Method and system for temperature compensation of maglev electric drive for satellite double super-platform

A satellite platform and temperature compensation technology, applied in temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of compensation control method that does not point out the temperature change of the magnetic levitation coil, and achieve the effect of improving the accuracy of current output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

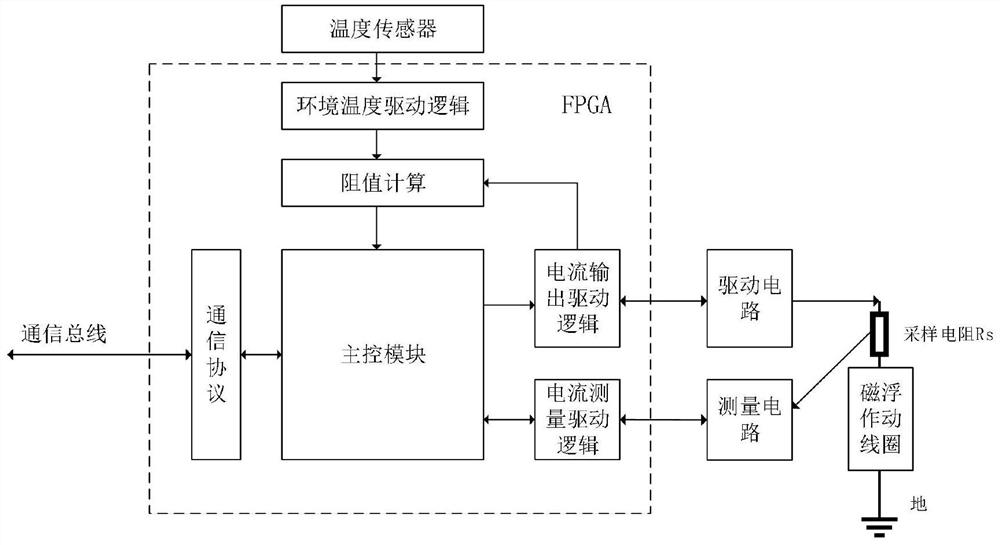

[0033] According to a kind of double-super satellite platform maglev electric drive temperature compensation method provided by the present invention, such as figure 1 shown, including:

[0034] Step M1: Calculate the temperature of the sampling resistor in real time according to the ambient temperature and the preset current value output by the FPGA;

[0035] Step M2: Calculate the real-time resistance value of the sampling resistor according to the temperature of the sampling resistor;

[0036] Step M3: Adjusting the voltage of the magnetic levitation operating coil according to the real-time resistance value of the sampling resistor to control the magnetic levitation operating coil to output a stable current.

[0037] Voltage on the feedback resistor / resistance value of the feedback resistor = current of the magnetic levitation actuation coil, if the resistance value of the feedback resistor changes, the actual output current of the maglev actuation coil decreases, and the...

Embodiment 2

[0059] Embodiment 2 is a modification of embodiment 1

[0060] The present invention provides a corresponding, temperature compensation method. In the present invention, the resistance value of the feedback resistance is calculated in real time, the temperature of the feedback resistance is calculated in real time through the ambient temperature and the output current value, the real-time resistance value of the feedback resistance is calculated according to the temperature of the feedback resistance, and the output current signal is adjusted in real time according to the resistance value to control the maglev The actuating coil outputs a steady current. The present invention eliminates the problem of insufficient accuracy of the feedback measurement current caused by the temperature change of the feedback resistance, and improves the current output accuracy of the maglev operating coil, and is characterized in that:

[0061] A temperature sensor for measuring the ambient tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com