Harmonic current generating device and method for controlling stepless linear output of harmonic current

A technology for harmonic current generators, applied in the field of harmonic sources, can solve the problems of lack of harmonic current, large heat and loss, and lack of harmonic current, so as to achieve low total cost, low energy consumption, and improved key performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

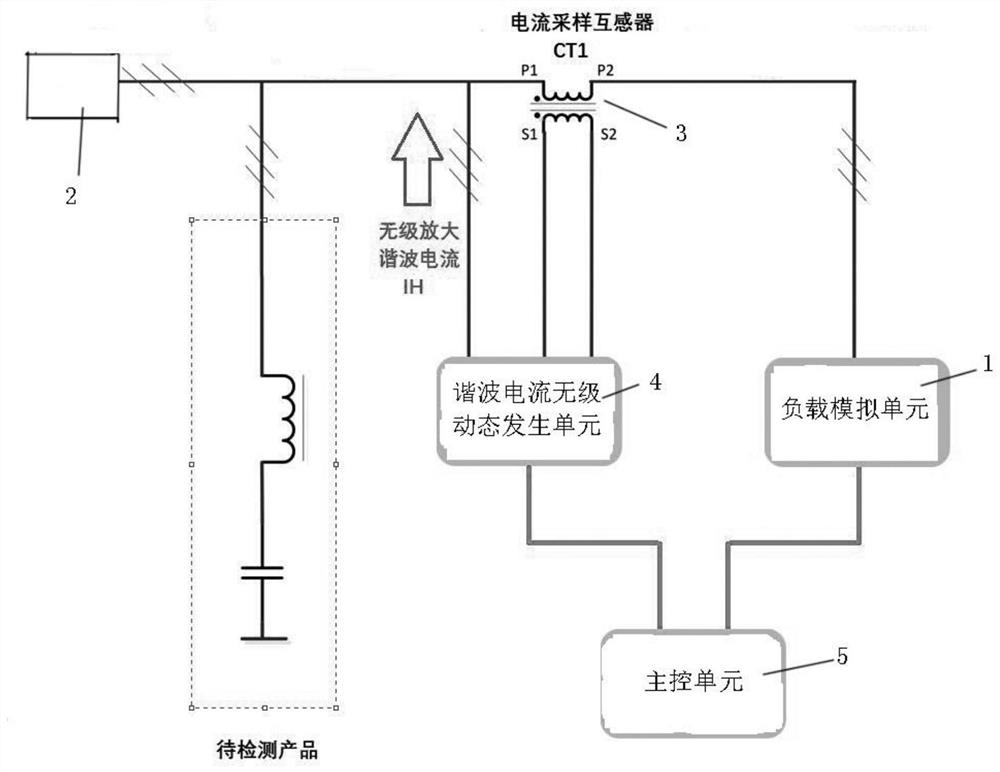

[0030] A harmonic current generating device of the present invention can provide large-capacity controllable harmonic current for reactive power compensation, harmonic filter products or other equipment connected to the power grid, and can restore the working conditions of analog equipment after on-site power supply Dedicated harmonic current source equipment can meet the requirements of manufacturers such as reactors, capacitors, compensation controllers, filters, complete cabinets, etc., for production testing, product output capability and compensation effect testing, or in harmonic environments when connected to the power grid. Practical values such as working performance testing, or factory aging experiments, the common capacity of equipment is 100A ~ 600A, see figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com