Elastic pad for fixing valve control lead-acid battery

A technology of lead-acid batteries and fixed valves, which is applied in the direction of lead-acid batteries, battery components, circuits, etc., can solve the problems of single function, dry electrolyte, battery thermal runaway, uneven force on the bottom of the shell, etc., to improve the main Performance, simplicity of design, effects of delaying thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

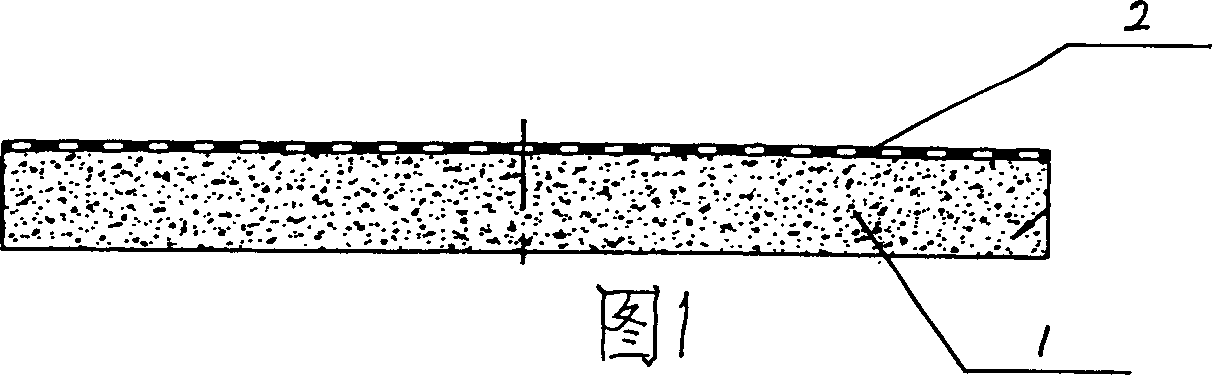

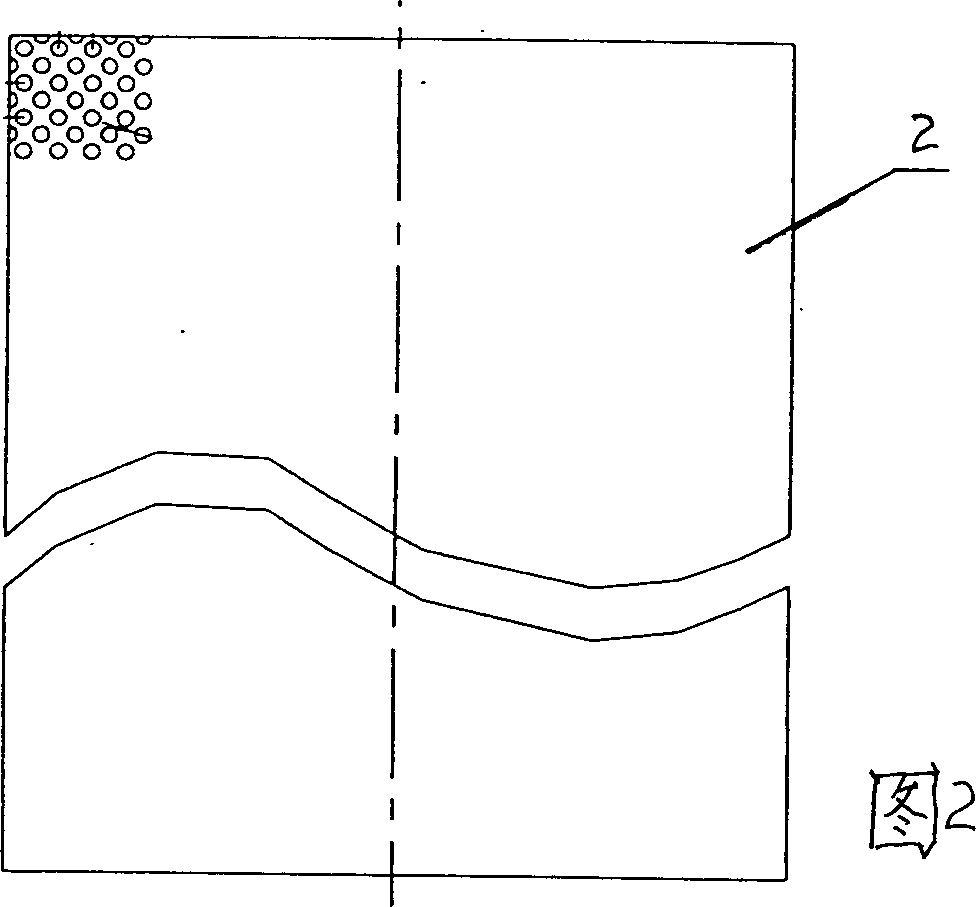

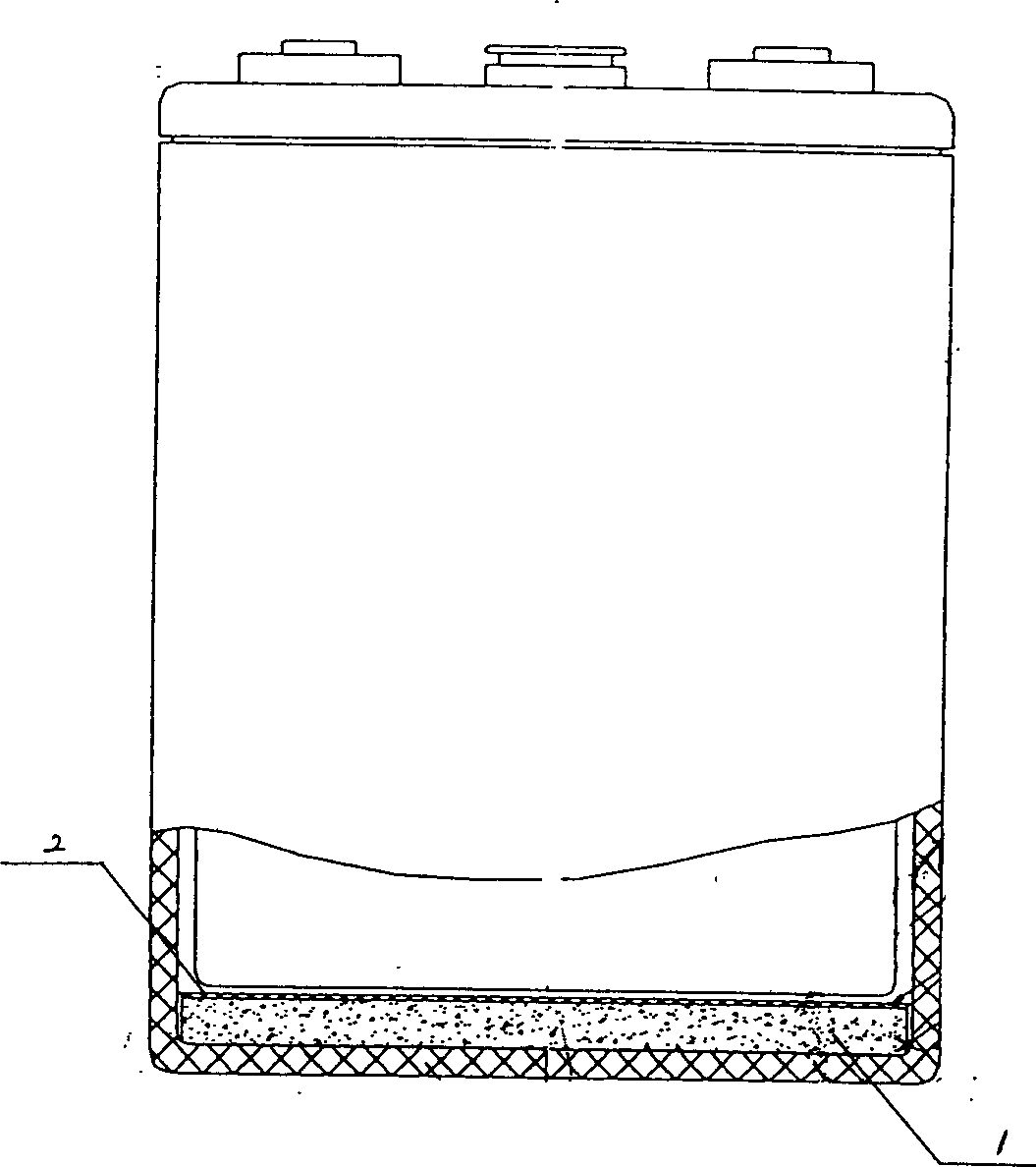

[0016] An elastic bottom pad is used for fixing a valve-regulated lead-acid battery, and the elastic bottom pad 1 is made of elastic glass fiber cotton. A rigid perforated plate 2 is attached to the elastic bottom pad, and the holes on the rigid perforated plate have a spacing of 10 mm and a diameter of 2.4 mm. Put the elastic bottom pad 1 on the bottom of the battery case, cover with the rigid perforated plate 2, and then assemble according to the normal assembly process for fixing the valve-regulated lead-acid battery. In use, since the two poles of the storage battery are very close to the bottom of the housing, the elastic bottom pad and the rigid perforated plate can be prevented from overturning. The elastic bottom pad absorbs and stores a certain amount of electrolyte in advance. After the fixed valve-regulated lead-acid battery has been used for a period of time, the electrolyte decreases and the positive grid elongates. The elastic bottom pad slows down the pressure ...

Embodiment 2

[0018] An elastic bottom pad for fixed valve-regulated lead-acid batteries, the elastic bottom pad is made of acrylic fiber.

Embodiment 3

[0020] Elastic bottom mat for fixed valve-regulated lead-acid batteries, the elastic bottom mat is made of polyester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com