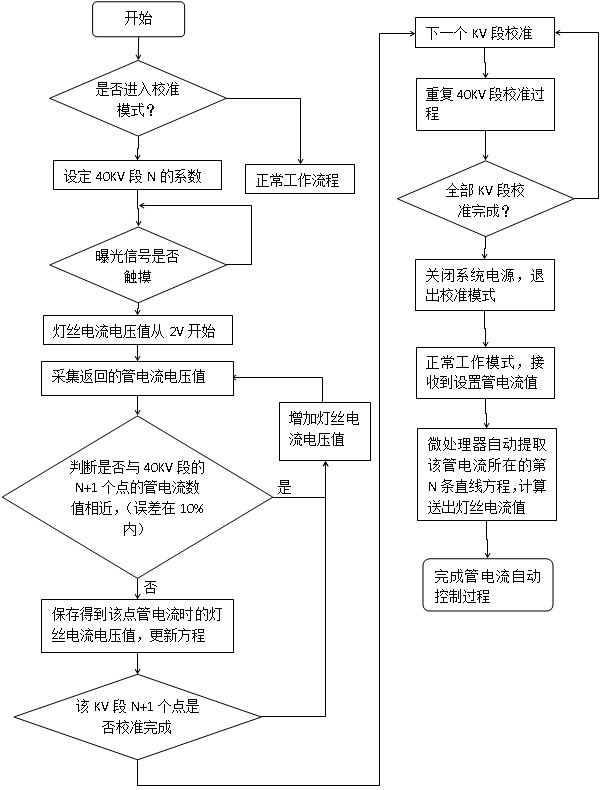

[0022] refer to figure 1 , figure 1 Shown is the structural block diagram of the X-ray machine control system. The control system of the X-ray machine mainly includes A / D acquisition module, D / A control module, micro-control system, touch screen module, communication module, exposure control module and storage module. Among them, the A / D acquisition module is used to collect the voltage signal of the filament current. The AD sampling module is an LF353 integrated operational amplifier filter circuit, which is a proportional operation power reduction circuit with a magnification factor less than 1. After the signal is collected, the voltage value of the input signal can be reduced to Within a suitable range (0-3.3V), prevent the voltage value of the collected filament current from exceeding the input safety voltage (3.3V) of the microcontroller. The D / A control module is an LF353 integrated operational amplifier filter circuit, which is a proportional operational power amplifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com