Soft porcelain tile cutting tool bit

A cutting head and cutting blade technology, used in ceramic molding machines, manufacturing tools, etc., can solve the problems of difficult blade cutting, high labor intensity, unfavorable post-construction and other problems, and achieve the effect of good appearance quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

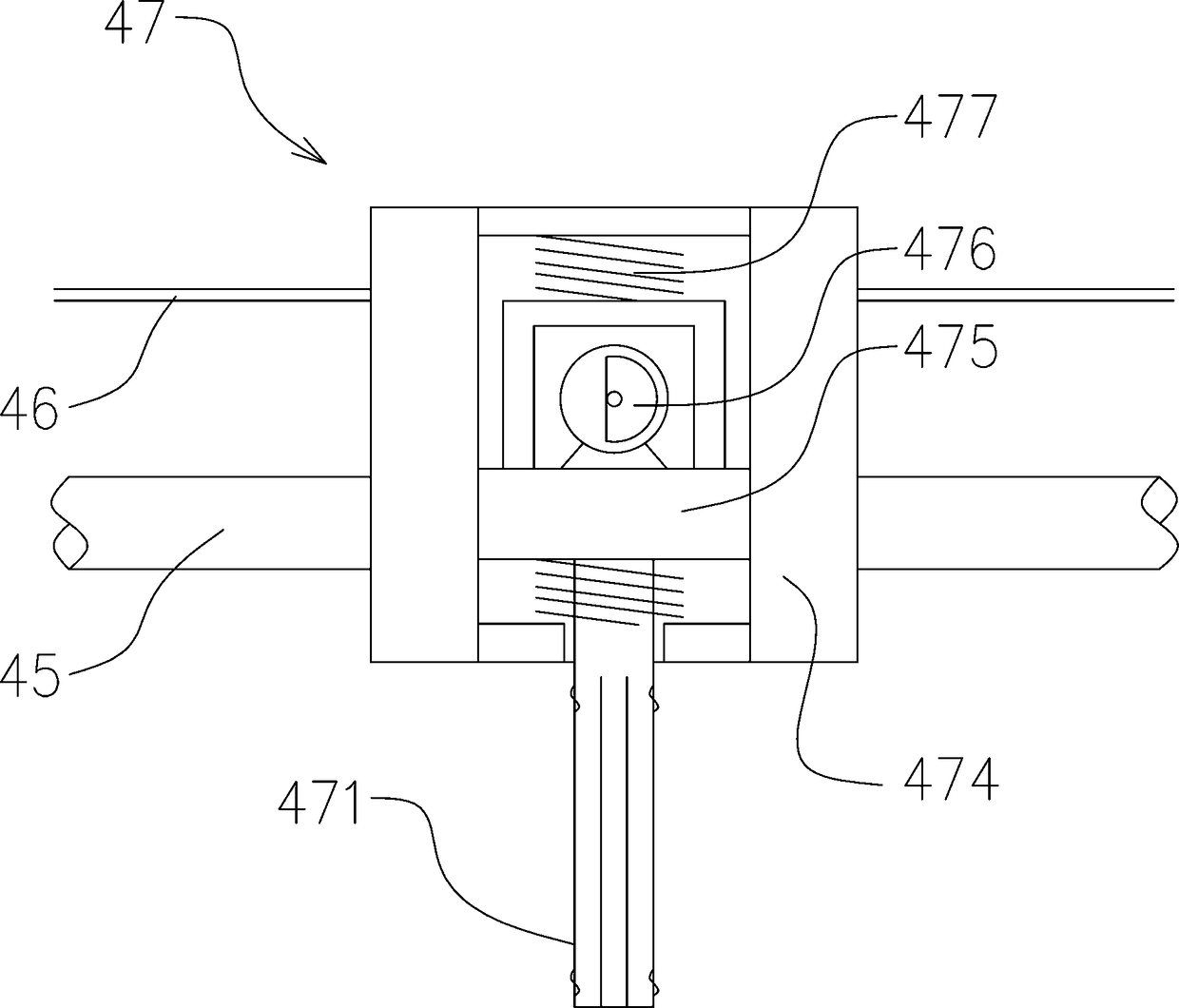

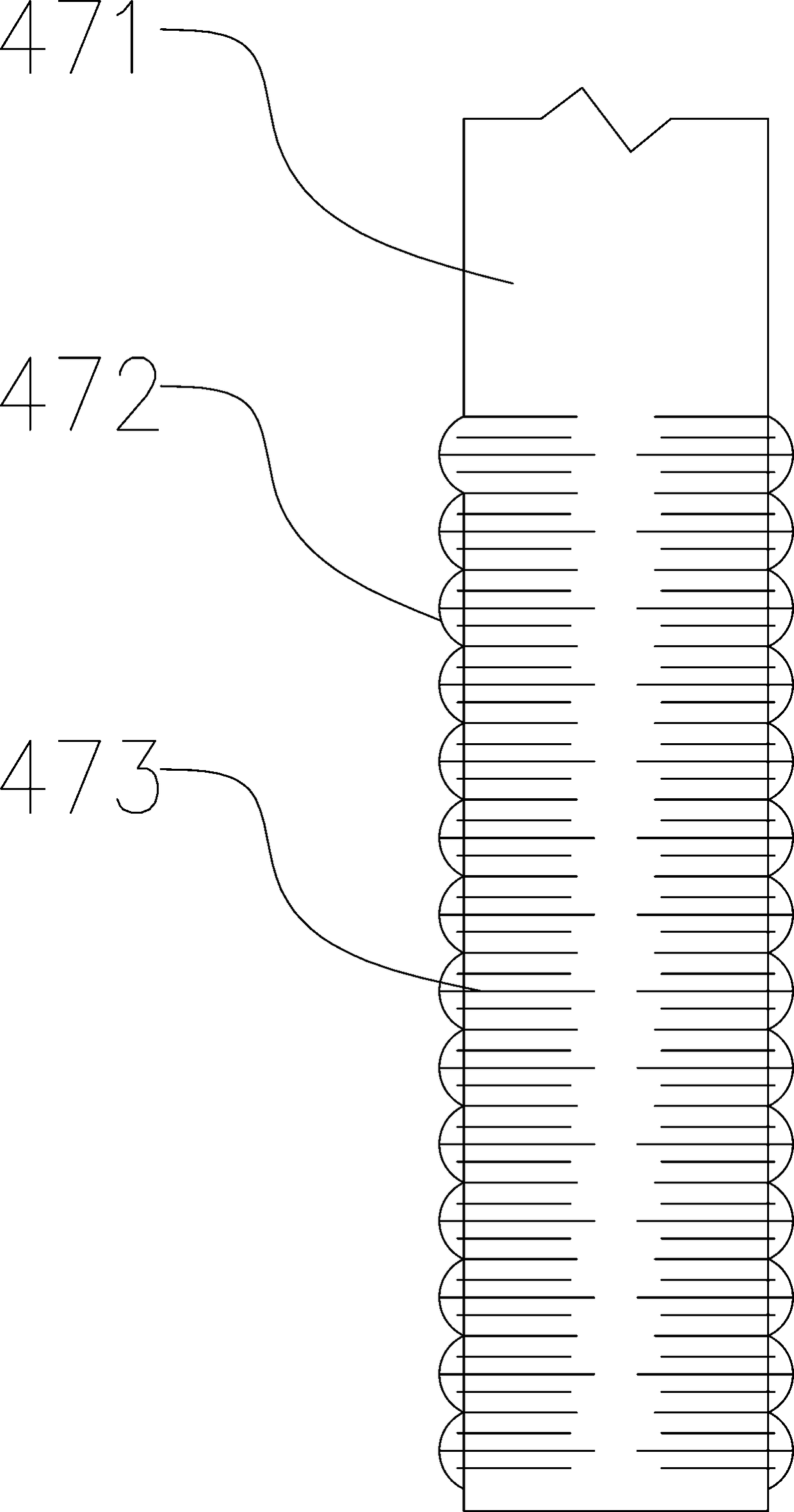

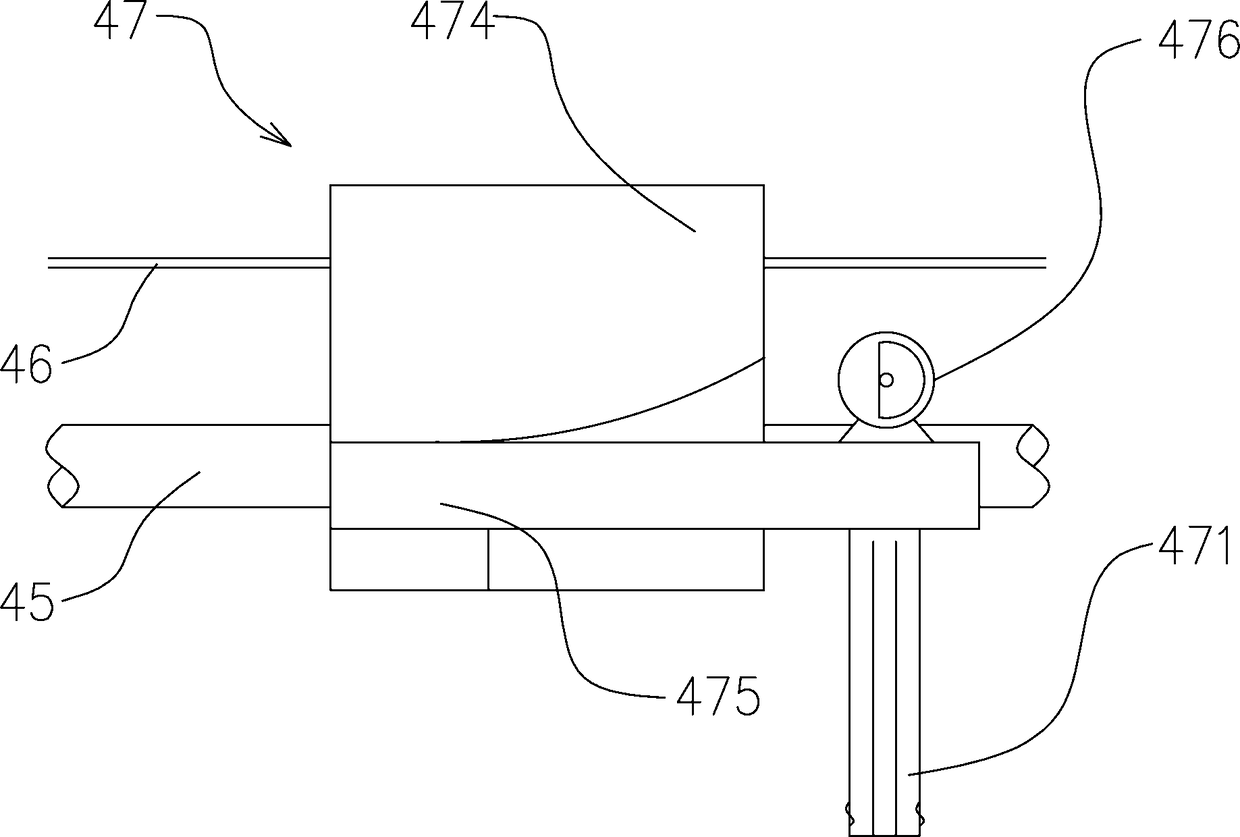

[0024] Such as Figure 1~4 Among them, a kind of soft ceramic sheet cutting cutter head, between the knife seat 475 and the knife seat body 474 is an elastic connection structure, the cutting blade 471 is fixedly connected with the knife seat 475, and the knife seat 475 is fixedly provided with a vibrating device 476 . In a preferred solution, the vibrating device 476 is a piezoelectric vibrator or a motor with an eccentric mass. The vibration frequency of the vibration device 476 is preferably 20-50 Hz. The vibration of the vibrating device 476 drives the cutting blade 471 to reciprocate at a high speed within a small range, thereby cutting the semi-finished soft porcelain 5 . The vibration frequency of the vibrating device 476 is close to the natural frequency of the soft ceramic semi-finished product 5 .

[0025] The preferred solution is as figure 1 Among them, the knife seat body 474 is provided with a chute, the knife seat 475 is slidably installed in the chute, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com